EPDM Waterproof Membrane Manufacturer with 15-year Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction:

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

2. Product Specification:

There are two installation ways.one is full sticking,the other is hot welding.

Thick | 1.0mm,1.2mm,1.5mm,2.0mm,3.0mm or others |

Width | 1m to 4m |

Length | 20m |

Model | EPDM, EPDM with fabric |

3. Technical Sheet for EPDM Waterproof Membrane:

Number | Item | Unit | Value | |

1 | Size Variation | Thichness | % | ±10 |

Width | % | ±1 | ||

Length | % | Allowed negative | ||

2 | Breaking tensile strength at normal temperature | Mpa | ≥7.5 | |

Breaking tensile strength at 70°C | Mpa | ≥2.3 | ||

3 | Breaking elongation at normal temperature | % | ≥450 | |

Breaking elongation at -20°C | % | ≥200 | ||

4 | Tear strength | KN/m | ≥25 | |

5 | Impermeability(30min) | * | 0.3Mpa no leakage | |

6 | Bending at low tempreture | °C | ≤-40 | |

7 | Stretch tensor at heating | Elongate | mm | ≤2 |

Shrink | mm | ≤4 | ||

8 | Air oven aging(80°C×168h) | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

9 | Anti-alkali | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥80 | ||

10 | Nuture weathing at manual simulation | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

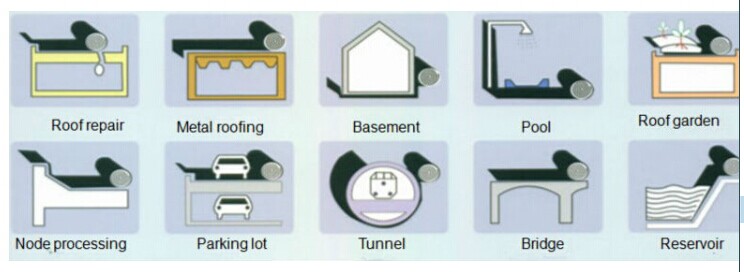

4. Product Application:

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke and subway.

5. Some photos:

- Q: Can a waterproofing membrane be used on EPDM roofs?

- Yes, a waterproofing membrane can be used on EPDM roofs. EPDM roofs are typically made from a rubber material, and a waterproofing membrane can provide an additional layer of protection against water infiltration, extending the lifespan of the roof.

- Q: Can waterproofing membranes be used on expansion joints?

- Yes, waterproofing membranes can be used on expansion joints. These membranes are designed to create a barrier against water penetration and can effectively seal and protect expansion joints from moisture damage.

- Q: What is the purpose of a waterproofing membrane?

- The purpose of a waterproofing membrane is to prevent water and moisture from seeping through surfaces such as roofs, walls, or foundations, thus protecting the underlying structure from water damage and potential leaks.

- Q: Is a waterproofing membrane suitable for use in areas with high groundwater levels?

- Yes, a waterproofing membrane is suitable for use in areas with high groundwater levels. A waterproofing membrane is designed to prevent water penetration and can be effective in creating a barrier against groundwater. These membranes are typically made from materials such as bitumen, PVC, or EPDM, which are highly resistant to water and can withstand high hydrostatic pressure. They are specifically engineered to provide a watertight seal, preventing water from seeping into structures or underground spaces. Therefore, a waterproofing membrane is an ideal solution for areas with high groundwater levels, as it can effectively protect against water intrusion and potential damage to buildings or infrastructure.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels?

- Certainly, it is possible to utilize a waterproofing membrane in regions with elevated groundwater levels. In truth, it is strongly advised to employ a waterproofing membrane in such areas to safeguard the integrity of the edifice from water penetration. The primary purpose of a waterproofing membrane is to construct a barrier that hinders the ingress of water into the building or structure. This becomes particularly crucial in zones with high groundwater levels due to the substantial pressure exerted by the water, which heightens the chances of water damage or flooding. By implementing a waterproofing membrane, you can effectively minimize the risk of water infiltration and ensure the long-lasting resilience of the structure.

- Q: Can a waterproofing membrane prevent mold and mildew growth?

- Yes, a waterproofing membrane can help prevent mold and mildew growth. Mold and mildew thrive in damp and moist environments, and waterproofing membranes create a barrier that prevents water from seeping into the underlying surfaces. By keeping the area dry, the membrane reduces the conditions necessary for mold and mildew to grow. Additionally, some waterproofing membranes are designed with antimicrobial properties, which further inhibit the growth of mold and mildew. However, it is important to note that while a waterproofing membrane can help prevent mold and mildew growth, it is not a foolproof solution. Proper ventilation and maintenance are also crucial in preventing these issues.

- Q: Waterproof membrane in the escape when the full shop, empty shop, shop, shop what is the difference?

- Coil construction process: 1, full of paving the film, the membrane and the base layer with all sticky.

- Q: Can a waterproofing membrane be used for a tunnel?

- Yes, a waterproofing membrane can be used for a tunnel. Waterproofing membranes are commonly used in tunnel construction to prevent water infiltration and protect the tunnel structure from potential damage caused by water. These membranes act as a barrier, preventing the passage of water and ensuring the tunnel remains dry and structurally sound.

- Q: Are there any specific considerations for installing a waterproofing membrane on concrete surfaces?

- Yes, there are several specific considerations for installing a waterproofing membrane on concrete surfaces. Firstly, it is important to ensure that the concrete surface is clean, dry, and free from any loose materials, oil, grease, or other contaminants. Any dirt or debris on the surface can prevent proper adhesion of the waterproofing membrane, compromising its effectiveness. Secondly, it is crucial to inspect the concrete surface for any cracks, spalling, or other damage. These defects should be repaired prior to installing the waterproofing membrane, as they can allow water to penetrate through the membrane and compromise its ability to protect the concrete. Additionally, the type of waterproofing membrane chosen should be suitable for the specific conditions and requirements of the project. There are various types of membranes available, such as sheet membranes, liquid-applied membranes, or cementitious coatings. Each type has different application methods, durability, flexibility, and resistance to various substances, so it is important to select the appropriate membrane for the specific concrete surface and its intended use. Furthermore, the installation of the waterproofing membrane should be carried out in accordance with the manufacturer's instructions. This includes applying the membrane at the recommended thickness, ensuring proper overlap and adhesion of the membrane seams, and using any recommended primers or adhesives. Lastly, it is important to consider the long-term maintenance and durability of the waterproofing membrane. Regular inspections, maintenance, and repairs should be conducted to ensure the membrane remains intact and effective in preventing water penetration.

- Q: Can a waterproofing membrane be certified or approved by industry organizations?

- Yes, a waterproofing membrane can be certified or approved by industry organizations. These organizations typically have stringent standards and testing procedures in place to ensure that the membrane meets certain performance criteria for waterproofing applications. Certification or approval from such organizations provides assurance of the quality and reliability of the product, giving confidence to consumers and industry professionals.

Send your message to us

EPDM Waterproof Membrane Manufacturer with 15-year Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords