EPDM waterproof membrane for roof basement and pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Rubber Waterproof Membrane for Ponds

Descriptions for EPDM:

GeoGard EPDM offers dependable performance for irrigation reservoirs, canals, aquaculture, dung pits, landfill covers,

waste water reservoirs, constructed wetlands, artificial snow reservoirs, storm water reservoirs, fire reservoirs and

large decorative ponds.

Main Features of EPDM Rubber Waterproof Membrane:

Superior durability

Seamless sheets in 1 piece

Very low life-cycle cost

Flame-free and easy installation

High flexibility and elongation

Environmentally friendly

Recovery of rainwater

Fire resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

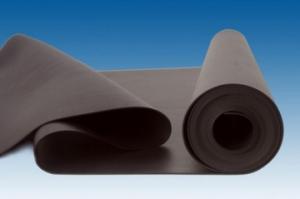

Photo for EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Yes, a waterproofing membrane does require special considerations for installation in seismic zones. Seismic zones are prone to earthquakes and ground movements, which can cause significant stress and strain on the building structure. When installing a waterproofing membrane in such areas, it is crucial to ensure that it can withstand the potential movements and vibrations caused by seismic activities. Some of the special considerations for installing a waterproofing membrane in seismic zones include: 1. Flexibility: The membrane should have sufficient flexibility to accommodate the movement of the building structure during an earthquake. It should be able to stretch, contract, and withstand dynamic forces without tearing or losing its waterproofing properties. 2. Compatibility: The waterproofing membrane should be compatible with the building materials and systems used in seismic zones. It is important to select a membrane that can bond well with the substrate and other construction components to create a seamless and robust waterproofing system. 3. Reinforcement: In high seismic areas, it is recommended to reinforce the waterproofing membrane with additional layers or reinforcements. This can be done by adding a fabric or mesh layer to enhance the membrane's tensile strength and resistance to tearing caused by seismic movements. 4. Proper installation techniques: The installation of the waterproofing membrane in seismic zones should follow specific guidelines and techniques to ensure its effectiveness. It may involve using specific adhesives, primers, or mechanical fastening systems to secure the membrane properly. 5. Quality control: Regular inspections and quality control measures should be implemented during and after the installation process. This helps to identify any potential issues or deficiencies in the waterproofing system, allowing for prompt repairs or adjustments to be made. By addressing these special considerations, the installation of a waterproofing membrane in seismic zones can help protect the building structure from water intrusion and potential damage caused by earthquakes. Consulting with experienced professionals and following industry standards and guidelines is crucial to ensure a successful installation in these challenging environments.

- Q: How does a waterproofing membrane handle cracks in the substrate?

- The purpose of a waterproofing membrane is to prevent water from entering through cracks in the substrate. This is achieved by creating a barrier that stops water from penetrating through the cracks. Typically, the membrane is made from a flexible material like rubber or synthetic polymers, allowing it to stretch and move with the substrate without tearing or breaking. When cracks appear in the substrate, the membrane can bridge over them, maintaining its integrity and preventing water from seeping through. Some membranes even have the ability to self-heal, sealing minor cracks on their own and ensuring continuous protection against water ingress. To improve its ability to bridge cracks, the waterproofing membrane can be reinforced with fibers or fabric layers. These reinforcements enhance the tensile strength and flexibility of the membrane, enabling it to effectively span larger cracks or accommodate movement in the substrate without compromising its waterproofing performance. It is important to consider that the waterproofing membrane's ability to handle cracks in the substrate depends on various factors. These include the type and size of the cracks, the movement of the substrate, and the quality of the membrane installation. To maximize the membrane's ability to handle cracks and provide long-lasting waterproofing protection, it is crucial to follow the manufacturer's guidelines and ensure proper surface preparation and installation techniques.

- Q: Can a waterproofing membrane be used for a school?

- Yes, a waterproofing membrane can be used for a school. Waterproofing membranes are commonly used in construction to prevent water penetration and protect buildings from moisture damage. Installing a waterproofing membrane in areas such as basements, roofs, or exterior walls can help keep the school building dry and safeguard against potential water-related issues.

- Q: Are waterproofing membranes suitable for balconies and terraces?

- Yes, waterproofing membranes are suitable for balconies and terraces as they provide an effective barrier against water infiltration, protecting the underlying structure from potential damage caused by moisture.

- Q: Are waterproofing membranes resistant to acid exposure?

- Yes, waterproofing membranes are generally resistant to acid exposure. They are designed to provide a barrier against water and other corrosive substances, including acids. However, the level of resistance may vary depending on the specific type and quality of the membrane used.

- Q: Can a waterproofing membrane be used for a plaza deck?

- Yes, a waterproofing membrane can be used for a plaza deck. A plaza deck is a flat surface that is usually elevated and exposed to various weather conditions, such as rain, snow, and sunlight. Waterproofing membranes are designed to provide a barrier against water penetration and protect the underlying structure from moisture damage. They are commonly used in outdoor applications, including plaza decks, to prevent water infiltration into the building or structure below. By installing a waterproofing membrane on a plaza deck, it helps to ensure the longevity and durability of the deck, while also providing a safe and dry environment for pedestrians.

- Q: Can a waterproofing membrane be used on precast brick surfaces?

- Yes, a waterproofing membrane can be used on precast brick surfaces. The membrane acts as a barrier to prevent water penetration and protect the underlying structure from moisture damage.

- Q: Can waterproofing membranes be used on elevator pits?

- Yes, waterproofing membranes can be used on elevator pits. Elevator pits are prone to water infiltration due to their location below ground level, making them susceptible to water damage and leaks. Waterproofing membranes provide an effective solution to prevent water penetration and protect elevator pits from moisture-related issues. These membranes are designed to create a watertight barrier, usually made of materials such as rubber, polyurethane, or bitumen. They are applied to the walls and floor of the elevator pit, forming a seamless and durable protective layer. This membrane system helps to keep the pit dry, preventing water damage to the elevator components and ensuring the safe and reliable operation of the elevator.

- Q: Does a waterproofing membrane require any specific cleaning methods?

- Specific cleaning methods are required for a waterproofing membrane. To maintain its effectiveness and longevity, regular cleaning is important. The type of membrane being used will determine the specific cleaning methods, as different materials may have different requirements. It is generally advised to use gentle cleaning solutions and tools, such as a soft brush and mild detergent, to clean the membrane. Avoiding harsh chemicals or abrasive materials that could cause damage is crucial. Furthermore, regularly inspecting the membrane for signs of damage or debris buildup is essential. Addressing these issues promptly can prevent further damage and ensure continued effective waterproofing. It is highly recommended to consult the manufacturer's guidelines and recommendations for proper care and maintenance of the waterproofing membrane.

- Q: Are waterproofing membranes resistant to hydrocarbons?

- Waterproofing membranes are generally resistant to hydrocarbons, meaning they can withstand exposure to substances like oil, gasoline, and diesel. These membranes are designed to block water penetration and are typically made from materials such as bitumen, PVC, TPO, or EPDM. These materials have a natural resistance to hydrocarbons, allowing the membrane to remain effective even when exposed to such substances. However, it's important to consider that the level of resistance may vary depending on the material and its quality. Thus, it is advisable to refer to the manufacturer's specifications and guidelines to ensure the appropriate selection and installation of a hydrocarbon-resistant waterproofing membrane.

Send your message to us

EPDM waterproof membrane for roof basement and pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords