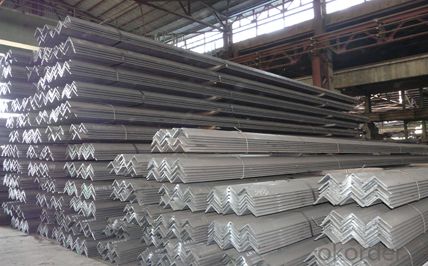

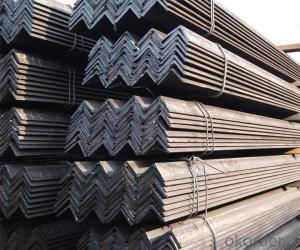

Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

1.Manufacturer

2. High quality, sincere service, fair price

3. Excellent Performance

Different Sizes of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

| StandardSectional Dimension mm | Weight kg/m | StandardSectional Dimension mm | Weight kg/m |

| 25*25*3 | 1.12 | 90*90*6 | 8.28 |

| 30*30*3 | 1.36 | 90*90*7 | 9.59 |

| 40*40*3 | 1.83 | 90*90*10 | 13.3 |

| 40*40*5 | 2.95 | 100*100*7 | 10.7 |

| 45*45*4 | 2.74 | 100*100*10 | 14.9 |

| 45*45*5 | 3.38 | 100*100*13 | 19.1 |

| 50*50*4 | 3.06 | 120*120*8 | 14.7 |

| 50*50*6 | 4.43 | 130*130*9 | 17.9 |

| 60*60*4 | 3.68 | 130*130*12 | 23.4 |

| 60*60*5 | 4.55 | 130*130*15 | 28.8 |

| 60*60*6 | 5.37 | 150*150*12 | 27.3 |

| 65*65*6 | 5.91 | 150*150*15 | 33.6 |

| 65*65*8 | 7.66 | 150*150*19 | 41.9 |

| 70*70*6 | 6.38 | 175*175*12 | 31.8 |

| 75*75*6 | 6.85 | 175*175*15 | 39.4 |

| 75*75*6 | 9.96 | 200*200*15 | 45.3 |

| 80*80*6 | 7.32 | 200*200*20 | 59.7 |

| 80*80*7 | 8.48 | 200*200*25 | 73.6 |

Product Specification of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

| Product | Equal Steel Angle Steel Galvanized SS400 Best Angle Steel |

| Product classification | Equal Angle Steel & Unequal Angle Steel |

| Production Technics | Hot rolled,cold-bend |

| Productivity | 300,000 Mt/Year |

| Main Material | SS400,Q235A,Q235B,Q345,Q345B,ASTM A36,S235JR,ST37,Stainless steel series,etc |

| Surface treatment | hot dip galvanised or cold dip galvanised |

| Specification | (20*20*2mm)-(200*200*25mm) |

| Theoretical weight per meter | =0.00785*(width+width-thickness)*thickness |

| Application | widely used in Power tower, communication tower, railway, highway, street lamp pole, marine parts, construction steel structure component, handling machinery ,Container frame , warehouse ,reaction tower,the substation ancillary facilities, light industry etc. |

| Length | 6m-12m as you require |

Applications of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

1. Pipe and Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

Advantages of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

We have both advanced production line, and advanced quality detecting, such as HLGER read-directlys

pectrum instrument, infrared CS analysis instrument, which can do ultrasonic test, crystal corrosion test and

metallographic test.

- Q: What are the common uses of unequal steel angles?

- Unequal steel angles are commonly used in construction, engineering, and fabrication projects. They are often used as structural supports, providing stability and strength in frameworks, buildings, and bridges. These angles are also used for creating bracing systems, reinforcing corner joints, and as components in machinery and equipment. Additionally, they are utilized in architectural designs for decorative purposes, adding aesthetic appeal to structures.

- Q: Can steel angles be used for manufacturing safety barriers?

- Indeed, safety barriers can be manufactured using steel angles. In construction projects, steel angles are frequently utilized owing to their robustness and longevity. Specifically for safety barriers, they offer a firm framework that can endure impacts and offer protection. By welding or bolting steel angles together, a solid and secure barrier can be created effortlessly. Furthermore, by galvanizing or coating steel angles with anti-corrosive substances, their lifespan and resistance against environmental factors can be enhanced. In summary, steel angles are an exceptional option for manufacturing safety barriers due to their strength, durability, and versatility.

- Q: What is the minimum thickness for a steel angle beam?

- The minimum thickness for a steel angle beam would depend on various factors, including the specific load requirements and design specifications. It is essential to consult engineering guidelines and structural design codes to determine the appropriate minimum thickness for a steel angle beam in a given application.

- Q: Can steel angles be used in railway or transportation infrastructure?

- Steel angles have the potential to be utilized in railway or transportation infrastructure. They are frequently employed in the building of bridges, tunnels, and railway tracks. These infrastructure components rely on steel angles for structural support and stability. The reputation of steel angles stems from their strength, durability, and versatility. They can be effortlessly fabricated and installed, which contributes to their popularity in transportation projects. Additionally, steel angles possess the ability to endure substantial loads and adverse weather conditions, rendering them suitable for railway and transportation purposes where safety and reliability are of utmost importance. In summary, steel angles offer a dependable and cost-effective solution for railway and transportation infrastructure needs.

- Q: How do you store steel angles?

- Steel angles have various storage options depending on space availability and quantity. Here are a few commonly used techniques: 1. Vertical Storage: To store steel angles vertically, they can be leaned against a wall or placed on a storage rack. This method works well for smaller quantities, allowing easy access to each angle. It is crucial to ensure stability and secure positioning to prevent accidents. 2. Horizontal Storage: For larger quantities, steel angles can be stored horizontally. This can be achieved by stacking them on a pallet or using a compartmentalized storage rack. When stacking, it is important to evenly distribute the weight and use spacers between angles to prevent deformation. 3. Bundled Storage: When dealing with a large number of steel angles, bundling them together can be a convenient storage method. This involves tying the angles with steel strapping or using banding equipment. Bundling helps maintain organization and prevents shifting or falling during storage or transportation. Regardless of the chosen storage method, the following points should be considered: - Provide a clean and dry storage area to prevent rust or corrosion. - Ensure proper ventilation to avoid moisture buildup. - Keep angles away from direct sunlight and extreme temperature changes. - Regularly inspect for damage or corrosion. - Use appropriate lifting equipment and follow safety guidelines when moving or stacking steel angles.

- Q: What are the different types of steel angles?

- A variety of steel angles exist, each serving specific purposes and applications. Here are some common types: 1. Equal angle: Utilized for structural support, bracing, and framing in construction, this angle boasts equal sides. 2. Unequal angle: Also known as L-shaped or unequal leg angle, it features unequal sides, with one side longer than the other. It finds use in building construction for creating corners, edges, and supports. 3. Stainless steel angle: Crafted from stainless steel, this angle offers exceptional resistance to corrosion. It is commonly employed in environments exposed to moisture or chemicals, such as marine settings or food processing facilities. 4. Galvanized angle: These steel angles are coated with a layer of zinc to safeguard against rust and corrosion. They are frequently utilized in outdoor and industrial settings where durability is crucial. 5. Slotted angle: Equipped with holes or slots along its length, this steel angle facilitates easy attachment and adjustment of components. It is commonly found in shelving systems, storage racks, and DIY projects. 6. Rolled steel angle: Manufactured by rolling steel into a specific shape, it results in a smooth and uniform surface. Rolled steel angles are often employed in manufacturing, machinery, and structural applications. 7. Structural angle: Designed to bear heavy loads and provide structural support, these steel angles are prevalent in building frames, bridges, and other infrastructure projects. These examples represent only a fraction of the diverse range of steel angles available. The selection of the appropriate angle depends on various project requirements, such as load capacity, corrosion resistance, and aesthetic considerations. Seeking advice from professionals or structural engineers can aid in determining the most suitable type of steel angle for a specific application.

- Q: What is the minimum thickness for a steel angle bracket?

- The minimum thickness for a steel angle bracket can vary depending on the specific application and load requirements. However, in general, a minimum thickness of 1/8 inch (3.18 mm) is often considered standard for most angle brackets.

- Q: Can steel angles be used for framing partitions and walls?

- Indeed, framing partitions and walls can be accomplished by utilizing steel angles. In construction, steel angles are extensively employed due to their robustness and longevity. A framework for partitions and walls can be established by employing steel angles, which offer structural reinforcement and stability. Steel angles possess adaptability, enabling them to be effortlessly cut and welded to fit desired dimensions and angles. Moreover, they exhibit resistance to fire, pests, and moisture, rendering them an ideal selection for framing interior walls and partitions in both commercial and residential structures.

- Q: Are steel angles resistant to UV radiation?

- Steel angles do not naturally possess resistance to UV radiation. However, the degree of resistance can vary based on the type of steel utilized and the application of a protective coating on the surface. When left unprotected, steel angles like hot-rolled or cold-formed steel can undergo deterioration and corrosion when exposed to UV radiation for extended periods. The ultraviolet rays have the ability to induce oxidation in the steel, resulting in the formation of rust and weakening the structure. To counteract the impact of UV radiation, protective finishes such as galvanized zinc, paint, or powder coating can be applied to steel angles. These coatings act as a barrier between the steel and the surroundings, offering protection against UV radiation and preventing oxidation and corrosion. It is important to acknowledge that despite the presence of protective coatings, prolonged exposure to intense UV radiation can still cause some deterioration over time. Therefore, regular inspection and maintenance are crucial in ensuring the durability and structural integrity of steel angles utilized in outdoor or UV-exposed applications.

- Q: How are steel angles welded or joined together?

- Steel angles can be welded or joined together using various techniques such as arc welding, MIG welding, or TIG welding. These methods involve melting and fusing the steel angles together to form a strong and durable joint. Additionally, other joining methods like bolting or riveting can also be used to connect steel angles, depending on the specific application and requirements.

Send your message to us

Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords