Equal angle steel for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

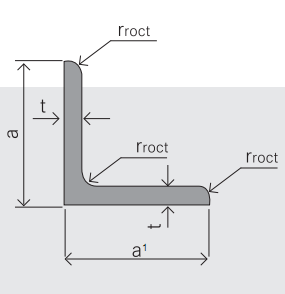

Specifications of Equal Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

.

4.Sizes:

EQUAL ANGLES SIZES | |||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

- Q: Bearing capacity of angle steel and channel steel

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. Also available models that model is the number of centimeters wide, such as angle 3#. The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. Standard Specification for hot-rolled equal angle iron is 2#-20#. The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components. Widely used in a variety of architectural and engineering structures, such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reaction tower, container frame and warehouse.Angle steel performance index: the performance test of angle iron is mainly tensile test and bending test. Indicators include yield point, tensile strength, elongation and bending compliance.

- Q: Can steel angles be galvanized or coated for additional protection?

- Yes, steel angles can indeed be galvanized or coated for additional protection. Galvanizing is a common method used to protect steel from corrosion. It involves coating the steel with a layer of zinc, which acts as a barrier against moisture and other corrosive elements. This process can be done through hot-dip galvanizing, where the steel angle is immersed in a bath of molten zinc, or through electroplating, where a thin layer of zinc is applied to the surface of the steel through an electric current. Coating steel angles with other protective materials is also a viable option. There are various coating options available, such as epoxy, powder coatings, and paint. These coatings create a protective layer on the surface of the steel, shielding it from environmental factors that could lead to corrosion or damage. By galvanizing or coating steel angles, additional protection is provided, extending the lifespan of the material and ensuring its durability in different applications and environments.

- Q: How do steel angles contribute to the overall safety of a building?

- Angle irons, also known as steel angles, play a vital role in improving the overall safety of a building. These structural elements have unique properties and advantages that make them widely used in construction. To begin with, steel angles contribute to the structural support and stability of a building. They are commonly utilized to reinforce and strengthen the framework, particularly at critical load-bearing points. By distributing and transferring weight and forces, steel angles prevent excessive deflection or deformation of the building, ensuring its integrity and stability, even under heavy loads or adverse conditions. This reinforcement is particularly crucial in tall buildings or structures located in earthquake-prone or high-wind regions. Moreover, steel angles enhance the safety of a building by acting as protective barriers or shields against potential hazards. For instance, they can be installed as guards or handrails on staircases, balconies, or elevated platforms. These barriers play a vital role in preventing accidental falls or injuries, creating a secure environment for occupants. Steel angles can also be utilized to create safety barriers around machinery or equipment, preventing unauthorized access or accidental contact. Additionally, steel angles contribute to enhancing fire resistance in buildings. Steel is inherently fire-resistant and does not contribute to the spread of flames. By incorporating steel angles into the structural design of a building, it becomes possible to effectively support fire-rated walls, partitions, or fireproof doors. This facilitates the compartmentalization of the building, slowing down the spread of fire and allowing occupants more time to evacuate safely. Furthermore, steel angles offer longevity and durability, making them an ideal choice for long-term safety. Steel is highly resistant to corrosion, weathering, and other environmental factors, ensuring the structural integrity of the building over time. This durability reduces the risk of sudden structural failures or collapses, thereby enhancing overall safety for occupants and nearby structures. In conclusion, steel angles play a significant role in improving the overall safety of a building. Their ability to provide structural support, act as barriers, enhance fire resistance, and offer durability make them crucial components for ensuring the stability and protection of a structure and its occupants.

- Q: How do steel angles perform in terms of electrical conductivity?

- Steel angles, being made of steel, typically have poor electrical conductivity. Steel is a poor conductor of electricity compared to materials like copper or aluminum. This is due to the high resistance of the steel material, which inhibits the flow of electrons. Therefore, steel angles are not commonly used for electrical applications that require good electrical conductivity. However, steel angles can still be used in certain electrical applications where conductivity is not a critical factor, such as providing structural support in electrical installations.

- Q: Can steel angles be used to create decorative elements in architecture?

- Yes, steel angles can definitely be used to create decorative elements in architecture. These versatile structural components can be bent or shaped into various angles and forms, allowing architects and designers to incorporate them into the overall aesthetic of a building. From ornamental railings and window frames to decorative beams and columns, steel angles offer both strength and design possibilities, making them an ideal choice for decorative elements in architecture.

- Q: How do you calculate the stability factor of a steel angle?

- The stability factor of a steel angle is calculated by dividing the Euler buckling load by the applied compressive load.

- Q: How do steel angles contribute to the overall earthquake resistance of a structure?

- Steel angles contribute to the overall earthquake resistance of a structure in several ways. First and foremost, steel angles are commonly used as reinforcement elements in the construction industry. When properly installed and anchored, they can help increase the overall strength and stability of a structure, making it more resistant to the lateral forces generated during an earthquake. Steel angles are often used to create moment-resisting frames, which are designed to absorb and distribute the seismic energy throughout the structure. These frames, made up of interconnected steel angles, provide a robust system that can effectively resist the horizontal forces exerted by an earthquake. By distributing the seismic load, steel angles help prevent concentrated stress points and potential failure of the structure. Moreover, steel angles can be strategically placed at key locations, such as corners, junctions, and openings, to enhance the overall stiffness and rigidity of the structure. This increased stiffness helps reduce the building's response to seismic vibrations and prevents excessive deformation, which could lead to structural damage. Additionally, steel angles can be used to create diagonal bracing systems, which are essential for mitigating the effects of seismic forces. These systems consist of interconnected steel angles diagonally placed within the structure, forming a network that improves the building's ability to withstand lateral loads. Diagonal bracing effectively dissipates earthquake energy and redirects it away from critical components, thus enhancing the structure's overall earthquake resistance. In summary, steel angles play a crucial role in enhancing the earthquake resistance of a structure. They provide reinforcement, create moment-resisting frames, increase stiffness, and enable the installation of diagonal bracing systems, all of which contribute to the structural integrity and resilience of a building during seismic events.

- Q: Can steel angles support heavy machinery or equipment?

- Yes, steel angles can support heavy machinery or equipment. Steel angles are commonly used in construction and engineering due to their strength and durability. They are typically made from hot-rolled steel and can withstand heavy loads and forces. Steel angles provide structural support and stability, making them suitable for supporting heavy machinery or equipment. They are often used as frames or brackets to hold and secure heavy objects. Additionally, steel angles can be welded or bolted together to create a strong and stable base for heavy machinery. Overall, steel angles are a reliable choice for supporting heavy machinery or equipment due to their high load-bearing capacity and structural integrity.

- Q: What is the process of galvanizing steel angles?

- The process of galvanizing steel angles involves several steps to ensure the steel angles are coated with a layer of zinc for protection against corrosion. Firstly, the steel angles are cleaned to remove any dirt, oil, or rust from the surface. This is typically done through a process called pickling, where the angles are immersed in a solution of acid, usually hydrochloric acid, to remove any impurities. Once the steel angles are cleaned, they are then rinsed to remove any residual acid and dried thoroughly. This is important to ensure proper adhesion of the zinc coating. After the cleaning process, the steel angles are dipped into a bath containing molten zinc. This is done through a process called hot-dip galvanizing, where the angles are fully immersed in the zinc bath. The temperature of the zinc bath is typically around 840°F (449°C). As the steel angles are immersed in the zinc bath, a metallurgical reaction occurs between the steel and the molten zinc. This reaction forms a layer of zinc-iron alloy on the surface of the angles. This layer provides excellent corrosion resistance and acts as a barrier between the steel and the corrosive elements in the environment. After the angles have been fully immersed in the zinc bath, they are then removed and allowed to cool. The cooling process solidifies the zinc coating and ensures its adhesion to the steel angles. Finally, the galvanized steel angles are inspected for quality control. This includes checking the coating thickness, uniformity, and adherence to the angles. Various tests and measurements are performed to ensure that the galvanized coating meets the required standards and specifications. Overall, the process of galvanizing steel angles involves cleaning, immersion in a molten zinc bath, cooling, and inspection. This process provides a durable and long-lasting protective coating on the steel angles, making them resistant to corrosion and extending their lifespan.

- Q: How do you determine the appropriate length of a steel angle for a specific application?

- When determining the appropriate length of a steel angle for a specific application, there are several factors to consider. To begin with, it is necessary to assess the structural requirements of the application. This involves analyzing the loads and forces that the steel angle will experience. It is important to determine the maximum load capacity that the steel angle needs to support and ensure that its length can adequately distribute the load without excessive deflection or failure. Next, the dimensions and layout of the application should be taken into account. The available space should be measured and the fit of the steel angle within the overall structure should be determined. Any constraints, such as adjacent components or obstructions, that may impact the length of the steel angle should also be considered. Furthermore, consulting relevant engineering and construction standards is essential. These codes and guidelines provide recommended design values and specifications for steel angles based on their intended use. They can assist in determining the appropriate length based on the application requirements and the material properties of the steel angle. Additionally, it is important to consider the fabrication and installation process. The manufacturing capabilities and limitations should be evaluated, along with any specific requirements for joining or fastening the steel angle. This will help determine if the desired length is feasible and practical in terms of fabrication and installation methods. Lastly, seeking advice from a structural engineer or a qualified professional in the field is advisable. They can provide expert guidance and calculations based on the specific application, ensuring that the chosen length of the steel angle meets all necessary safety and performance requirements. In conclusion, determining the appropriate length of a steel angle for a specific application involves analyzing the structural requirements, considering the dimensions and layout, referring to relevant standards, evaluating fabrication and installation processes, and seeking professional guidance when required.

Send your message to us

Equal angle steel for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords