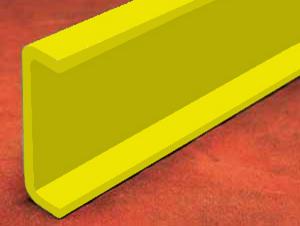

FRP Pultrusion Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Meters m.t.

- Supply Capability:

- 9999999Meters m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of FRP Pultrusion Profile

FRP fiberglass pultrusion profile

1.ISO 9001

2.High Strength and insulation

3.High Corrosion Resistance

4.Any shape

Description of FRP Pultrusion Profile

1.FRP products are with low weight and high strength.

density:1.5-2, 1/4 of carbon steel, but the same tensile strength with carbon steel. So the FRP products can be widely used in aerospace, rockets,high-pressure container, and so on.

2.Great decay resistance

FRP product has good decay resistance, it has good ability to resist to air, water and general concentration of acid, alkali, salt, and a variety of solvent oil. So, it also can be used in chemical anticorrosion to replace steel, wood and other mentals.

3.Good electrical performance

FRP is a good insulation material, it can keeps good dielectric properties under high frequency.

Good microwave permeability, so it is widely used to make radar antenna mask.

4.good thermal performance

FRP is with low thermal conductivity,in room temperature, it's 1.25~1.67kJ/(m·h·K), is excellent insulation material.

5.Good plasticity

The material can be made into everything according to consumers' request.

Packaging & Delivery of FRP Pultrusion Profile

Packaging Detail: on the pallet

Delivery Detail: within 30 days

- Q: How do FRP pultrusion profiles perform in earthquake-prone areas?

- When it comes to performance in earthquake-prone areas, FRP (Fiber Reinforced Polymer) pultrusion profiles have numerous advantages. To start with, their high strength-to-weight ratio is well-known. This means that they are lightweight compared to traditional construction materials like steel or concrete, yet still offer significant strength. This characteristic is crucial in earthquake-prone areas as it reduces the overall mass of the structure, minimizing the inertial forces generated during seismic events. As a result, FRP profiles can effectively withstand and absorb the energy released during an earthquake, reducing the risk of structural damage or collapse. Additionally, FRP pultrusion profiles exhibit excellent durability and resistance to corrosion. Unlike steel, they are not susceptible to rust or other forms of degradation caused by moisture or chemicals commonly found in earthquake-prone areas. This resistance to corrosion ensures the long-term performance and reliability of FRP profiles, minimizing the need for costly maintenance and repairs. Furthermore, FRP pultrusion profiles demonstrate high flexibility and ductility. These characteristics allow them to deform and absorb energy without fracturing or breaking, which is particularly advantageous during seismic events. By dissipating the energy generated by the earthquake, FRP profiles help protect the integrity of the structure and prevent catastrophic failures. Lastly, FRP pultrusion profiles are non-conductive materials, meaning they do not conduct electricity. This feature is important in earthquake-prone areas where electrical infrastructure can be vulnerable to damage. The non-conductive nature of FRP profiles reduces the risk of electrical faults or fires caused by seismic activity. In conclusion, FRP pultrusion profiles provide a range of performance advantages in earthquake-prone areas. Their lightweight, high strength, durability, flexibility, and non-conductive properties make them a reliable and effective choice for construction in regions prone to seismic activity.

- Q: Can FRP pultrusion profiles be used in the telecommunications and data communication industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the telecommunications and data communication industry. FRP pultruded profiles have several advantages that make them suitable for use in this industry. Firstly, FRP pultrusion profiles offer excellent electrical insulation properties, making them ideal for applications in the telecommunications and data communication industry where electrical conductivity needs to be minimized. FRP profiles do not conduct electricity, ensuring that there are no interference or grounding issues that could disrupt the transmission of data. Secondly, FRP pultrusion profiles are lightweight yet strong, providing a high strength-to-weight ratio. This makes them suitable for use in the construction of communication towers, antenna supports, and satellite dish mountings, where the profiles need to withstand wind loads and other environmental stresses. Additionally, FRP profiles have excellent corrosion resistance, which is crucial in the telecommunications and data communication industry where equipment is often exposed to harsh outdoor environments. Unlike traditional materials such as steel or aluminum, FRP profiles do not rust or corrode, ensuring the longevity and reliability of the infrastructure. Furthermore, FRP profiles can be easily customized and manufactured in various shapes and sizes to meet the specific requirements of telecommunications and data communication applications. This flexibility allows for the design and construction of complex structures that can accommodate different equipment and technologies. Overall, FRP pultrusion profiles offer a range of benefits that make them well-suited for use in the telecommunications and data communication industry. Their electrical insulation properties, lightweight yet strong nature, corrosion resistance, and flexibility in design make them a reliable choice for supporting infrastructure in this sector.

- Q: How do FRP pultrusion profiles perform in extreme temperatures?

- FRP pultrusion profiles are known for their excellent performance in extreme temperatures. Due to their unique composition of fiberglass and resin matrix, they are highly resistant to thermal expansion and contraction. This means that even in extremely cold or hot environments, FRP profiles maintain their structural integrity without warping or deforming. In high-temperature conditions, FRP pultrusion profiles exhibit remarkable dimensional stability and do not soften or melt like some other materials. They have a high glass transition temperature, which allows them to withstand even the most extreme heat without losing their strength or shape. This makes FRP profiles suitable for applications such as furnace components, exhaust systems, and industrial ovens. On the other hand, in extremely cold temperatures, FRP pultrusion profiles remain tough and durable. They do not become brittle or prone to cracking like traditional materials such as metal or concrete. This makes them suitable for use in cold storage facilities, refrigerated trucks, and other low-temperature environments. Furthermore, FRP pultrusion profiles have excellent resistance to chemical corrosion. They are not affected by exposure to various chemicals or solvents, making them suitable for use in harsh chemical processing environments. This resistance to chemical corrosion also extends to extreme temperatures, further enhancing their performance in such conditions. Overall, FRP pultrusion profiles have proven to be reliable and versatile materials in extreme temperature environments. Their ability to maintain structural integrity, dimensional stability, and resistance to chemical corrosion make them a preferred choice for various industries and applications where temperature extremes are a concern.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical pumps?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of chemical pumps. FRP (Fiber Reinforced Plastic) offers excellent chemical resistance, high strength, and corrosion resistance, making it an ideal material for chemical pump applications. The pultrusion process ensures consistent quality and dimensional stability, allowing for precise manufacturing of pump components. Additionally, FRP pultrusion profiles have a long service life and require minimal maintenance, making them a cost-effective choice for chemical pump manufacturers.

- Q: What is the fatigue resistance of FRP pultrusion profiles?

- The fatigue resistance of FRP pultrusion profiles is generally high due to the inherent properties of the material, such as its high strength-to-weight ratio, excellent stiffness, and resistance to corrosion. However, the specific fatigue resistance of FRP pultrusion profiles can vary depending on factors such as the type of resin used, the manufacturing process, and the design considerations. Overall, FRP pultrusion profiles are known to exhibit good fatigue performance and can withstand repeated loading cycles without significant degradation in mechanical properties.

- Q: Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP pultrusion profiles are highly resistant to chemicals used in oil refineries. The combination of their fiberglass reinforcement and resin matrix makes them impervious to many corrosive substances, ensuring long-term durability and performance in such harsh environments.

- Q: Can FRP pultrusion profiles be used in the telecommunications industry?

- Indeed, the telecommunications industry can use FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles have numerous advantages that make them appropriate for telecommunications applications. Firstly, FRP pultrusion profiles are both lightweight and immensely strong, making them perfect for telecommunications infrastructure. They can be utilized in the design and construction of structures such as antenna mounts, support poles, cable trays, and enclosures. The lightweight nature of FRP profiles simplifies installation and maintenance, reducing the overall cost and effort involved in establishing and upkeeping telecommunications systems. Secondly, FRP pultrusion profiles possess exceptional corrosion resistance properties. This is especially crucial in the telecommunications industry, as infrastructure components are frequently exposed to harsh weather conditions and environmental factors. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, guaranteeing their durability and dependability in telecommunications applications. Moreover, FRP pultrusion profiles provide electrical insulation properties, which are essential in the telecommunications industry. These profiles do not conduct electricity, making them suitable for applications requiring electrical grounding or isolation. This characteristic ensures the safety of telecommunications equipment and personnel. Furthermore, FRP pultrusion profiles can be tailored to meet specific project requirements. They can be engineered with specific dimensions, shapes, and load-bearing capacities as needed. This flexibility allows for the design and fabrication of telecommunications infrastructure that meets the unique demands of each project. In conclusion, FRP pultrusion profiles are well-suited for telecommunications applications due to their lightweight, high strength, corrosion resistance, electrical insulation properties, and customization options. These profiles offer a reliable and cost-effective solution for various applications within the telecommunications sector.

- Q: Are FRP pultrusion profiles resistant to moisture or humidity?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to moisture and humidity. The pultrusion process involves impregnating continuous fibers with a polymer resin, resulting in a strong and durable composite material. This composite is inherently moisture-resistant and does not absorb water like traditional materials such as wood or metal. Additionally, FRP pultrusion profiles have a low coefficient of thermal expansion, meaning they are less likely to expand or contract under varying levels of humidity. This resistance to moisture and humidity makes FRP pultrusion profiles suitable for a wide range of applications, including outdoor structures, marine environments, and other moisture-prone areas.

- Q: What are the features of Glass Fiber Reinforced Plastic Pultruded materials and chairs?

- Glass reinforced plastic extruded section bar has the characteristics of unlimited length, high utilization rate of raw material, corrosion resistance, good weatherability and long service life

- Q: Are FRP pultrusion profiles resistant to chemicals used in power plants?

- Yes, FRP pultrusion profiles are highly resistant to chemicals commonly used in power plants. The composite materials used in their construction, such as fiberglass and resin, offer excellent resistance to corrosion and chemical attack. This makes FRP pultrusion profiles a durable and reliable choice for various applications in power plants, including structural components and equipment.

1. Manufacturer Overview

| Location | Qingdao, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 80 Million |

| Main Markets | Mid East; South America;Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 5000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Pultrusion Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Meters m.t.

- Supply Capability:

- 9999999Meters m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords