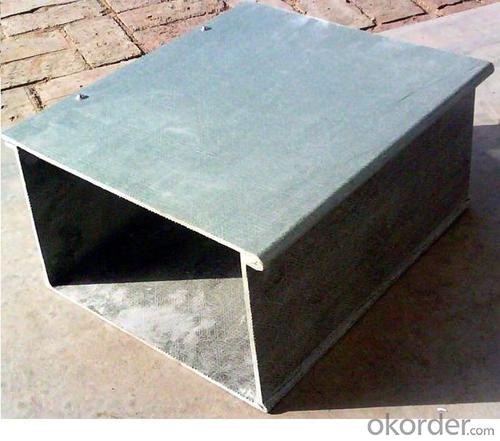

FRP Pultrusion Profiles - Fiber Reinforced Plastic Pultruded Cable Tray

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of FRP Pultruded Cable Tray High Strength and Anti Corrosive

During the pultrusion process, the raw materials are pulled through a heated steel forming die using a continuous pulling device. FRP Pultruded Profile are made of different resins reinforced with fiberglass, by pultrusion technology.

Main Features of FRP Pultruded Cable Tray High Strength and Anti Corrosive

Corrosion resistant

High strength & light weight

Long service life

Fire retardant

Impact resistant

Nonconductive and thermal insulation

Non-magnetic electromagnetic transparency

Dimensional stability, Bright color

Low-maintenance

Main Specification of FRP Pultruded Cable Tray High Strength and Anti Corrosive

Physical Property:

Raw Materials: | · Reinforcement material: Fiberglass, glass mat, continuous strand mat, surfacing mat, needled mat. · Basis material: Unsaturated polyester resin, epoxy resin, vinylester resin |

Color: | Grey, Blue, Yellow, Red, other customized colors |

Density: | 1.5-2.0 g/cm3 |

FRP Cable Tray | Dimension/mm | Cross Section Area/cm2 | Weight Kg/m | ||

L | W | H | |||

001 | 100 | 50 | 3 | 6.32 | 1.169 |

002 | 100 | 100 | 4 | 12.18 | 2.253 |

003 | 150 | 100 | 4 | 14.18 | 2.581 |

004 | 150 | 150 | 5 | 22.50 | 4.163 |

005 | 200 | 100 | 4 | 16.18 | 2.993 |

006 | 200 | 150 | 5 | 25.00 | 4.625 |

007 | 200 | 200 | 6 | 35.78 | 6.619 |

008 | 300 | 100 | 4 | 20.18 | 3.733 |

009 | 300 | 150 | 5 | 30.00 | 5.550 |

010 | 300 | 200 | 6 | 41.78 | 7.729 |

011 | 400 | 100 | 4 | 24.18 | 4.473 |

012 | 400 | 150 | 5 | 35.00 | 6.475 |

013 | 400 | 200 | 6 | 47.78 | 8.839 |

014 | 500 | 100 | 4 | 28.18 | 5.213 |

015 | 500 | 150 | 5 | 40.00 | 7.400 |

016 | 500 | 200 | 6 | 53.78 | 9.949 |

017 | 600 | 100 | 4 | 32.18 | 5.953 |

018 | 600 | 150 | 5 | 45.00 | 8.825 |

019 | 600 | 200 | 6 | 59.78 | 11.059 |

020 | 800 | 100 | 4 | 40.18 | 7.433 |

021 | 800 | 150 | 5 | 55.00 | 10.175 |

022 | 800 | 200 | 6 | 71.78 | 13.279 |

Main Application of FRP Pultruded Cable Tray High Strength and Anti Corrosive

The pultruded FRP Cable Tray is suitable for electrical cable, controll-ing cable, lighting cable and distrib-uting line with the voltage under 10KV. It can be installed with technological line, suspended above the floor or under beam, and also can be installed on the inside or outside wall or the sidewall of tunnel and cable ditch.

Our other FRP composite products are pultrusion fiberglass square tube, frp channel, frp beams, frp round tube, frp flat bar, frp angle, frp cable tray, frp rod, frp rock bolt, frp rebar, frp mortar pipe and other frp profiles.

Contact us for more details.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can FRP pultrusion profiles be used in the construction of stadium seating?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of stadium seating. FRP pultrusion profiles have several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, which is ideal for stadium seating where a large number of seats need to be installed. The lightweight nature of FRP profiles makes them easier to handle and install, reducing the time and effort required for construction. Secondly, FRP pultrusion profiles are highly durable and resistant to corrosion, making them suitable for outdoor applications like stadium seating. They are not prone to rusting, rotting, or degradation from exposure to moisture, UV rays, or chemicals commonly found in stadiums. Additionally, FRP pultrusion profiles are non-conductive, providing an added safety benefit, especially in areas where electrical wiring may be present. This reduces the risk of electric shocks or accidents that can occur with conductive materials. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in designing stadium seating layouts. They can be manufactured in various shapes, sizes, and colors to match the aesthetic and functional requirements of the stadium. Lastly, FRP pultrusion profiles have a long service life with low maintenance requirements, reducing the overall cost of ownership for stadium seating. This makes them a cost-effective choice in the long run. In conclusion, FRP pultrusion profiles are an excellent choice for the construction of stadium seating due to their lightweight, durable, non-conductive, customizable, and cost-effective nature.

- Q: What are the typical applications for FRP pultrusion profiles?

- FRP pultrusion profiles have a wide range of uses in different industries. In construction, they are commonly used for structural components like beams, columns, and platforms. These profiles have a high strength-to-weight ratio, are corrosion resistant, and durable, making them perfect for long-lasting, low-maintenance infrastructure. In transportation, FRP pultrusion profiles are used to manufacture lightweight components for buses, trucks, railcars, and wind turbines. Their lightweight nature helps reduce fuel consumption and increase energy efficiency. Additionally, they can withstand chemicals, moisture, and UV radiation, ensuring their durability in harsh environments. In the electrical and power distribution field, FRP pultrusion profiles are utilized for manufacturing insulating supports, cable trays, and ladder racks. These profiles offer excellent electrical insulation properties, making them a safe and reliable choice for electrical installations. Furthermore, their non-conductive nature helps prevent electrical accidents and eliminates the risk of electric shock. In the marine industry, FRP pultrusion profiles are ideal for manufacturing boat hulls, decks, and other marine components due to their resistance to saltwater corrosion. Their high strength and stiffness enable them to withstand the tough conditions of the marine environment. Additionally, FRP pultrusion profiles are used in the chemical processing industry for manufacturing tanks, pipes, and platforms. They are resistant to various chemicals and corrosive substances, ensuring the equipment's integrity and enhancing safety in chemical plants. Overall, FRP pultrusion profiles have diverse applications in industries such as construction, transportation, electrical, marine, and chemical processing. Their unique properties make them a versatile and dependable choice for various structural and functional needs.

- Q: Can FRP pultrusion profiles be used in aerospace applications?

- FRP pultrusion profiles are applicable in aerospace applications. They possess numerous advantages that render them suitable for use in this field. Firstly, their exceptional strength-to-weight ratios are crucial in the aerospace industry as they contribute to weight reduction and fuel efficiency improvement. Secondly, FRP materials display high resistance to corrosion, making them suitable for enduring exposure to harsh environments like high altitudes and extreme temperatures. Additionally, FRP pultrusion profiles provide design flexibility, allowing for the production of intricate shapes and geometries. This flexibility enables aerospace engineers to customize the profiles according to specific requirements and optimize their performance. Moreover, FRP materials exhibit low thermal conductivity, which aids in insulation applications and minimizes heat transfer. Lastly, FRP pultrusion profiles have demonstrated commendable fatigue resistance, a crucial factor for aerospace applications subjected to cyclic loading. Overall, these properties establish FRP pultrusion profiles as a viable option for various aerospace components, including structural members, interior parts, and electrical enclosures.

- Q: Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals used in oil refineries. The composition of FRP profiles includes a combination of high-strength fibers, such as fiberglass, carbon fibers, or aramid fibers, embedded in a polymer resin matrix. This unique construction provides excellent resistance to a wide range of chemicals, including those commonly found in oil refineries. The polymer resin matrix used in FRP profiles can be carefully selected to withstand harsh chemical environments. For instance, vinyl ester or epoxy resins are often used in the manufacturing of FRP profiles for oil refinery applications due to their superior chemical resistance properties. Moreover, FRP pultrusion profiles are inherently corrosion-resistant, unlike traditional materials like steel or concrete, which can deteriorate when exposed to aggressive chemicals found in oil refineries. This corrosion resistance ensures the long-term durability and reliability of FRP profiles in such environments. Additionally, FRP profiles offer several other advantages in oil refinery applications, including high strength-to-weight ratio, electrical insulation, non-magnetic properties, and ease of installation. These characteristics make FRP pultrusion profiles an ideal choice for various structural, piping, and equipment applications within oil refineries. However, it is essential to consider the specific chemicals and concentrations involved in a particular oil refinery application. While FRP profiles generally exhibit excellent resistance to a wide range of chemicals, there might be certain highly concentrated or specialized chemicals that could potentially affect their performance. In such cases, it is advisable to consult with FRP manufacturers or experts who can provide tailored solutions to meet the specific chemical resistance requirements of the oil refinery.

- Q: What is the shear strength of FRP pultrusion profiles?

- The shear strength of FRP (Fiber Reinforced Plastic) pultrusion profiles can vary depending on several factors such as the type and quality of fibers used, the resin matrix, and the manufacturing process. Generally, FRP pultrusion profiles have high shear strength due to the continuous fibers running along the length of the profile. The shear strength of FRP pultrusion profiles is typically determined through testing according to industry standards such as ASTM D2344 or ISO 14129. These tests involve subjecting the profile to a shear force until failure occurs, allowing for the calculation of the shear strength. The exact shear strength values for FRP pultrusion profiles can vary significantly depending on the specific composition and design of the profile. However, it is not uncommon for FRP pultrusion profiles to exhibit shear strengths in the range of 50-150 MPa (megapascals) or higher. This makes them suitable for a wide range of structural applications where shear forces are prevalent. It is important to note that the shear strength of FRP pultrusion profiles can be influenced by factors such as temperature, moisture, and exposure to chemicals. Therefore, it is essential to consider the specific environmental conditions and requirements of the application when determining the appropriate FRP profile to be used. Overall, FRP pultrusion profiles are known for their excellent shear strength, which contributes to their popularity and effectiveness in various industries such as construction, transportation, and infrastructure.

- Q: How do FRP pultrusion profiles handle torsion loads?

- FRP pultrusion profiles are designed to handle torsion loads effectively due to their inherent properties. The continuous fibers in the profile provide excellent resistance to torsional forces, ensuring high strength and stability. The pultrusion manufacturing process also allows for precise control over the fiber orientation, resulting in profiles that can efficiently handle torsion loads without compromising their structural integrity.

- Q: Can FRP pultrusion profiles be used in the aerospace and aviation industry?

- Yes, FRP pultrusion profiles can be used in the aerospace and aviation industry. These profiles offer several advantages such as high strength-to-weight ratio, excellent corrosion resistance, and electrical insulation properties. They can be used in various applications including aircraft interiors, structural components, and electrical systems. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them suitable for use in the aerospace and aviation industry.

- Q: Are FRP pultrusion profiles resistant to electrical surges or lightning strikes?

- FRP pultrusion profiles have inherent electrical insulation properties due to their composition of fiberglass reinforcement and resin matrix. This insulation makes them resistant to electrical surges and lightning strikes to some extent. However, it is important to note that no material can provide absolute protection against extremely high voltage electrical surges or direct lightning strikes. In such cases, additional measures like grounding and lightning protection systems are necessary to ensure the safety of structures or equipment. Therefore, while FRP pultrusion profiles offer some level of resistance to electrical surges and lightning strikes, it is advisable to consult with experts and adhere to relevant safety standards when designing and installing electrical systems in areas prone to such events.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in food packaging. FRP materials are known for their excellent resistance to a wide range of chemicals, including those commonly used in food packaging such as acids, bases, solvents, and oils. This chemical resistance makes FRP pultrusion profiles a suitable choice for applications involving contact with food packaging materials. However, it is important to note that the specific resistance of FRP profiles may vary depending on the formulation and type of resin used. Therefore, it is advisable to consult with the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are suitable for the specific chemicals used in the food packaging industry.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in pharmaceutical packaging. FRP pultrusion profiles are made of a combination of reinforced fibers and a polymer resin matrix, which provides them with excellent chemical resistance properties. The polymer resin used in FRP profiles is typically selected to be compatible with a wide range of chemicals, including those commonly used in pharmaceutical packaging. FRP profiles have been extensively used in various industries, including pharmaceuticals, due to their high chemical resistance. They are capable of withstanding exposure to a wide range of chemicals, such as acids, bases, solvents, and other aggressive substances commonly found in pharmaceutical packaging processes. This resistance helps protect the integrity of the packaging and ensures that there is no contamination or degradation of the pharmaceutical products. Additionally, FRP pultrusion profiles are also resistant to corrosion, which is another advantage in the pharmaceutical industry where aggressive chemicals may be present. This resistance to corrosion further enhances the durability and longevity of the FRP profiles, making them a reliable choice for pharmaceutical packaging applications. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles may vary depending on the type and concentration of the chemicals being used. Therefore, it is recommended to consult the manufacturer or supplier of the FRP profiles to ensure their compatibility with the specific chemicals used in pharmaceutical packaging.

Send your message to us

FRP Pultrusion Profiles - Fiber Reinforced Plastic Pultruded Cable Tray

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords