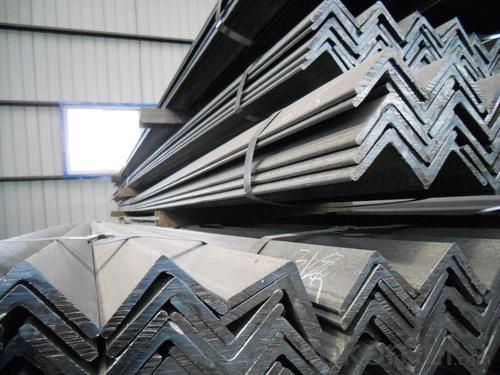

Hot Rolled Equal Angle Steel with High Quality Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Equal Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Equal Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

4.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: How do steel angles perform under seismic loads?

- Steel angles are widely used in construction to provide support and reinforcement for structures. Their inherent properties and design flexibility make them highly effective in seismic conditions. A major advantage of steel angles is their impressive strength-to-weight ratio. This enables them to withstand the intense forces and movements caused by earthquakes without significant deformation or failure. The angle's compact shape also helps distribute the load efficiently, reducing stress concentrations and potential weak points. Furthermore, steel angles can be easily connected to other structural elements, creating a robust and reliable connection system. This is crucial in seismic design, where the ability to transfer forces and accommodate movements is vital. To further enhance their performance under seismic loads, steel angles can be designed with specific features. For example, the addition of stiffeners or bracing elements can increase their resistance to lateral forces, minimizing the risk of buckling or collapse. Using thicker and stronger steel grades can also improve their capacity to absorb and dissipate seismic energy. Various seismic design codes and standards provide guidelines and requirements for the use of steel angles in earthquake-resistant structures. These codes consider factors such as maximum stress levels, connection details, and overall structural behavior during seismic events. In conclusion, steel angles excel in seismic conditions due to their high strength-to-weight ratio, efficient load distribution, and design flexibility. When properly designed and implemented, they effectively withstand the forces and movements generated during earthquakes, ensuring the structural integrity and safety of buildings.

- Q: What are the standard specifications for steel angles?

- Various organizations, such as ASTM and ISO, define the standard specifications for steel angles. These specifications guarantee that steel angles fulfill specific quality and dimensional criteria. ASTM A36 is one of the frequently utilized specifications for steel angles, which encompasses carbon structural steel shapes. According to this specification, steel angles must possess a minimum yield strength of 36,000 psi and a minimum tensile strength ranging from 58,000 to 80,000 psi. The dimensions of the angles are specified in terms of leg length, thickness, and angle size, which can vary from 1/2 inch to 8 inches. Another widely employed specification is ASTM A572, which includes high-strength low-alloy structural steel shapes. Steel angles under this specification need to have a minimum yield strength of 50,000 psi and a minimum tensile strength ranging from 65,000 to 80,000 psi. The dimensions of the angles are similar to those described in ASTM A36. ISO also provides standards for steel angles, such as ISO 657-1 and ISO 657-5. These standards define the dimensions, tolerances, and technical requirements for hot-rolled steel angles. ISO 657-1 pertains to general purpose angles, while ISO 657-5 is concerned with unequal leg angles. Furthermore, steel angles may be subject to specific requirements based on their intended application or industry. For instance, angles used in construction or engineering projects may need to adhere to additional specifications outlined by local building codes or design guidelines. To ensure that steel angles satisfy the necessary requirements for a particular application, it is crucial to consult the relevant standards and specifications. These standards play a vital role in guaranteeing the quality, strength, and dimensional accuracy of the angles.

- Q: Can steel angles be used in residential construction?

- Indeed, residential construction can make use of steel angles. These versatile structural elements find widespread application in various construction projects, including residential buildings. They are commonly employed for framing, reinforcing, and providing structural support in walls, roofs, and floors. In residential construction, steel angles are favored due to their notable strength, durability, and capacity to withstand heavy loads. Their ease of installation, whether by welding, bolting, or screwing, renders them suitable for a wide array of construction endeavors. Furthermore, the corrosion resistance of steel angles can be enhanced through galvanization or coating, assuring their longevity. In essence, steel angles present a dependable and cost-effective option for residential construction.

- Q: What are the common industry standards for steel angles?

- The common industry standards for steel angles are primarily determined by the American Society for Testing and Materials (ASTM). ASTM A36 is a widely recognized standard for structural steel angles and is commonly used in construction and industrial applications. It specifies the chemical composition, mechanical properties, and other relevant characteristics of the steel angles. Another widely used standard is ASTM A572, which is specifically designed for high-strength low-alloy (HSLA) steel angles. It provides guidelines for the chemical composition, mechanical properties, and notch toughness of the angles. Additionally, there are several other ASTM standards such as A529, A588, and A992 that dictate the requirements for specific types of steel angles used in different applications. These standards ensure that steel angles meet the necessary quality and performance criteria, allowing for consistent and reliable use across various industries.

- Q: How are steel angles measured and labeled?

- The dimensions and specifications of steel angles govern their measurement and labeling. When measuring steel angles, two primary parameters are considered: the length of the legs and the thickness of the material. The length of the legs is typically measured in inches or millimeters, indicating the distance from the point where the legs meet to the outer edge of each leg. Similarly, the thickness denotes the cross-sectional measurement of the steel angle and is usually given in inches or millimeters. Steel angles are labeled according to a specific notation system, typically comprising three numbers separated by hyphens or slashes. The initial number represents the length of one leg, the second number represents the length of the other leg, and the third number signifies the thickness of the material. For instance, an angle labeled as "2x2x1/4" implies that both legs have a length of 2 inches and the material thickness is 1/4 inch. Occasionally, steel angles may bear additional information, such as the type of steel employed, the manufacturing standard adhered to, or any distinctive features or characteristics. This supplementary information aids in discerning the specific properties and intended usage of the steel angle. In conclusion, steel angles are measured and labeled based on their dimensions and specifications, employing a standardized notation system that effectively communicates information about their size and thickness.

- Q: How are steel angles made?

- Steel angles are made through a process called hot rolling. It starts with heating a large steel billet in a furnace at very high temperatures until it becomes malleable. The heated billet is then passed through a series of rollers to shape it into the desired angle profile. These rollers have grooves that match the desired angle dimensions, which allow the steel to be gradually formed into the angle shape. As the steel billet is pushed through the rollers, it is compressed and elongated, resulting in a longer and thinner piece of steel with the desired angle shape. This process helps to improve the mechanical properties of the steel, making it stronger and more durable. Once the steel angle is formed, it goes through a cooling process to stabilize its shape and prevent any deformation. It is then cut to the required length and undergoes various finishing processes, including straightening, surface treatment, and inspection, to ensure its quality and dimensional accuracy. Overall, the production of steel angles involves heating, rolling, cooling, cutting, and finishing processes, all designed to create high-quality and precisely shaped steel angles that can be used in various construction and manufacturing applications.

- Q: How does the weight of a steel angle affect its load-bearing capacity?

- The load-bearing capacity of a steel angle is directly impacted by its weight. Generally, a heavier steel angle possesses a greater load-bearing capacity compared to a lighter one. This is due to the weight of the angle contributing to its overall strength and stability. When a load is exerted on a steel angle, it generates both compressive and tensile forces within the material. The weight of the angle aids in evenly distributing these forces, minimizing the likelihood of deformation or failure. Moreover, a heavier steel angle typically signifies a higher density and a larger quantity of material utilized in its construction. Consequently, the angle can endure larger loads without experiencing significant deflection or structural damage. It is crucial to acknowledge that the load-bearing capacity of a steel angle is also influenced by additional factors such as its dimensions, material properties, and the type of connection employed. Nonetheless, the weight of the angle remains a vital consideration in determining its overall strength and ability to support loads.

- Q: Can steel angles be used in electrical or telecommunications applications?

- Yes, steel angles can be used in electrical or telecommunications applications. Steel angles are commonly used as structural supports in various industries, including electrical and telecommunications, due to their strength and durability. They can be used to mount electrical or telecommunications equipment, provide support for cable trays or conduits, and form the framework for equipment racks or cabinets.

- Q: Can steel angles be used as structural supports?

- Yes, steel angles can be used as structural supports. Steel angles are commonly used in construction and engineering projects as they offer excellent strength and stability. They have a unique L-shape design that makes them ideal for providing support and structural integrity to various structures. Steel angles are often used as beams, braces, or supports in buildings, bridges, and other infrastructure projects. They are capable of handling heavy loads and are resistant to bending and compression forces, making them a reliable choice for structural support. Additionally, steel angles can be easily fabricated and installed, making them a cost-effective solution for construction purposes.

Send your message to us

Hot Rolled Equal Angle Steel with High Quality Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords