Extreme Green Aluminum Sheets - Mill Finish Aluminum Flat Plate 5 Series Alloy for Marine Boat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Flat Plate 5 Series Alloy for Marine Boat

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Flat Plate 5 Series Alloy for Marine Boat

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Mill Finish Aluminium Flat Plate 5 Series Alloy for Marine Boat

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

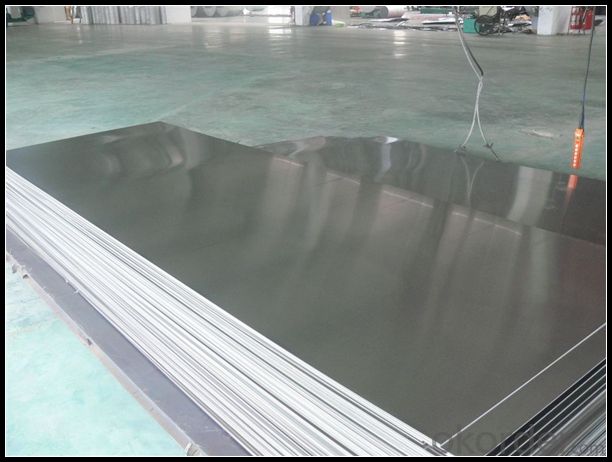

5. Image of Mill Finish Aluminium Flat Plate 5 Series Alloy for Marine Boat

6. Package and shipping of Mill Finish Aluminium Flat Plate 5 Series Alloy for Marine Boat

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets affected by UV radiation or sunlight exposure?

- Yes, aluminum sheets are affected by UV radiation and sunlight exposure. Over time, exposure to UV radiation and sunlight can cause the aluminum sheets to oxidize, resulting in a dull and discolored appearance. Additionally, prolonged exposure to UV rays can weaken the material, making it more prone to cracking or breaking. To protect aluminum sheets from the damaging effects of UV radiation, it is recommended to apply a protective coating or use anodized aluminum, which has a more robust and durable surface.

- Q: Are aluminum sheets suitable for roofing systems?

- Yes, aluminum sheets are suitable for roofing systems. Aluminum is a popular choice for roofing due to its durability, lightweight nature, and resistance to corrosion. It is also fire resistant and can withstand extreme weather conditions such as high winds and heavy rain. Aluminum roofing sheets are long-lasting and require minimal maintenance, making them a cost-effective option in the long run. Additionally, aluminum is a highly reflective material, which can help in reducing energy costs by keeping buildings cooler in hot climates. Overall, aluminum sheets are a reliable and efficient choice for roofing systems.

- Q: Can aluminum sheet be used for signage?

- Certainly! Aluminum sheet is a viable option for signage purposes. Its durability, versatility, and cost-effectiveness make it a popular choice among sign makers. Being a lightweight material, it is resistant to corrosion, making it suitable for both indoor and outdoor signage. With aluminum sheet, one can easily cut, shape, and form it into various sizes and designs, allowing for customizable signage options. Moreover, it is effortless to print or engrave upon, making it perfect for displaying text, graphics, and logos. Its sleek and professional appearance enhances its appeal for signage purposes. In conclusion, aluminum sheet is an excellent choice for signage due to its durability, versatility, and aesthetic qualities.

- Q: Remember the notorious Chevy Vega of the 1970's? As I recall,one the big problems with that car was that it was equipped with an aluminum block engine. The new Ford Mustangs arealso equipped with aluminum engines to reduce curb weightand improve fuel efficiency. Will they be prone to the sameproblems that the Vega had down the road? Are there othermanufacturers that have used aluminum engines with successrecently?

- Aluminum is the most easily repaired material used in engines and can be readily welded. The problem is access and/or does the repair threaten to go into a machined area such as a cylinder wall? If I was really short of cash I might even try filling a groove with jb weld. A crack goes deeper though and requires a more thorough fix. Are you sure this is an aluminum block? Iron is much harder to fix, probably can't be done without spending more that a replacement engine would cost. If it is aluminum, I would have to towed out of there and find myself another garage.

- Q: Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring. Aluminum sheet is primarily used for structural and decorative purposes due to its lightweight and corrosion-resistant properties. However, aluminum wire, which has different characteristics and is specifically manufactured for electrical applications, can be used for electrical wiring. Aluminum wire was commonly used in the past, but due to concerns about its conductivity, durability, and potential fire hazards, it has been largely replaced by copper wire in residential and commercial electrical installations. Copper wire is preferred for its superior conductivity and lower risk of developing loose connections or overheating.

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: Can aluminum sheets be used for modular construction?

- Absolutely, modular construction can utilize aluminum sheets. Aluminum proves to be an adaptable and lightweight substance that presents numerous advantages for modular construction undertakings. Its resilience, resistance to corrosion, and impressive strength-to-weight ratio render it appropriate for a wide range of structural applications. The malleability of aluminum sheets permits them to be effortlessly fabricated and molded into various forms and dimensions, enabling flexibility in both design and construction. Furthermore, aluminum's recyclability positions it as an environmentally conscious selection for sustainable construction practices. All things considered, aluminum sheets stand as a feasible choice for modular construction given their robustness, durability, and versatility.

- Q: I have a set of Chrome Aluminum rims, and two of them have scratches on them. So instead of buying new ones, is it possible to paint them. I was thinking black.

- You have either chrome or aluminum, not the same, 2 different rims. You cannot paint either, paint eill not stick to chrome or aluminum, it will just flake off.

- Q: What are the different methods for engraving aluminum sheets?

- There are several methods for engraving aluminum sheets, including laser engraving, rotary engraving, chemical etching, and mechanical engraving. Each method offers unique benefits and can produce high-quality results depending on the desired outcome and specific requirements.

- Q: a dream I had where the carbon element was extracted from aluminum and ploished it became transparent, it was bendable and you could puncher it with out breaking it ?

- Aluminium is an element! Elements are pure substances, therefore aluminium doesn't contain any carbon. What do you mean?

Send your message to us

Extreme Green Aluminum Sheets - Mill Finish Aluminum Flat Plate 5 Series Alloy for Marine Boat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords