Extruded Aluminum Tubing Profiles - Aluminium D-Profile According to European Standards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium D-profile According to European Standards Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium D-profile According to European Standards:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

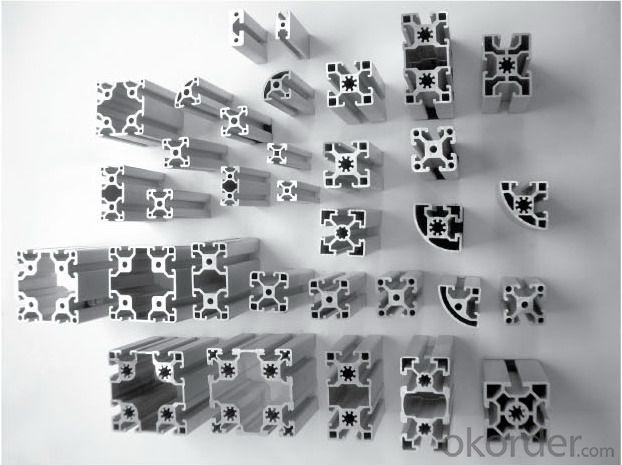

Images of the Aluminium D-profile According to European Standards:

Aluminium D-profile According to European Standards Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium D-profile According to European Standards:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks for various methods of producing aluminum profiles in a manner that is both efficient and cost-effective.

- <p>Efficient and cost-effective manufacturing of aluminum profiles can be achieved through several methods: 1) Using advanced extrusion technology, which is the primary method for shaping aluminum profiles, allows for high production rates and consistent quality. 2) Implementing automation in the production process to reduce labor costs and increase output. 3) Employing recycling techniques to use scrap aluminum, which lowers material costs and is environmentally friendly. 4) Optimizing the design of profiles to reduce material usage without compromising strength. 5) Utilizing energy-efficient equipment and processes to minimize energy consumption. 6) Regular maintenance and upgrading of machinery to ensure operational efficiency and reduce downtime. 7) Implementing just-in-time inventory management to minimize storage costs and reduce waste. 8) Continuous improvement through research and development to find new, more efficient methods of production.</p>

- Q: This question asks about the various dimensions and forms of aluminum profiles that are typically utilized in the construction of building frames.

- <p>Aluminum profiles used in building frames come in a variety of sizes and shapes to meet different structural requirements. Common profiles include rectangular tubes, square tubes, angles (L-profiles), channels, and tees. Sizes range from small (e.g., 10x10mm to 30x30mm) to large (e.g., 100x100mm to 200x200mm), with thicknesses varying from 1mm to 6mm or more. Shapes are tailored to specific applications; for example, I-beams and H-beams are used for their high strength-to-weight ratio. These profiles are chosen based on load-bearing needs, aesthetic preferences, and construction techniques.</p>

- Q: What are the aluminum profile markets in Cangzhou, Renqiu?

- Aluminum market, located in Renqiu city in Yi Zhen Zhang Liu Zhuang industrial area, if you find a direct about Liu Zhuang industrial zone can be. Known as the North's largest aluminum production base, I look not so good

- Q: Can aluminum profiles be bent or shaped?

- Aluminum profiles possess the capability of being bent or shaped in various ways. As a metal, aluminum is incredibly versatile and pliable, enabling it to effortlessly adopt numerous shapes and configurations. The procedure of bending or shaping aluminum profiles entails the application of heat and force to the metal, allowing it to be manipulated to one's desired form. This adaptability renders aluminum profiles exceptionally suitable for a wide array of industries, including construction, automotive, and aerospace, which demand materials that are both lightweight and durable. Moreover, aluminum profiles can also undergo extrusion, a process involving the metal being pushed through a die to create a specific shape or cross-section. All in all, the capacity to bend and shape aluminum profiles establishes them as a highly favored choice across various industries.

- Q: Are aluminum profiles suitable for material handling equipment?

- Yes, aluminum profiles are suitable for material handling equipment. Aluminum profiles offer several advantages that make them an ideal choice for material handling applications. Firstly, aluminum is lightweight yet strong, which makes it easier to handle and transport materials. This is especially beneficial for equipment that needs to be maneuvered or transported frequently. Secondly, aluminum profiles have excellent corrosion resistance properties, making them suitable for both indoor and outdoor material handling applications. This durability ensures that the equipment can withstand harsh environments and maintain its structural integrity over time. Additionally, aluminum profiles can be easily customized and assembled to create various types of material handling equipment, such as carts, conveyors, and shelving systems. The versatility of aluminum profiles allows for flexibility in design and adaptability to different material handling requirements. Furthermore, aluminum is a sustainable material as it is 100% recyclable. Choosing aluminum profiles for material handling equipment aligns with environmentally friendly practices and reduces the carbon footprint. In summary, aluminum profiles are indeed suitable for material handling equipment due to their lightweight yet strong nature, corrosion resistance, versatility in design, and sustainability.

- Q: This question asks for methods to protect aluminum profiles from damage during the installation process.

- <p>To prevent damage to aluminum profiles during installation, follow these guidelines: Use protective gloves and tools to avoid scratching the surface. Handle the profiles gently to prevent bending or denting. Ensure the work area is clean and free of debris that could damage the profiles. Apply protective films or tapes to vulnerable areas if necessary. Use the correct tools for cutting and drilling to avoid damaging the profile edges. Keep the profiles dry and away from corrosive substances. Always follow the manufacturer's guidelines for installation to ensure proper handling and protection of the aluminum profiles.</p>

- Q: What are the anti-static properties of aluminum profiles?

- The anti-static properties of aluminum profiles refer to their ability to prevent or dissipate static electricity buildup. Aluminum is a conductive material, allowing it to quickly discharge any static electricity that may accumulate on its surface. This property helps to prevent the buildup of electrostatic charges, which can be harmful to electronic components or cause problems in sensitive environments such as cleanrooms or manufacturing facilities.

- Q: This question asks whether aluminum profiles can be recycled and if so, the process involved in recycling them.

- <p>Yes, aluminum profiles can be recycled. The recycling process typically involves collection, sorting, and shredding the aluminum profiles. After shredding, the material is melted in a furnace, which separates impurities and leaves behind pure aluminum. This molten aluminum can then be cast into new profiles or other products. The recycling of aluminum is energy-efficient and environmentally friendly, as it requires only 5% of the energy needed to produce aluminum from raw materials. This makes aluminum recycling a sustainable practice that helps conserve resources and reduce waste.</p>

- Q: Are aluminum profiles suitable for playground equipment?

- Yes, aluminum profiles are suitable for playground equipment. Aluminum is a lightweight, durable, and corrosion-resistant material, making it ideal for use in playground equipment. It provides stability and strength while also being easy to work with and maintain. Additionally, aluminum profiles can be shaped into various forms, allowing for creative and innovative playground designs.

- Q: Can aluminum profiles be used in the construction of playground equipment?

- Yes, aluminum profiles can be used in the construction of playground equipment. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for playground structures. It is also easy to shape and customize, allowing for the creation of various designs and structures. Additionally, aluminum profiles can be coated or painted to enhance aesthetics and protect against weathering. Overall, aluminum profiles offer several advantages for playground equipment construction.

Send your message to us

Extruded Aluminum Tubing Profiles - Aluminium D-Profile According to European Standards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords