EPDM Waterproof and Breathable Roofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

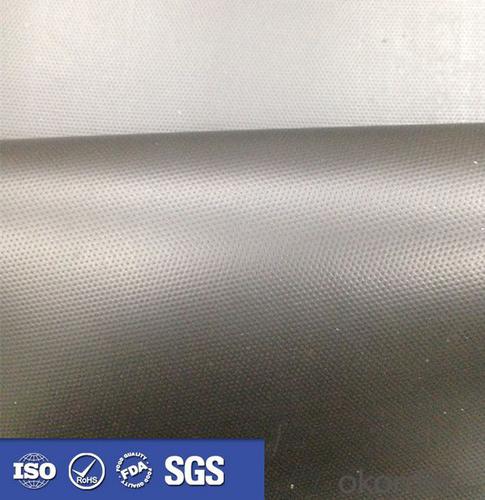

Description Of EPDM Waterproof and Breathable Roofing Membrane:

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of EPDM Waterproof and Breathable Roofing Membrane:

1) High tear

2) High puncturing strength

3) Great temperature resistance.

4) High dimensional stability

Specifications of EPDM Waterproof and Breathable Roofing Membrane:

Material | EPDM Self-adhesive Waterproof Membrane |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Waterproof and Breathable Roofing Membrane:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are waterproofing membranes resistant to sulfuric acid exposure?

- Waterproofing membranes are generally not resistant to sulfuric acid exposure. Sulfuric acid is a highly corrosive substance that can cause severe damage to many materials, including waterproofing membranes. Due to the strong acidic nature of sulfuric acid, it can react with and degrade the membrane, leading to its failure. Therefore, if there is a possibility of sulfuric acid exposure, it is important to use acid-resistant materials specifically designed to withstand such corrosive substances.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Yes, a waterproofing membrane can be used for theaters or concert halls. Waterproofing membranes are commonly used in construction to protect buildings from water damage. The membrane can be applied to various surfaces, including walls, floors, and roofs, helping to prevent water penetration and moisture-related issues. In theaters or concert halls, where there may be a significant risk of water damage due to heavy rain, leaks, or potential spills, using a waterproofing membrane can provide an extra layer of protection and help preserve the structural integrity of the building.

- Q: Can a waterproofing membrane be used in conjunction with fire protection systems?

- Indeed, the utilization of a waterproofing membrane in tandem with fire protection systems is possible. Although the primary function of a waterproofing membrane is to prevent water infiltration, it can also serve as an additional safeguard against fire hazards. Numerous waterproofing membranes are engineered to possess fire-resistant qualities or exhibit fire-retardant characteristics. Consequently, they aid in impeding the spread of fire and minimizing its impact on the edifice. Furthermore, certain waterproofing membranes are specifically tailored for integration into fire protection systems, such as fire-rated roof membranes or fire-resistant sealants. These specialized membranes effectively seal off potential avenues for fire and establish a barrier to safeguard the underlying structure. In summary, the incorporation of a waterproofing membrane alongside fire protection systems contributes to the overall enhancement of a building's safety and security.

- Q: Can a waterproofing membrane be used on tunnels with railway systems?

- Yes, a waterproofing membrane can be used on tunnels with railway systems. The membrane helps to prevent water ingress and moisture damage to the tunnel structure, ensuring the safety and longevity of the railway system.

- Q: Can a waterproofing membrane be used for a crawl space?

- Indeed, a crawl space can benefit from the application of a waterproofing membrane. Given their vulnerability to moisture and water infiltration, crawl spaces can experience a range of problems including the growth of mold, structural deterioration, and unpleasant odors. By employing a waterproofing membrane, the infiltration of water and moisture into the crawl space can be effectively impeded. Typically, this membrane is affixed to the walls and floors of the crawl space, forming a secure seal that prevents any water from seeping through. Consequently, this membrane serves as an exceptional remedy for the waterproofing of crawl spaces. Furthermore, certain waterproofing membranes possess antimicrobial properties, thereby further diminishing the likelihood of mold and mildew growth within the crawl space.

- Q: Can a waterproofing membrane be used on concrete block walls?

- Yes, a waterproofing membrane can be used on concrete block walls. Concrete block walls are susceptible to water penetration, which can lead to issues such as mold, mildew, and structural damage. A waterproofing membrane is a protective barrier that is applied to the surface of the concrete block walls to prevent water from seeping through. It acts as a barrier against moisture, creating a watertight seal and preventing water from entering the interior of the walls. This helps to maintain the integrity of the walls and protect against water-related damages. However, it is important to ensure that the waterproofing membrane is properly installed and that any existing cracks or gaps in the concrete block walls are adequately sealed before applying the membrane.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Yes, a waterproofing membrane can be used in crawlspaces or basements. In fact, it is highly recommended to use waterproofing membranes in these areas to prevent moisture infiltration and water damage. Crawlspaces and basements are prone to water seepage and high humidity levels, which can lead to mold growth, structural issues, and damage to stored items. A waterproofing membrane acts as a barrier against water intrusion by effectively sealing the foundation walls and floor. It creates a watertight seal that prevents water from seeping into the space, keeping it dry and protected. Additionally, waterproofing membranes also help to control moisture levels by reducing condensation and humidity, thereby creating a healthier and more comfortable environment. Overall, using a waterproofing membrane in crawlspaces or basements is an essential measure to ensure the longevity and integrity of the structure and to safeguard against potential water-related problems.

- Q: Can a waterproofing membrane be applied to curved or irregular surfaces?

- Indeed, it is possible to apply a waterproofing membrane to surfaces that are curved or irregular. In the market, there exist flexible waterproofing membranes that have the ability to adapt to different shapes and contours. These membranes have been designed to be stretchable, allowing for manipulation in order to perfectly fit curved or irregular surfaces while still maintaining their excellent waterproofing properties. It is crucial to select a membrane that is explicitly designed for these types of applications and to adhere to correct installation techniques to guarantee a secure and watertight seal.

- Q: Can a waterproofing membrane be used for bridges and overpasses?

- Yes, a waterproofing membrane can be used for bridges and overpasses. Waterproofing membranes are commonly used in the construction industry to protect structures from water infiltration, including bridges and overpasses. These membranes are designed to create a barrier between the structure and moisture, preventing water from seeping into the concrete or steel components. By installing a waterproofing membrane, the lifespan of a bridge or overpass can be significantly extended, as it helps to prevent corrosion, concrete degradation, and other damages caused by water exposure. Additionally, waterproofing membranes can also provide protection against other environmental factors such as freeze-thaw cycles, chemicals, and UV radiation. Therefore, using a waterproofing membrane for bridges and overpasses is a common practice to enhance their durability and longevity.

- Q: Are there any specific building code requirements for waterproofing membranes?

- Yes, there are specific building code requirements for waterproofing membranes. Building codes vary by jurisdiction, but most codes require that waterproofing membranes meet certain standards and specifications. These requirements are put in place to ensure that buildings are adequately protected from water damage and to maintain the safety and integrity of the structure. Some common building code requirements for waterproofing membranes include: 1. Material standards: The building code may specify the type of materials that can be used for waterproofing membranes. This can include specifications for the type of membrane, such as liquid-applied or sheet membranes, as well as the required thickness and composition. 2. Installation standards: The building code may outline specific installation methods and techniques for waterproofing membranes. This can include requirements for proper surface preparation, application procedures, and detailing around penetrations and transitions. 3. Testing and certification: Building codes may require that waterproofing membranes undergo certain tests and meet specific performance criteria. This can include tests for resistance to water penetration, durability, and compatibility with other building materials. In some cases, the code may require that the waterproofing membrane be certified by a recognized testing laboratory. 4. Code compliance documentation: Building codes often require that waterproofing membranes be installed in accordance with approved plans and specifications. This means that contractors may need to submit documentation to demonstrate compliance with the code, such as product data sheets, manufacturer's installation instructions, and details of the proposed waterproofing system. It is important to consult the local building code or regulatory authority to determine the specific requirements for waterproofing membranes in a particular jurisdiction. Compliance with these requirements is essential to ensure the proper functioning and longevity of the waterproofing system and to avoid potential issues such as water intrusion, mold growth, and structural damage.

Send your message to us

EPDM Waterproof and Breathable Roofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords