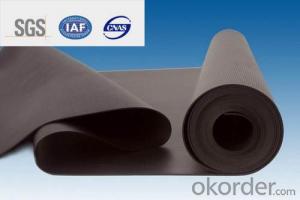

EPDM Waterproofing Roofing Membrane for Roof 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Coil waterproof roofing requirements

- 4, the female wall to leave a waterproof membrane head groove, the height of the project after the completion of the requirements of more than 300 flood height, the general height of 400-500 is appropriate.

- Q: Does a waterproofing membrane require any specific safety precautions during installation?

- Yes, installing a waterproofing membrane does require specific safety precautions. These may include wearing protective clothing, such as gloves and goggles, to prevent contact with chemicals or materials that may be harmful. It is important to ensure proper ventilation in the installation area to minimize exposure to potentially harmful fumes or vapors. Additionally, following manufacturer's instructions, using proper tools and equipment, and working in a well-organized manner can help prevent accidents or injuries during the installation process.

- Q: Can a waterproofing membrane be used for swimming pools and water features?

- Swimming pools and water features can benefit from the utilization of a waterproofing membrane. These specialized membranes serve the purpose of creating a barrier that effectively prevents water from permeating surfaces. They have proven to be highly valuable in a variety of applications, such as swimming pools and water features, where their primary objective is to confine water within the designated area. These membranes are typically crafted from materials that possess water-resistant properties, enabling them to withstand continuous exposure to moisture without incurring damage. Furthermore, their flexibility allows for convenient installation and adaptation to fit pools and water features of varying shapes and sizes. In summary, the implementation of a waterproofing membrane is an efficient and dependable method of guaranteeing the durability and longevity of swimming pools and water features.

- Q: What is the difference between construction non-vulcanized waterproofing membrane and vulcanized waterproofing membrane?

- The advantages of the present invention Is: 1. elongation of permanent deformation is good, after stretching the rebound rate is small, no internal stress, can be fully adapted to the external factors caused by the deformation, there is no accelerated aging after the problem, so the service life can be improved 2-3 Times more than. 2. elongation, up to 1000%. 3. Natural vulcanization of a long time, can reach more than 10 years. 4. Good resistance to low temperature performance. 5. Bonding performance is good. 6. Production costs and operating costs are lower than other existing products.

- Q: Can waterproofing membranes be used on concrete floors?

- Yes, waterproofing membranes can be used on concrete floors. Waterproofing membranes are commonly used in construction to prevent water penetration and protect the underlying structure. When applied to concrete floors, these membranes create a barrier that prevents water from seeping through and causing damage. Waterproofing membranes can be particularly useful in areas such as basements, bathrooms, and outdoor patios where water exposure is common. They help to maintain the integrity of the concrete floor and protect it from moisture-related issues like cracking, spalling, and mold growth.

- Q: Are waterproofing membranes flexible?

- Yes, waterproofing membranes are typically flexible. They are designed to be pliable so that they can conform to the shape and movement of the surfaces they are applied to. This flexibility allows the membranes to effectively seal gaps, cracks, and joints, preventing water from infiltrating into the underlying structure. Furthermore, the flexibility of waterproofing membranes also enables them to withstand the expansion and contraction that occurs due to temperature changes or structural movements. Overall, the flexibility of waterproofing membranes is a crucial characteristic that ensures their durability and effectiveness in protecting structures from water damage.

- Q: Can a waterproofing membrane be used for restaurants or kitchens?

- Yes, a waterproofing membrane can be used for restaurants or kitchens. It provides an effective barrier against water penetration, preventing leaks and water damage. This is particularly important in areas where there is frequent exposure to water, such as kitchens and restaurant facilities. Waterproofing membranes can be applied to various surfaces like floors, walls, and even countertops, ensuring a watertight seal and maintaining a hygienic environment.

- Q: How does a waterproofing membrane perform in areas with heavy foot traffic?

- A protective barrier against moisture and water penetration is the purpose of a waterproofing membrane in various applications. The performance of a waterproofing membrane is crucial in areas with heavy foot traffic. In such areas, the membrane's durability and strength become essential factors. A waterproofing membrane engineered specifically for heavy foot traffic can withstand the constant stress and pressure exerted by people walking, running, or using heavy equipment. Maintaining its integrity and preventing water or moisture from seeping through is one way a waterproofing membrane excels in areas with heavy foot traffic. It acts as a reliable shield, ensuring the underlying structure stays dry and protected. This is particularly important in spaces like balconies, terraces, or concrete walkways where water infiltration can cause structural damage, corrosion, or mold growth. Furthermore, a suitable waterproofing membrane for heavy foot traffic areas should possess excellent abrasion resistance. This means it can endure the friction and wear caused by frequent foot traffic without deteriorating or losing its waterproofing properties. The membrane should resist damage from shoes, heels, or other objects that may come into contact with its surface. Moreover, a waterproofing membrane for heavy foot traffic areas should be slip-resistant to guarantee the safety of individuals walking on it. It should provide sufficient traction and grip, even when wet, to prevent accidents or injuries. This is especially vital in spaces like swimming pool decks or commercial buildings where the risk of slipping is higher. In conclusion, a waterproofing membrane designed for heavy foot traffic areas performs by effectively sealing the surface, preventing water infiltration, and protecting the underlying structure. It should possess durability, strength, abrasion resistance, and slip resistance to ensure optimal performance and safety in areas subjected to heavy foot traffic.

- Q: Can a waterproofing membrane be applied to wood surfaces?

- Yes, a waterproofing membrane can be applied to wood surfaces.

- Q: Can a waterproofing membrane be used for a fountain?

- Yes, a waterproofing membrane can be used for a fountain. Waterproofing membranes are designed to create a protective barrier against water, making them suitable for fountains to prevent leakage and maintain the structural integrity of the fountain.

Send your message to us

EPDM Waterproofing Roofing Membrane for Roof 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords