FRP Pultrusion Profiles - FRP Gratings, Fiberglass Solid Grilles, Water Resistance Steel Grating with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

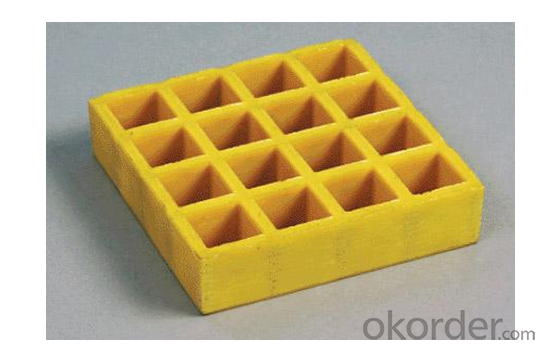

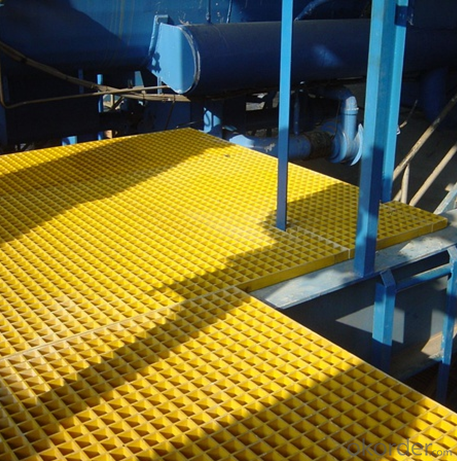

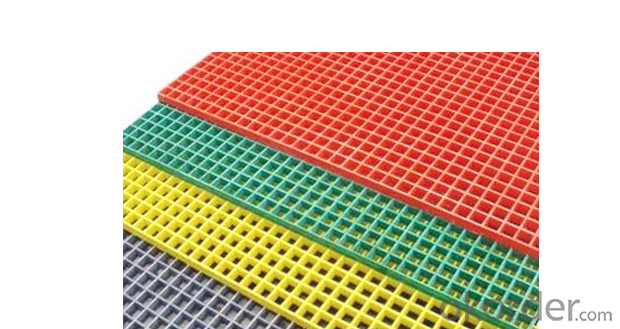

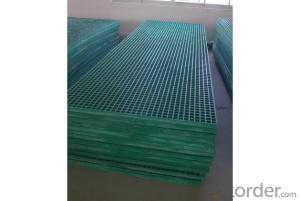

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

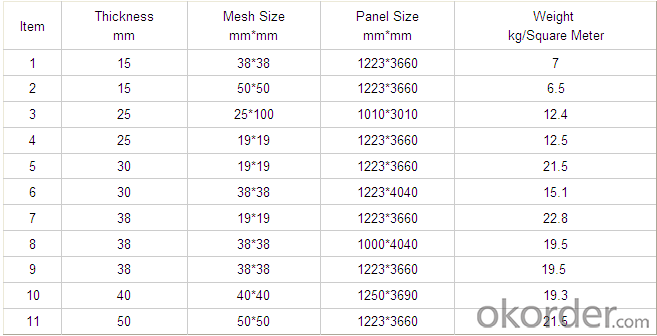

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in the renewable energy sector?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the renewable energy sector. These profiles possess excellent strength-to-weight ratio, corrosion resistance, and durability, making them ideal for various renewable energy applications. They can be utilized in the manufacturing of wind turbine blades, solar panel frames, structural components for hydroelectric power systems, and much more. Additionally, FRP pultrusion profiles offer design flexibility, allowing for customization to specific project requirements.

- Q: Are FRP pultrusion profiles resistant to moisture or humidity?

- Yes, FRP pultrusion profiles are highly resistant to moisture and humidity. The combination of fiberglass reinforcement and resin matrix used in their construction makes them non-corrosive and impervious to water absorption. This inherent resistance ensures their durability and performance in humid or moist environments without compromising their structural integrity.

- Q: Can FRP pultrusion profiles be used in the production of electrical cabinets?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the production of electrical cabinets. FRP pultrusion profiles provide excellent electrical insulation properties, high strength-to-weight ratio, and resistance to corrosion, making them suitable for use in electrical cabinets where electrical safety and durability are essential.

- Q: Can FRP pultrusion profiles be used in the construction of elevated walkways?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of elevated walkways. FRP pultrusion profiles are lightweight yet strong, making them an ideal choice for creating durable and long-lasting walkways that can withstand heavy foot traffic. They offer excellent corrosion resistance, making them suitable for outdoor applications where exposure to moisture, chemicals, and UV radiation is a concern. FRP pultrusion profiles also have high strength-to-weight ratios, allowing for easy installation and reducing the structural load on the supporting elements. Moreover, FRP profiles are non-conductive, making them a safer option for walkways in areas where electrical hazards are present. Overall, FRP pultrusion profiles offer numerous advantages that make them well-suited for the construction of elevated walkways.

- Q: Are FRP pultrusion profiles resistant to ultraviolet radiation?

- Yes, FRP pultrusion profiles are generally resistant to ultraviolet radiation. The combination of the composite material and the resin used in pultrusion manufacturing provides excellent UV resistance, making them suitable for outdoor applications.

- Q: Are FRP pultrusion profiles impact resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high impact resistance. The combination of strong reinforcing fibers and a polymer matrix makes them highly durable and able to withstand significant impact forces without breaking or deforming.

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: How do FRP pultrusion profiles handle compression loads?

- FRP (Fiber-Reinforced Polymer) pultrusion profiles handle compression loads in a unique and effective way due to their structure and material composition. Pultruded profiles are made by pulling continuous fibers, such as glass or carbon, through a resin bath and then through a heated die, where the resin is cured and the shape is formed. When it comes to compression loads, FRP pultrusion profiles exhibit excellent performance. The continuous fibers embedded within the resin matrix make the profiles highly stiff and strong, allowing them to effectively resist compressive forces. The fibers distribute the load evenly along the length of the profile, preventing localized failure and ensuring overall structural integrity. The fiber reinforcement in FRP pultrusion profiles also provides excellent resistance against buckling. Buckling is a phenomenon where a slender structural member fails due to excessive compressive loads causing instability. The high strength-to-weight ratio of the fibers helps prevent buckling and allows the profiles to withstand substantial compression forces without compromising their structural integrity. Additionally, the resin matrix in FRP pultrusion profiles plays a crucial role in handling compression loads. The resin provides a protective layer around the fibers, preventing them from being damaged or fractured under compressive forces. It also acts as a load transfer medium, distributing the compressive load to the fibers, which then carry the load throughout the entire profile. Overall, FRP pultrusion profiles are well-suited for handling compression loads due to their fiber reinforcement and resin matrix. They offer high strength, stiffness, and resistance to buckling, making them an ideal choice for a wide range of applications where compression loads are a concern.

- Q: Are FRP pultrusion profiles resistant to chemicals used in chemical plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to the chemicals typically used in chemical plants. The combination of reinforced fibers and a polymer matrix in FRP profiles provides excellent resistance to a wide range of corrosive substances, making them an ideal choice for chemical plant applications.

- Q: Are FRP pultrusion profiles UV resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally UV resistant. The composite materials used in pultrusion manufacturing typically have inherent resistance to ultraviolet (UV) radiation. Additionally, manufacturers often incorporate UV inhibitors and protective coatings to enhance the UV resistance of the profiles, making them suitable for outdoor applications exposed to sunlight and other environmental conditions.

Send your message to us

FRP Pultrusion Profiles - FRP Gratings, Fiberglass Solid Grilles, Water Resistance Steel Grating with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords