Aluminum Extrusion Profiles F Channel 8080 for Equipment Framework Aluminum Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

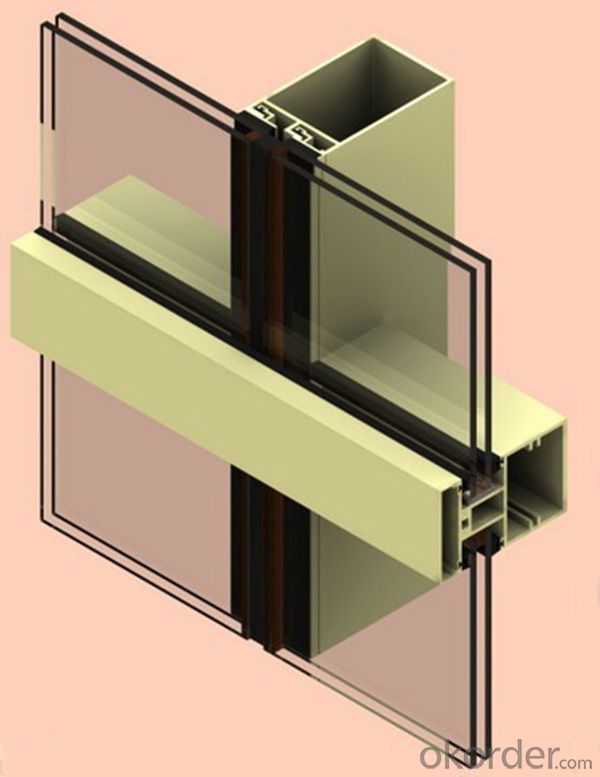

5. Image of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

6. Package and shipping of Extruded Aluminium 8080 for Equipment Framework Aluminum Profiles

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: What are the regular colors of aluminum profiles?

- The main process is:(1) surface pretreatment: chemical or physical methods are used to clean the surface of the profile and expose the pure matrix to obtain a complete and compact artificial oxide film. The mirror or non light (Ya Guang) surface can also be obtained by mechanical means.(2) anodizing: the surface of the pre processed profiles, in a certain process conditions, the substrate surface anodic oxidation, resulting in a dense, porous, strong adsorption of AL203 film.(3) sealing: the pore space of the porous oxide film produced by anodic oxidation is closed, so that the oxidation film is anti pollution, and the corrosion resistance and wear resistance are enhanced. The film is colorless and transparent, with strong adsorption before sealing film, adsorption and deposition of metal salts in some membrane hole, can make the profile appearance character (silver) show many colors, except such as: black, bronze, golden color and stainless steel etc..

- Q: What are the surface finishes available for aluminum profiles?

- Aluminum profiles offer a range of surface finishes, each with distinct aesthetics and properties. The options for surface finishes include: 1. Mill Finish: This is the standard finish straight from the mill, without any additional treatment. It has a raw look with visible manufacturing marks and is typically used for structural purposes where appearance is not important. 2. Anodized Finish: This finish involves an electrochemical process that forms a protective oxide layer on the aluminum surface, enhancing corrosion resistance and durability. Anodized finishes come in different colors and can have a glossy or matte appearance, making them popular for decorative applications. 3. Powder Coating: This finish involves applying dry powder to the aluminum surface and then curing it in an oven. It offers excellent durability, corrosion resistance, and a wide range of color options. It can also provide different textures, including smooth, matte, or textured, allowing for customization based on specific design needs. 4. Brushed Finish: Achieved by brushing the aluminum surface with abrasive materials, this finish creates fine lines for a brushed appearance. It is often used to add a decorative touch to aluminum profiles and can provide a sleek and modern look. 5. Polished Finish: Polishing entails using abrasive materials to create a smooth and shiny surface on the aluminum. This finish can range from high gloss, mirror-like appearance to a satin finish. It is commonly used in architectural applications where a reflective and visually appealing surface is desired. 6. Wood Grain Finish: This finish involves applying a special coating to the aluminum surface, imitating the look of wood grain. It provides a natural and warm appearance, making it suitable for applications where a wood-like aesthetic is desired without the maintenance requirements of real wood. These examples showcase the variety of surface finishes available for aluminum profiles. The selection of a finish depends on the intended use, desired appearance, and specific requirements such as corrosion resistance, durability, and ease of maintenance.

- Q: This question asks for an overview of the various types of aluminum profiles that are typically utilized in construction projects.

- <p>Aluminum profiles used in construction come in various types, each serving specific purposes. Common types include: 1. Extruded Profiles: These are the most common, created by forcing aluminum through a die to achieve desired shapes. 2. Structural Profiles: Used for structural integrity in buildings, such as beams and columns. 3. Fa莽ade Profiles: Specifically designed for the exterior cladding of buildings. 4. Window and Door Profiles: For frame construction in windows and doors. 5. Fastening Profiles: Used for joining and fixing other aluminum components. 6. Special Profiles: Custom-made for unique applications. 7. Decorative Profiles: For aesthetic purposes, enhancing the appearance of structures. Each type has specific properties and is chosen based on the structural requirements and design considerations of the construction project.</p>

- Q: This question asks for guidelines to ensure the proper and safe installation of aluminum profiles.

- <p>To ensure the correct and safe installation of aluminum profiles, follow these steps: 1. Use high-quality aluminum profiles that meet industry standards. 2. Prepare the surface by cleaning and leveling it. 3. Use appropriate tools like drills, screws, and cutting equipment. 4. Follow the manufacturer's guidelines for installation. 5. Ensure proper alignment and spacing of the profiles. 6. Secure the profiles with the right fasteners and adhesives. 7. Check for any sharp edges or protrusions after installation. 8. Regularly inspect and maintain the profiles to prevent any damage or wear. By adhering to these steps, you can ensure a safe and secure installation of aluminum profiles.</p>

- Q: Are aluminum profiles resistant to mold or mildew?

- Yes, aluminum profiles are resistant to mold or mildew.

- Q: What are the different surface engraving or etching techniques for aluminum profiles?

- There are several surface engraving or etching techniques available for aluminum profiles, each offering unique benefits and results. Some of the commonly used techniques include: 1. Chemical Etching: This process involves the use of chemicals to selectively remove the top layer of the aluminum profile. It allows for precise and intricate designs to be etched onto the surface, making it suitable for decorative purposes. 2. Laser Engraving: Laser engraving utilizes a high-powered laser beam to vaporize the aluminum surface, creating a permanent etching. This technique offers excellent precision, allowing for detailed designs and logos to be engraved onto the profile. 3. Mechanical Engraving: Mechanical engraving involves the use of rotary cutters or diamond-tipped tools to physically engrave the surface of the aluminum profile. This technique is commonly used for industrial applications, such as marking product codes or serial numbers. 4. Electrochemical Etching: This technique uses an electric current and an electrolyte solution to etch the aluminum surface. It is commonly employed for creating durable and legible markings, such as product labels or identification codes. 5. Sandblasting: Sandblasting involves directing a stream of abrasive particles at high speed onto the aluminum surface. This process removes the top layer of the material, leaving a textured or frosted appearance. Sandblasting is often used for decorative purposes or to create a matte finish. 6. Acid Etching: Acid etching utilizes an acid solution to selectively remove the top layer of the aluminum surface. This technique is commonly used for creating a matte or satin finish, as well as for creating patterns or textures on the profile. These engraving and etching techniques offer a wide range of options for aluminum profiles, allowing for customization, branding, or functional purposes. The choice of technique depends on factors such as the desired design, level of detail, durability requirements, and the intended application of the aluminum profile.

- Q: Can aluminum profiles be used for curtain walls?

- Yes, aluminum profiles can be used for curtain walls. Aluminum is a popular material choice for curtain wall systems due to its lightweight, durability, and corrosion resistance. It offers flexibility in design, ease of installation, and can accommodate large glass panels, making it an ideal choice for modern architectural designs.

- Q: This question asks about the typical applications of aluminum profiles within the field of architectural design.

- <p>Aluminum profiles are commonly used in building design for various structural and aesthetic purposes. They are utilized in curtain walls, window frames, and door systems for their strength and lightweight properties. Additionally, aluminum profiles are employed in the construction of balconies, handrails, and sunshades due to their durability and resistance to corrosion. They are also used in interior design for creating partition walls, ceiling systems, and decorative elements. The versatility of aluminum profiles allows them to be easily adapted to different architectural styles and requirements, making them a popular choice in modern construction.</p>

- Q: Can aluminum profiles be used for soundproofing?

- Yes, aluminum profiles can be used for soundproofing. Aluminum profiles can be combined with soundproofing materials such as acoustic foam or rubber gaskets to create an effective sound barrier. Additionally, aluminum profiles have the advantage of being lightweight and easy to install, making them a practical choice for soundproofing purposes.

- Q: Are there any limitations or drawbacks of using aluminum profiles?

- Yes, there are limitations and drawbacks to using aluminum profiles. One limitation is that aluminum is not as strong as other metals like steel, so it may not be suitable for applications that require high strength or load-bearing capacities. Additionally, aluminum profiles can be more expensive compared to other materials. They can also be prone to corrosion if not properly protected or coated. Finally, aluminum profiles may have limited design options compared to other materials, potentially restricting the range of shapes and sizes that can be achieved.

Send your message to us

Aluminum Extrusion Profiles F Channel 8080 for Equipment Framework Aluminum Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords