Aluminum Extrusion Profiles F Channel Highly Functional Easy Assembly T-Slot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Extrusion Profile Highly Functional Easy Assembly T-Slot

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Extrusion Profile Highly Functional Easy Assembly T-Slot

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Extrusion Profile Highly Functional Easy Assembly T-Slot

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

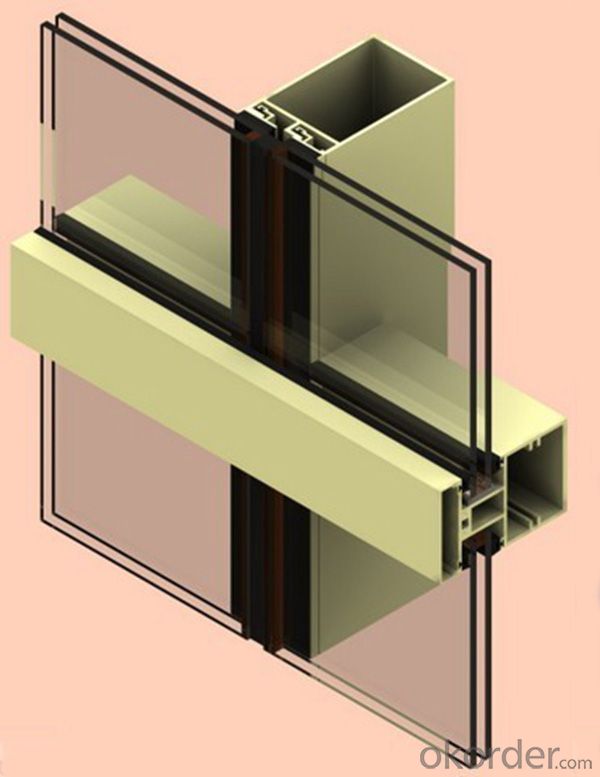

5. Image of Aluminum Extrusion Profile Highly Functional Easy Assembly T-Slot

6. Package and shipping of Aluminum Extrusion Profile Highly Functional Easy Assembly T-Slot

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Can aluminum profiles cross Luo? Why is the appearance of an aluminum profile component of a Japanese original machine extremely close to that of Luo Luo? Why? Why?

- Luoyang City days Feng Aluminum Co. Ltd. was founded in 2007, is located in the Luoyang world cultural heritage Longmen Grottoes in southern Yichuan County Bai Yuan Xiang Xia Bao Industrial Park, east of Beijing Guangzhou Jiaozhitielu, West luoluan fast channel, north of Los, Zhengshao, Lianhuo expressway entrance, the position is superior, the transportation is convenient, is one of the the Central Plains aluminum production largest manufacturers.The company has a total investment of RMB 600 million yuan, covering an area of 96000 square meters, and has 96 employees, including 18 technicians and management personnel, and the finance is included in the microcomputer managementThe company in Yichuan County, Xin'an County two national electrolytic aluminum production base, production of industrial aluminum profiles, civil building materials and design of electrophoresis aluminum, the annual output of 50 thousand tons, the construction in two phases, the first phase of the project investment of 600 million yuan, the company has invested more than 2000 yuan, at present, and some office building the factory, the warehouse has been built and put into use, the project construction procedures have been improved.

- Q: What are the recycling capabilities of aluminum profiles?

- Due to its inherent properties, aluminum profiles possess excellent recycling capabilities. The material itself is highly recyclable, meaning it can be reused multiple times without any loss in quality or properties. When recycling aluminum profiles, the process involves melting them down to eliminate impurities and coatings. The resulting aluminum can then be shaped into new profiles or other aluminum products. Recycling aluminum profiles offers a key advantage in terms of energy savings compared to producing new aluminum. The energy required for recycling aluminum is only about 5% of what is needed for extracting and refining primary aluminum from bauxite ore. This energy efficiency not only reduces environmental impact but also leads to cost savings in the production process. Moreover, recycling aluminum profiles helps conserve natural resources by reducing the need for mining and extraction of bauxite. By reusing existing aluminum, we can preserve valuable resources and minimize the ecological footprint associated with acquiring and transporting raw materials. Furthermore, the high scrap value of aluminum profiles makes them highly valuable in the recycling industry. The well-established scrap aluminum market facilitates the collection and processing of discarded profiles. This serves as an incentive for individuals and businesses to recycle their aluminum waste, as they have the opportunity to earn money by selling it to scrap dealers or recycling centers. In conclusion, the recycling capabilities of aluminum profiles are remarkable, making them a sustainable choice for various industries. By promoting the recycling of aluminum profiles, we can reduce energy consumption, mitigate resource depletion, and contribute to a more environmentally friendly and economically viable future.

- Q: This question asks if aluminum profiles can be utilized for constructing interior partitions or ceilings.

- <p>Yes, aluminum profiles are commonly used for interior partitions and ceilings due to their strength, durability, and lightweight properties. They offer design flexibility, are easy to install, and can be used in conjunction with various materials like glass or fabric. Additionally, aluminum profiles are resistant to corrosion and require minimal maintenance, making them a popular choice for both residential and commercial applications.</p>

- Q: What are the regular colors of aluminum profiles?

- The main process is:(1) surface pretreatment: chemical or physical methods are used to clean the surface of the profile and expose the pure matrix to obtain a complete and compact artificial oxide film. The mirror or non light (Ya Guang) surface can also be obtained by mechanical means.(2) anodizing: the surface of the pre processed profiles, in a certain process conditions, the substrate surface anodic oxidation, resulting in a dense, porous, strong adsorption of AL203 film.(3) sealing: the pore space of the porous oxide film produced by anodic oxidation is closed, so that the oxidation film is anti pollution, and the corrosion resistance and wear resistance are enhanced. The film is colorless and transparent, with strong adsorption before sealing film, adsorption and deposition of metal salts in some membrane hole, can make the profile appearance character (silver) show many colors, except such as: black, bronze, golden color and stainless steel etc..

- Q: What are the different surface patterns available for aluminum profiles?

- Aluminum profiles offer a variety of surface patterns, each with unique advantages in terms of appearance and function. The options include: 1. Smooth: This basic pattern features a polished finish, providing a sleek and modern look suitable for applications where aesthetics matter. 2. Brushed: This pattern showcases fine lines or brush strokes in one direction, creating a textured, satin-like appearance popular in contemporary and industrial designs. 3. Anodized: Anodizing is an electrochemical process that results in a durable, corrosion-resistant surface. It can be tailored to achieve different colors and finishes, such as matte, glossy, or metallic. 4. Powder-coated: This technique involves applying dry powder to the aluminum surface, which is then heated to create a smooth and long-lasting finish. It allows for a wide array of colors and textures, including matte, glossy, and textured options. 5. Wood grain: Specialized printing techniques can mimic the look of wood on aluminum profiles. This pattern offers the warm and natural appearance of wood while retaining the durability and low maintenance of aluminum. 6. Textured: Aluminum profiles can also feature a range of textures, from fine sand-like patterns to more pronounced embossed or hammered looks. Textured surfaces not only enhance visual appeal but also provide improved grip and slip resistance. These examples represent just a few of the available surface patterns for aluminum profiles. The choice of pattern depends on specific application requirements, desired aesthetics, and functional needs.

- Q: Are there any specific requirements for transporting and storing aluminum profiles?

- Yes, there are specific requirements for transporting and storing aluminum profiles. Aluminum profiles should be handled with care to prevent any damage or deformation. During transportation, they should be properly secured to avoid shifting or falling. It is recommended to use protective packaging and cushioning materials to prevent scratches or dents. When storing aluminum profiles, they should be kept in a clean and dry area to prevent corrosion. It is advisable to stack them horizontally or on racks to avoid bending or warping. Additionally, they should be stored away from direct sunlight and extreme temperatures.

- Q: What kind of self tapping screw can attack aluminum profile?

- General aluminum, iron, stainless steel can attack ah!

- Q: How do aluminum profiles contribute to the reduction of noise pollution?

- Aluminum profiles contribute to the reduction of noise pollution in several ways. Firstly, aluminum is a lightweight material that can be used to construct windows and doors with excellent sound insulation properties. These profiles can effectively block and absorb sound waves, preventing outside noise from entering indoor spaces and vice versa. Moreover, aluminum profiles are highly durable and can maintain their structural integrity over time. This durability ensures that the sound insulation properties of the profiles remain effective for an extended period. Unlike other materials, aluminum does not warp or degrade easily, allowing it to consistently provide a barrier against noise pollution. Additionally, aluminum profiles can be designed with special features to enhance their noise reduction capabilities. For instance, manufacturers can incorporate rubber or foam seals into the profiles, which further minimize sound transmission by creating an airtight seal when the windows or doors are closed. These seals effectively block out external noise, creating a quieter and more peaceful indoor environment. Furthermore, aluminum profiles can be customized to fit specific requirements and noise reduction needs. They can be designed with multiple layers of glass, each with different thicknesses and acoustic properties, to provide even higher levels of sound insulation. This customization allows for the creation of tailored solutions to address different levels of noise pollution, making aluminum profiles a versatile option for noise reduction. In summary, aluminum profiles contribute to the reduction of noise pollution through their lightweight yet durable construction, sound insulation properties, and customization options. By blocking and absorbing sound waves, these profiles create a quieter indoor environment, enhancing the overall comfort and quality of life for individuals in both residential and commercial spaces.

- Q: What are the mechanical properties of aluminum profiles?

- The mechanical properties of aluminum profiles include high strength-to-weight ratio, excellent corrosion resistance, good thermal and electrical conductivity, and the ability to be easily fabricated and welded.

- Q: This question seeks advice on making the aluminum profile production process eco-friendly.

- <p>To ensure an environmentally friendly production process for aluminum profiles, consider the following: Use recycled aluminum whenever possible to reduce the energy needed for production. Implement energy-efficient technologies and machinery in the production line. Minimize waste by optimizing production processes and recycling any aluminum scraps generated. Employ water-saving measures and treat any wastewater before discharge. Reduce emissions by using low-emission fuels and investing in pollution control equipment. Regularly monitor and assess the environmental impact of your operations and strive for continuous improvement.</p>

Send your message to us

Aluminum Extrusion Profiles F Channel Highly Functional Easy Assembly T-Slot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords