EPDM Waterproof Membrane Foundation Elastomeric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

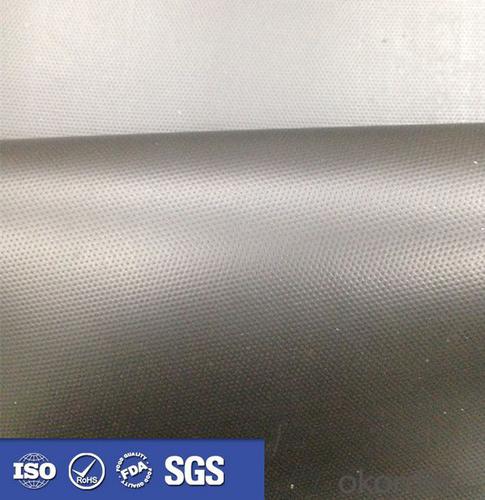

Description Of EPDM Waterproof Membrane Foundation Elastomeric:

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of EPDM Waterproof Membrane Foundation Elastomeric:

1) High tear

2) High puncturing strength

3) Great temperature resistance.

4) High dimensional stability

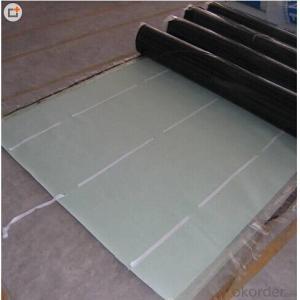

Specifications of EPDM Waterproof Membrane Foundation Elastomeric:

Material | EPDM Waterproof Membrane Foundation Elastomeric |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Waterproof Membrane Foundation Elastomeric:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in government or municipal projects?

- Absolutely, government or municipal projects can most certainly utilize a waterproofing membrane. It is, in fact, a vital element frequently employed in the construction or refurbishment of diverse infrastructure projects like roads, bridges, tunnels, and buildings. The purpose of waterproofing membranes is to thwart water infiltration, which may inflict harm upon the structure and undermine its stability. By incorporating a waterproofing membrane, government and municipal projects can guarantee the endurance and robustness of their infrastructure, thereby diminishing the necessity for costly repairs or replacements in the future. Furthermore, these membranes also contribute to energy efficiency by preventing moisture intrusion, thereby reducing the potential for mold growth and enhancing insulation properties. All in all, it is highly recommended to integrate a waterproofing membrane in government or municipal projects to elevate the lifespan and functionality of the infrastructure.

- Q: Are waterproofing membranes resistant to earthquake-induced water pressure?

- Waterproofing membranes may offer some level of resistance against water pressure caused by earthquakes; however, their effectiveness may vary depending on the specific membrane and the magnitude of the earthquake. The primary purpose of waterproofing membranes is to create a barrier that prevents water infiltration and protects the structure from water damage. However, they are not explicitly engineered to withstand the pressure exerted during earthquakes. During seismic activity, the ground undergoes significant shaking and movement, resulting in increased water pressure in the surrounding soil and groundwater. This heightened pressure can potentially breach the waterproofing membrane, compromising its efficacy. To enhance the resistance of waterproofing membranes to earthquake-induced water pressure, additional measures may be necessary. These measures can involve reinforcing the membrane with shock-absorbing materials, installing drainage systems to alleviate excessive water pressure, and ensuring proper installation and maintenance of the membrane. It is crucial to consult a professional waterproofing expert or structural engineer when selecting a suitable waterproofing system for earthquake-prone areas. These experts can provide guidance on choosing membranes explicitly designed to withstand higher water pressure and offer better protection against earthquakes.

- Q: How does a waterproofing membrane withstand freeze-thaw cycles?

- A waterproofing membrane withstands freeze-thaw cycles by being designed with materials that can expand and contract without losing their integrity. These membranes are typically made of rubber or synthetic polymers that are flexible enough to accommodate the expansion and contraction caused by freezing and thawing temperatures. Additionally, they are formulated to resist water penetration even when subjected to these cyclical temperature changes, ensuring their effectiveness in preventing water damage.

- Q: Can a waterproofing membrane be covered or concealed by other finishes or materials?

- Yes, a waterproofing membrane can be covered or concealed by other finishes or materials. This is commonly done in construction projects to create a visually appealing and functional surface while still ensuring the waterproofing integrity of the structure.

- Q: Can a waterproofing membrane be used for a school building foundation?

- A school building foundation can indeed utilize a waterproofing membrane. These membranes are specifically created to safeguard structures by preventing water from infiltrating. They are commonly employed in various construction scenarios, including building foundations. By applying a waterproofing membrane to the foundation walls, it can effectively shield the building from water-related harm and prevent issues caused by moisture, such as mold, decay, and structural damage. This is especially crucial for school buildings due to their extensive foundations and the possibility of heavy usage and water exposure. Thus, the use of a waterproofing membrane is a viable solution to ensure the durability and structural soundness of the school building foundation.

- Q: Can a waterproofing membrane be used on vinyl surfaces?

- Indeed, one can employ a waterproofing membrane on vinyl surfaces. Vinyl surfaces, including vinyl flooring or vinyl siding, are frequently encountered in both residential and commercial structures. Waterproofing membranes are specifically crafted to establish a barrier against water and moisture, effectively hindering their infiltration into the underlying materials. By applying such membranes onto vinyl surfaces, an extra layer of safeguarding is provided, thereby guaranteeing that the vinyl remains unharmed by water-related issues or decay. Selecting a waterproofing membrane that is compatible with vinyl surfaces is crucial, as is adhering to the manufacturer's instructions for correct application.

- Q: Are waterproofing membranes resistant to acid rain?

- Yes, waterproofing membranes are generally resistant to acid rain due to their ability to protect against water penetration and chemical exposure.

- Q: Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They can effectively prevent water intrusion and protect homes from moisture damage, making them an ideal solution for basements, foundations, roofs, and other areas prone to water leakage.

- Q: Can a waterproofing membrane be used for museums or art galleries?

- Yes, a waterproofing membrane can be used for museums or art galleries. It plays a crucial role in protecting valuable artwork and artifacts from moisture damage, mold, and other environmental factors. By creating a barrier against water penetration, a waterproofing membrane helps to maintain the integrity and longevity of the exhibits, ensuring their preservation and preventing any potential harm caused by moisture.

- Q: Can a waterproofing membrane be used in areas with chemical exposure?

- Yes, a waterproofing membrane can be used in areas with chemical exposure. However, it is essential to choose a membrane specifically designed to withstand the chemicals present in the environment. The membrane should have chemical resistance properties and be compatible with the specific chemicals it will be exposed to in order to provide effective protection against water damage and chemical degradation.

Send your message to us

EPDM Waterproof Membrane Foundation Elastomeric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords