Galvanized/Aluzinc Steel Sheet or Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

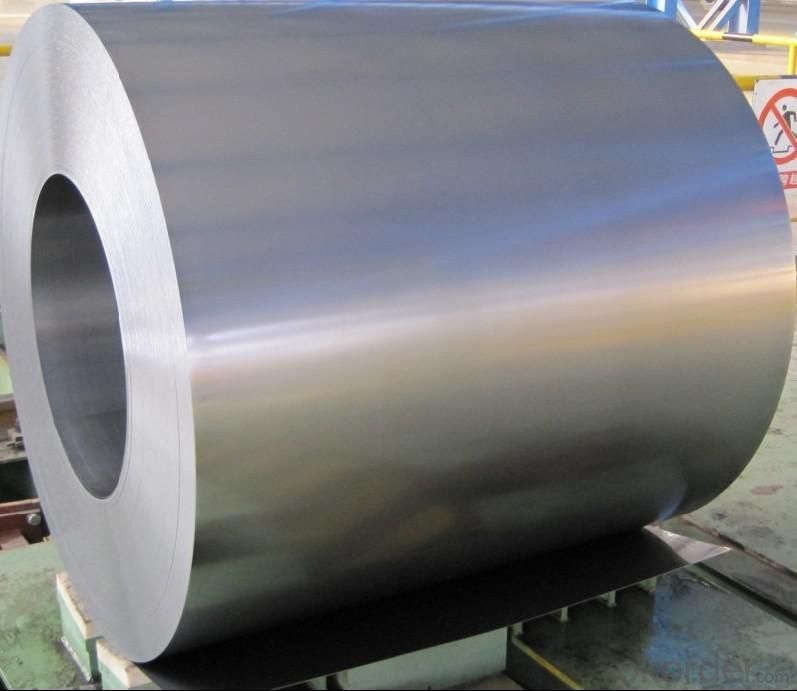

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

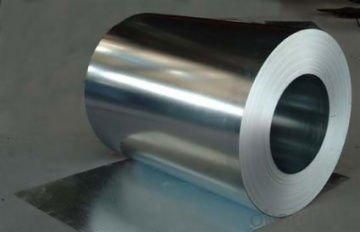

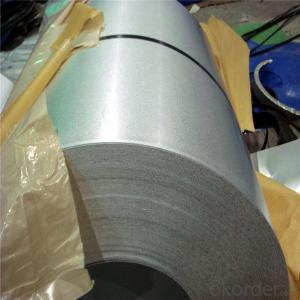

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

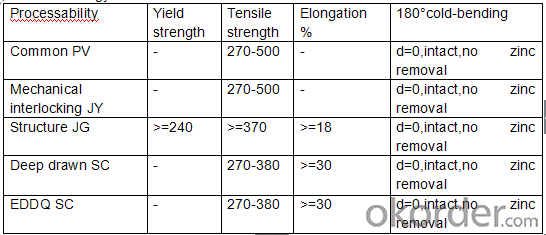

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets be used for automotive body reinforcements?

- Yes, steel sheets can be used for automotive body reinforcements. Steel is commonly used in the automotive industry for its high strength-to-weight ratio, durability, and ability to withstand impact and collision forces. Steel sheets can be shaped, molded, and welded to reinforce the body structure of vehicles, providing enhanced safety and structural integrity.

- Q: What are the different packaging options for steel sheets?

- Some common packaging options for steel sheets include bundles, coils, crates, and pallets. Bundles are typically used for smaller quantities and consist of multiple sheets bound together with metal or plastic straps. Coils are used for long sheets and are tightly wound into cylindrical shapes. Crates are wooden or metal structures that provide protection during transportation and storage. Pallets are flat structures on which steel sheets are stacked and secured using straps or stretch wrap. These packaging options ensure safe handling and transportation of steel sheets while preventing damage or deformation.

- Q: Can steel sheets be used for heat exchangers or boilers?

- Yes, steel sheets can be used for heat exchangers or boilers. Steel is a commonly used material for these applications due to its excellent thermal conductivity, high strength, and resistance to corrosion at high temperatures.

- Q: Are the steel sheets suitable for automotive applications?

- Yes, steel sheets are commonly used in automotive applications due to their high strength, durability, and formability. They provide structural support, enhance crash safety, and can be easily shaped into various automotive components, making them suitable for the automotive industry.

- Q: How are steel sheets protected during shipping?

- To guarantee the secure delivery of steel sheets, numerous measures are taken to protect them during shipping. One commonly used technique involves using packaging materials like cardboard or wooden crates, specifically designed to securely hold the steel sheets in place and reduce the risk of movement or potential damage during transit. Furthermore, steel sheets may also be shielded from moisture, dust, and other environmental factors by applying a protective coating or wrap. This can take the form of a thin layer of oil, wax, or a specialized rust inhibitor, acting as a barrier against corrosion. To enhance protection even further, steel sheets are often stacked and fastened with strapping or banding materials. These measures ensure that the sheets remain in a fixed position and do not shift during transportation, preventing any potential impact or friction that could cause damage. Additionally, shipping companies implement special handling procedures to minimize the risk of harm. This involves utilizing equipment such as forklifts or cranes to carefully load and unload the steel sheets, avoiding any rough handling or accidental drops that could result in dents or bends. In conclusion, a combination of appropriate packaging, protective coatings, secure strapping, and careful handling guarantees the adequate protection of steel sheets during shipping. This comprehensive approach minimizes the possibility of any damage occurring and ensures that the sheets arrive in optimal condition at their intended destination.

- Q: Can steel sheets be recycled multiple times?

- Yes, steel sheets can be recycled multiple times. Steel is one of the most recycled materials in the world due to its durability and recyclability. When steel sheets reach the end of their useful life, they can be collected, melted down, and reprocessed into new steel products. This process can be repeated numerous times without compromising the quality of the steel. Recycling steel sheets not only conserves natural resources but also reduces energy consumption and greenhouse gas emissions associated with the production of new steel.

- Q: What is the average lead time for ordering steel sheets?

- The lead time for ordering steel sheets can vary due to different factors, including the supplier, required quantity, customization needs, and current market conditions. Typically, the lead time ranges from a few days to several weeks. If the supplier has the steel sheets in stock, the lead time can be as short as a few days or less, ensuring prompt order fulfillment. However, if the sheets need to be obtained from a specific mill or manufacturer, the lead time may be longer. This is particularly true for orders with custom specifications, such as specific dimensions, finishes, or steel grades. Other factors that impact lead time include the supplier's production capacity and workload, transportation and logistics considerations, and potential delays resulting from unexpected events like natural disasters or labor disputes. To obtain accurate lead time estimates, it is crucial to communicate with the supplier or manufacturer. They can provide specific information based on their production capabilities and current circumstances. Moreover, it is advisable to plan ahead and allow for some buffer time to accommodate potential delays or unforeseen challenges during the ordering process.

- Q: What are the different sheet metal welding techniques for steel sheets?

- Steel sheets can be joined using various sheet metal welding techniques. The most commonly used methods are as follows: 1. MIG welding, also known as Gas Metal Arc Welding (GMAW), involves the use of a continuous wire electrode to create an arc and join the steel sheets. This technique is versatile and efficient, suitable for both thin and thick sheets. 2. TIG welding, or Gas Tungsten Arc Welding (GTAW), utilizes a non-consumable tungsten electrode to create an arc and join the steel sheets. It produces high-quality welds with excellent control, making it ideal for thin or delicate sheet metal. 3. Resistance Spot Welding (RSW) involves applying pressure and passing a high electrical current through the steel sheets using two electrodes. This causes the sheets to fuse together swiftly and cost-effectively. It is commonly used in the automotive and manufacturing industries. 4. Laser Welding employs a high-energy laser beam to melt and join the steel sheets. The technique offers precise control, high welding speeds, and minimal heat input, making it suitable for thin and highly reflective materials. 5. Electron Beam Welding (EBW) utilizes a focused beam of high-velocity electrons to create a weld. It offers deep penetration and is often used for thick steel sheets or applications requiring high-quality welds. 6. Plasma Arc Welding (PAW) is similar to TIG welding but utilizes a plasma arc to create a weld. This technique provides higher welding speeds and can be used for both thick and thin steel sheets. The choice of welding technique depends on various factors such as the thickness of the steel sheets, desired weld quality, production volume, and available equipment. Each method has its own advantages and limitations.

- Q: Can steel sheets be used for mezzanine flooring?

- Indeed, mezzanine flooring can make use of steel sheets. Mezzanine flooring benefits from the numerous advantages provided by steel sheets, such as their strength, durability, and versatility. Steel sheets are capable of withstanding substantial loads and offer a dependable and stable solution for flooring needs. Moreover, they can be easily tailored to suit specific dimensions and requirements, making them adaptable for various mezzanine designs. Additionally, steel sheets exhibit resistance to fire, moisture, and pests, guaranteeing a flooring option that is long-lasting and requires minimal maintenance. In summary, due to their robustness, durability, and adaptability, steel sheets are a popular choice for mezzanine flooring.

- Q: Are the steel sheets suitable for shipbuilding?

- Yes, steel sheets are suitable for shipbuilding due to their high tensile strength, durability, and ability to withstand harsh marine environments.

Send your message to us

Galvanized/Aluzinc Steel Sheet or Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords