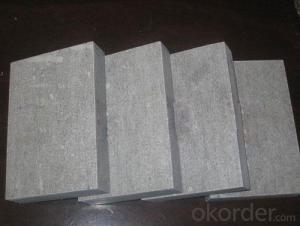

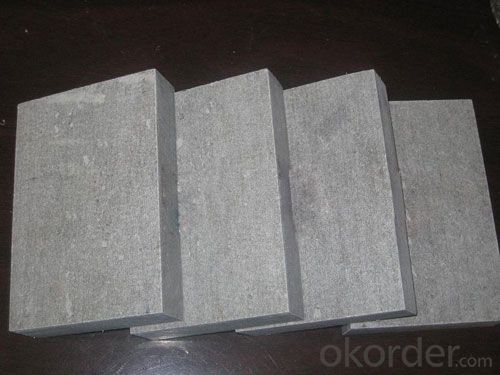

Fiber Cement Boards For Interior Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q: As an artist, I'm experimenting with plaster and cement.As a resident of a temperate zone, I'm wondering about temperature, curing times, and bonding to substrate.I'm working on square pieces of particle board. I rough up the surface with a wire brush to improve bonding to the substrate.Both plaster and cement create heat as they solidify. Are either impaired by a low (and possibly sub-freezing) temperature? I have a makeshift oven that can reach 110 to 120 degrees (F) regardless of the outside temperature. Will heating cement or plaster to this extent improve its ability to bond to wood? Might it only reduce setting time?

- The British give this name to modern day cement. Ordinary Portland cement,sulphate resistant cement, white cement and Grey cement and so on. Most have chemical name but Portland is a patent name.

- Q: What can I put on the two walls that have the cement backer board? Is there only certain things that I can put on them. They are about 3 ft. away from the stove. What is the code for this. I am at a loss, but I need to do something about this. Anyone know about wood stove codes. Thanks...

- You need to check with your local codes for options and requirements. I would say that whatever material you use , it needs to be fire retardant. Perhaps a stone tile, or extend the ceramic floor tiles onto the wall. Is the flue for the stove going into the wall, or does it go up into the ceiling. That will also impact your choices of materials

- Q: There is a problem like your team to ask the partition wall have what form in addition to light steel keel gypsum board there are no other

- Factory or office, then you can use Caigang sandwich panels, the family can use colored glass sliding door or do closet to do partition

- Q: 5mm cement fiber board how much money a square?

- Beijing here is about 20-40 per month, is not tax with the freight, do not know which area you want,

- Q: where can i buy national gypsum perma base cement board?

- Try cshopping /buy

- Q: Do the ceiling is good or good with gypsum board good

- Etter board and gypsum board of the scope of application 1, Eute board: ETA board commonly used for external wall panels, bathroom partitions, outdoor roof roof, external wall insulation board, interior decoration, smallpox, etc .; can also replace the use of gypsum board in the decoration used as a substrate. 2, gypsum board: If the wall brush white, then the general use of gypsum board! This material is very good putty, and the outer surface is more beautiful.

- Q: the durock cement board is 1/2 inch and the drywall is 5/8 of an inch...So the shower wall is about an 1/8 of an inch recessed intothe wall. What can I do to fix the situation without redoing anymore walls. If I butt up the bullnose tile against the drywall about half of the tile's thickness sticks out...actually looks ok. I don't know if i should try to make a gradient from the drywall to the tile. There are also some gap between the two types of boards.....fill it with mortar?

- O.K. in this situation I will usually float this area , in other words the same way u float sheetrock , but I use mastic instead of gypsum compound.

- Q: what is the current price of Firbre cement board and where can it be found?

- I bought some 3ft x 5 ft sheets a long time ago for $15 dollars a piece. I'm sure it'll be more than that now. Home Depot has it.

- Q: What is the best fixation screw in the cement board?

- 1, the requirements of the construction of the ground and items to be clean without water. 2, the requirements of the ground have a certain degree of flatness, uneven or extremely rough parts of the application of cement mortar and other materials leveling. 3, grass-roots must remove the floating ash, oil, wax, so as not to affect the degree of adhesion. 4, paste the bolt after 5 to 15 minutes do not move to correct.

- Q: I'm going to apply cement board over water proof sheet rock,anything special i need to do other than screw it

- the cement board will be more effective and last years longer if it is attached directly to the wall studs instead of laid in over sheetrock .... even the water resistant greenboard has a shortened life in overly wet locations

Send your message to us

Fiber Cement Boards For Interior Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords