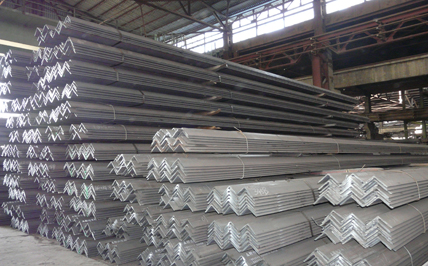

Equal Angle Steel Mild Steel Hot Rolled for Infrastructure Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Working Today, Building Tomorrow!

We do care:

--Good Quality

--On-time Delivery

--Competitive Price

--Efficient After Service

Our products are sold to all over the country and exported to more

than 50 countries such as the EU,theUnitedStates,Australia,Southest,

Asia,the Middle East,etc.

We shall a good -will of credit quality and prompt delivery

and hold the belief of "quality for improvement ,credit for

developments and customer first".So that can offer clients advanced products and satisfied service.

We sincerely would like to set up business relationship with clients

from all over the world in long term business. We view credibility as life.

| Production Standard: | |||||||

| GB/T2101—89;GB9787—88/GB9788—88;JISG3192—94;DIN17100—80;GOCT535—88 | |||||||

| General Specification: | |||||||

| Size (mm) | Weight (kg/m) | Size (mm) | Weight (kg/m) | Size (mm) | Weight (kg/m) | Size (mm) | Weight (kg/m) |

| 25*3 | 1.124 | 70*5 | 5.397 | 100*6 | 9.366 | 70*45*4 | 3.57 |

| 25*4 | 1.459 | 70*6 | 6.406 | 100*8 | 12.276 | 70*45*5 | 4.403 |

| 30*3 | 1.373 | 70*7 | 7.398 | 100*10 | 15.12 | 70*45*6 | 5.218 |

| 30*4 | 1.786 | 70*8 | 8.373 | 100*12 | 17.898 | 100*80*6 | 8.35 |

| 40*3 | 1.852 | 75*5 | 5.818 | 110*8 | 13.532 | 100*80*7 | 9.656 |

| 40*4 | 2.422 | 75*6 | 6.905 | 110*10 | 16.69 | 100*80*8 | 10.946 |

| 40*5 | 2.976 | 75*7 | 7.976 | 110*12 | 19.782 | 110*70*8 | 10.946 |

| 50*4 | 3.059 | 75*8 | 9.03 | 110*14 | 22.809 | 110*70*10 | 13.476 |

| 50*5 | 3.77 | 75*10 | 11.089 | 125*8 | 15.504 | 140*90*8 | 14.16 |

| 50*6 | 4.465 | 80*6 | 7.376 | 125*10 | 19.133 | 140*90*10 | 17.475 |

| 60*5 | 4.57 | 80*8 | 9.658 | 125*12 | 22.696 | 140*90*12 | 20.724 |

| 60*6 | 5.42 | 80*10 | 11.874 | 125*14 | 26.193 | 160*100*12 | 23.592 |

| 63*5 | 4.822 | 90*8 | 10.946 | 140*10 | 21.488 | 160*100*14 | 27.247 |

| 63*6 | 5.721 | 90*10 | 13.476 | 140*12 | 200*125*12 | 29.761 | |

| 63*8 | 7.469 | 90*12 | 15.94 | 200*125*14 | 34.436 | ||

- Q: Can steel angles be galvanized or coated for additional protection?

- Yes, steel angles can indeed be galvanized or coated for additional protection. Galvanizing is a common method used to protect steel from corrosion. It involves coating the steel with a layer of zinc, which acts as a barrier against moisture and other corrosive elements. This process can be done through hot-dip galvanizing, where the steel angle is immersed in a bath of molten zinc, or through electroplating, where a thin layer of zinc is applied to the surface of the steel through an electric current. Coating steel angles with other protective materials is also a viable option. There are various coating options available, such as epoxy, powder coatings, and paint. These coatings create a protective layer on the surface of the steel, shielding it from environmental factors that could lead to corrosion or damage. By galvanizing or coating steel angles, additional protection is provided, extending the lifespan of the material and ensuring its durability in different applications and environments.

- Q: Can steel angles be used in outdoor applications?

- Yes, steel angles can be used in outdoor applications. Steel angles are known for their strength, durability, and resistance to corrosion, making them suitable for various outdoor projects such as construction, infrastructure, and outdoor furniture.

- Q: What are the typical lead times for steel angle orders?

- The typical lead times for steel angle orders can vary depending on the supplier and factors such as quantity, customization, and current demand. However, lead times generally range from a few days to a few weeks. It is recommended to check with the specific supplier for accurate information on lead times.

- Q: How are steel angles tested for quality control?

- To ensure that steel angles meet the required standards and specifications, various testing methods are employed for quality control. Trained inspectors conduct visual inspections to detect surface defects like cracks, dents, or uneven surfaces, which could compromise the angles' structural integrity. Another method used for quality control is dimensional inspection, where measurements of length, width, and thickness are taken to ensure that the angles adhere to specified tolerances. This is crucial as deviations from the required dimensions can affect the angles' performance and fit in different applications. Mechanical testing is also conducted to assess the steel angles' mechanical properties. Tests such as tensile strength, yield strength, and elongation are performed. Tensile strength measures the maximum amount of stress the angles can bear before breaking, while yield strength indicates the stress at which permanent deformation occurs. Elongation determines the angles' ability to stretch without fracturing, providing insights into their ductility. Chemical composition analysis is another critical step in quality control. It verifies that the steel angles contain the correct proportions of alloying elements and impurities. Techniques like spectrometry are utilized to ensure compliance with the required chemical composition standards. Furthermore, non-destructive testing methods are employed to identify internal defects or inconsistencies in the steel angles without causing damage. Techniques such as ultrasonic testing, magnetic particle testing, and radiographic testing are utilized to detect potential flaws like cracks, voids, or inclusions that may not be visible to the naked eye. In summary, a combination of visual inspection, dimensional inspection, mechanical testing, chemical composition analysis, and non-destructive testing is employed to ensure the quality and integrity of steel angles. These rigorous quality control measures guarantee that the angles meet the necessary standards and can perform their intended functions safely and reliably.

- Q: Can steel angles be used in equipment supports?

- Indeed, equipment supports can utilize steel angles. Owing to their robustness and adaptability, steel angles frequently find application in construction and structural contexts. They serve as dependable supports, braces, and reinforcements for diverse equipment and machinery. Given their capacity to withstand substantial loads, steel angles ensure stability and are thus well-suited for industrial equipment support. Moreover, their malleability and capacity for customization make them highly sought-after for equipment support due to their ability to satisfy specific requirements.

- Q: Can steel angles be used as bracing elements?

- Yes, steel angles can be used as bracing elements. Steel angles are often used in construction as bracing elements due to their strength and stability. They can effectively provide support and enhance the structural integrity of a building or structure.

- Q: What are the different types of steel angles used in bridges?

- A variety of steel angles are commonly utilized in bridge construction for different purposes. These include: 1. Equal Leg Angles: These angles possess equal legs and are frequently employed to provide structural support in bridge construction. They contribute stability and strength to the bridge structure. 2. Unequal Leg Angles: These angles have uneven legs and are used when additional strength or specific load-bearing requirements are necessary. They are often combined with equal leg angles to evenly distribute weight and provide support. 3. L-Shaped Angles: L-shaped angles serve various purposes in bridge construction, such as connecting beams and columns or offering additional support at connection points. They are often used in conjunction with other angle types to create a robust and well-supported bridge structure. 4. Tapered Angles: Tapered angles find application in bridges where a change in width or height is required. They are frequently utilized in bridge piers or abutments to ensure a seamless transition between different sections of the bridge. 5. Bent Angles: Bent angles are used in bridges that require a specific angle to accommodate the design or alignment of the bridge. These angles are often custom-made to suit the specific needs of the bridge construction project. 6. Hollow Structural Section (HSS) Angles: HSS angles are hollow steel sections employed in bridge construction to enhance strength and reduce the overall weight of the structure. They are commonly utilized in situations where weight reduction is a priority, such as in long-span bridges or bridges with high load-bearing requirements. Each of these steel angles serves a distinct purpose in bridge construction, and their selection depends on factors such as design requirements, load-bearing capacity, and structural stability necessary for the bridge.

- Q: Can steel angles be used in fencing?

- Yes, steel angles can be used in fencing. Steel angles are commonly used in fencing applications to provide structural support and stability. They can be used as posts or crossbars, depending on the specific fencing design. Steel angles are strong and durable, making them suitable for withstanding the elements and providing security. They can be easily welded or bolted together to create a sturdy fencing structure. Additionally, steel angles can be galvanized or coated to enhance their resistance to rust and corrosion, ensuring a long-lasting and low-maintenance fencing solution.

- Q: What are the design considerations for using steel angles in architectural applications?

- When contemplating the utilization of steel angles in architectural applications, there are several crucial design factors that must be kept in mind. First and foremost, it is of utmost importance to comprehend the structural necessities of the application. Steel angles have the capability to provide exceptional strength and stability. However, their suitability for a specific design hinges upon factors such as the required load-bearing capacity and the necessary structural stability. Consulting a structural engineer is imperative in order to determine the appropriate size, shape, and thickness of the steel angles. This will guarantee that they can securely support the intended loads. Another consideration to take into account is the aesthetic appeal of the steel angles. While they are mainly selected for their structural attributes, they can also contribute to the overall design and visual impact of a building. Architects have the option to choose from a range of finishes, including painted, galvanized, or even stainless steel angles, in order to achieve the desired appearance. The shape and arrangement of the angles can also be utilized creatively to enhance the architectural design and create unique visual effects. Durability is also an essential design factor. Steel angles are renowned for their strength and resistance to corrosion, rendering them suitable for various architectural applications. However, depending on the environmental conditions, additional protective measures may be necessary to prevent rusting or deterioration over time. This can involve applying protective coatings or ensuring proper drainage to prevent water accumulation. Ease of fabrication and installation is also a crucial consideration. Steel angles can be easily fabricated into various shapes and sizes, affording flexibility in design. They can be cut, welded, or bent to meet the specific requirements of the architectural application. Additionally, their standardized sizes and availability make them relatively easy to acquire and install. Finally, cost considerations should not be disregarded. Steel angles generally offer cost-effectiveness compared to other structural materials, such as wood or concrete. However, the overall cost will be contingent upon factors such as the size, finish, and quantity of steel angles required. Striking a balance between the desired design and the available budget is crucial. In conclusion, when contemplating the use of steel angles in architectural applications, it is crucial to thoroughly evaluate the structural requirements, aesthetics, durability, ease of fabrication and installation, and cost considerations. By taking these design factors into careful consideration, architects can make well-informed decisions and ensure the successful integration of steel angles into their designs.

- Q: What is the maximum temperature that steel angles can withstand?

- The maximum temperature that steel angles can withstand depends on the grade of steel used. Generally, low carbon steel angles can withstand temperatures up to 600-700 degrees Celsius (1112-1292 degrees Fahrenheit) before their mechanical properties begin to deteriorate. However, higher carbon steels, stainless steels, or alloy steels can withstand higher temperatures, ranging from 800-1200 degrees Celsius (1472-2192 degrees Fahrenheit) or even higher. It is important to consult the specific material specifications or consult with a materials engineer to determine the maximum temperature a particular steel angle can withstand in a specific application.

Send your message to us

Equal Angle Steel Mild Steel Hot Rolled for Infrastructure Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords