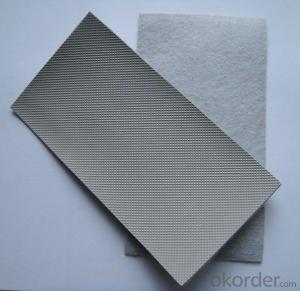

Fabric Compound PVC Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification

name:High Quality PVC Waterproofing membrane

brand:Wanbao

width:2.05m

thickness: 1.2mm,,1.5mm,,2.0mm

Waterproof material compound PVC waterproof membrane

1. Good c ombination of high elasticity and tensile strength.

2. Fine resistance to stactic electricity

3. Excellent resistance to ageing and weathering

4. Durable: If the pvc membranes used on exposed surfaces,the effective age can be more than 20 years.If the pvc membranes used on no-exposed surface, it can reach 50 years.

5. Fine flexibility at low temperaure, adaptable to cold conditions.

6. Root-resistance: The pvc membranes can be used on planting roofs.

7. Fine puncture resistance, joint peel srength and joint shear strength

8. Fine UV-resitance, no pollution to environment

9. Easily welding, installing, secure

10. Easy treaments to the delicate parts of corners and edges

11. Convenient maitance with low cost.

Product usage

Different kinds of Pvc waterproof membrane can variously be used to the roof building, underground building,tunnel,dam,pool,sewage treatment works,garbage disposal facilities.It also can be suitable to any requirement of all kinds of technological practice&different grade of roof waterproof and underground constructions waterproof.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: How does a waterproofing membrane adhere to a variety of surfaces?

- A waterproofing membrane adheres to a variety of surfaces by utilizing a strong adhesive backing or by being applied with a suitable adhesive. This allows it to bond effectively to different materials such as concrete, wood, metal, or even existing waterproofing layers. Additionally, some membranes may also have self-adhesive properties that eliminate the need for an external adhesive.

- Q: Can a waterproofing membrane be used for modular buildings or container homes?

- Yes, a waterproofing membrane can be used for modular buildings or container homes. It provides a protective layer against moisture, preventing water damage and enhancing the durability of the structure.

- Q: Can a waterproofing membrane be applied on top of existing roofing systems?

- Yes, a waterproofing membrane can be applied on top of existing roofing systems. This is a common practice in the roofing industry to enhance the waterproofing capabilities of an existing roof. The application of a waterproofing membrane involves the installation of a layer of material that is designed to prevent water infiltration. This membrane can be made of various materials such as asphalt, rubber, or synthetic materials. Before applying the waterproofing membrane, it is important to assess the condition of the existing roofing system. Any damage or defects should be repaired to ensure a solid foundation for the membrane. Additionally, the surface should be thoroughly cleaned and prepared to ensure proper adhesion of the membrane. Once the surface is ready, the waterproofing membrane can be applied using various methods such as hot-mopping, torching, or adhesive application. The membrane is typically installed in multiple layers to provide additional protection against water penetration. Applying a waterproofing membrane on top of an existing roofing system can provide several benefits. It can extend the lifespan of the roof by preventing water damage and leaks. It can also improve the energy efficiency of the building by reducing heat transfer and minimizing air leakage. Additionally, it can enhance the overall waterproofing capabilities of the roof, protecting the underlying structure from moisture-related issues. It is important to consult with a professional roofing contractor to determine the most suitable waterproofing membrane and installation method for your specific roofing system. They will be able to assess the condition of the existing roof and recommend the best course of action to ensure a successful application of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on below-grade foundations?

- Yes, a waterproofing membrane can be used on below-grade foundations. Waterproofing membranes are commonly used to prevent water infiltration and protect the foundation from moisture damage in below-grade applications.

- Q: Does a waterproofing membrane require any specific cleaning methods?

- Yes, a waterproofing membrane does require specific cleaning methods. It is important to clean the membrane regularly to maintain its effectiveness and longevity. The specific cleaning methods will depend on the type of waterproofing membrane being used, as different materials may have different cleaning requirements. In general, it is recommended to use gentle cleaning solutions and tools, such as a soft brush and mild detergent, to clean the membrane. It is important to avoid using harsh chemicals or abrasive materials that could damage the membrane. Additionally, regular inspection of the membrane for any signs of damage or debris accumulation is essential, as addressing these issues promptly can help prevent further damage and ensure the membrane continues to provide effective waterproofing. Consulting the manufacturer's guidelines and recommendations for cleaning and maintenance is highly recommended to ensure proper care of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for potable water tanks?

- Using a waterproofing membrane for potable water tanks is not recommended. Although a waterproofing membrane is effective in preventing water penetration and protecting surfaces from moisture damage, it is not suitable for guaranteeing the safety and purity of potable water. To ensure the safety of the water, materials specifically designed and approved for water storage, such as food-grade coatings or liners, should be used for potable water tanks. These materials are formulated to prevent any leaching or contamination of the water, thus ensuring its suitability for consumption. Hence, it is crucial to adhere to industry standards and regulations and utilize appropriate materials when constructing potable water tanks.

- Q: Can a waterproofing membrane be used for swimming pools and water features?

- Swimming pools and water features can benefit from the utilization of a waterproofing membrane. These specialized membranes serve the purpose of creating a barrier that effectively prevents water from permeating surfaces. They have proven to be highly valuable in a variety of applications, such as swimming pools and water features, where their primary objective is to confine water within the designated area. These membranes are typically crafted from materials that possess water-resistant properties, enabling them to withstand continuous exposure to moisture without incurring damage. Furthermore, their flexibility allows for convenient installation and adaptation to fit pools and water features of varying shapes and sizes. In summary, the implementation of a waterproofing membrane is an efficient and dependable method of guaranteeing the durability and longevity of swimming pools and water features.

- Q: Can waterproofing membranes be used on concrete fountains?

- Yes, waterproofing membranes can be used on concrete fountains. These membranes are designed to provide a protective barrier against water penetration, which is essential for preserving the structural integrity and preventing water damage in concrete fountains.

- Q: Can a waterproofing membrane be used on elevator pits?

- Yes, a waterproofing membrane can be used on elevator pits. Elevator pits are vulnerable to water damage due to their location below ground level and the potential for water infiltration. Installing a waterproofing membrane in the elevator pit can help protect the structure from water damage and prevent issues such as corrosion, mold growth, and deterioration. The membrane acts as a barrier, preventing water from seeping into the pit and causing damage to the elevator equipment or the surrounding structure. It is important to select a waterproofing membrane specifically designed for below-grade applications and to ensure proper installation to achieve effective waterproofing in elevator pits.

- Q: Can a waterproofing membrane be used for soundproofing purposes?

- Yes, a waterproofing membrane can be used for soundproofing purposes to some extent. While its primary function is to prevent water penetration, it can also help to reduce sound transmission. Waterproofing membranes are typically made of materials that have good acoustic properties, such as rubber or a combination of rubber and asphalt. These materials can absorb and dampen sound waves, thereby reducing the amount of noise that passes through a wall or floor. However, it is important to note that the soundproofing effectiveness of a waterproofing membrane may not be as high as that of specialized soundproofing materials like acoustic panels or insulation. Therefore, if soundproofing is the main goal, it is recommended to consider using dedicated soundproofing solutions in addition to or instead of a waterproofing membrane.

Send your message to us

Fabric Compound PVC Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords