EPDM Rubber Waterproof Membrane NO.1 CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

Product Instruction:

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

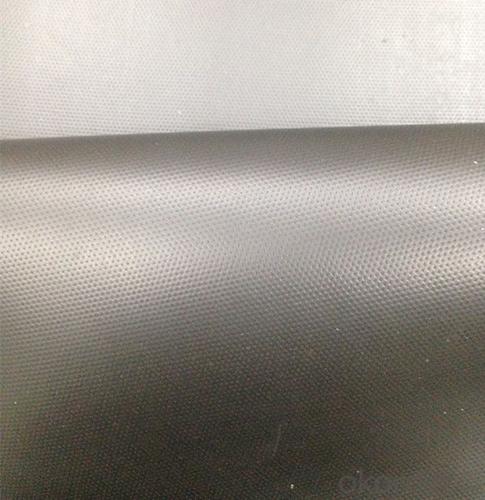

Photos:

- Q: Are waterproofing membranes suitable for tunnels?

- Yes, waterproofing membranes are suitable for tunnels. Tunnels are often subjected to high water pressure from the surrounding soil and groundwater, making them vulnerable to water ingress. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively prevent water from entering the tunnel structure. These membranes are typically made of durable materials such as bitumen, PVC, or EPDM rubber, which are resistant to water penetration. They are applied to the tunnel walls and ceiling to create a continuous, impermeable layer that keeps the tunnel dry. The membranes are also flexible, allowing them to accommodate any movement or settlement of the tunnel without compromising their waterproofing integrity. In addition to preventing water infiltration, waterproofing membranes also offer other benefits for tunnels. They can protect the tunnel structure from corrosion caused by water and chemicals, prolonging its lifespan. They can also help to improve the indoor air quality within the tunnel by preventing the growth of mold and mildew, which thrive in damp environments. Furthermore, waterproofing membranes can be customized to suit different tunnel conditions. For example, in tunnels that are exposed to high levels of hydrostatic pressure, reinforced membranes with higher tensile strength can be used to withstand the added stress. Additionally, membranes with enhanced fire resistance properties can be utilized in tunnels where fire safety is a concern. Overall, waterproofing membranes are a reliable and effective solution for ensuring the durability, safety, and longevity of tunnels by providing a robust barrier against water ingress.

- Q: SBS waterproofing membrane how to sample

- SBS modified asphalt waterproofing membrane, APP modified asphalt waterproofing membrane: the same manufacturers, the specifications are not more than 10000m2 for a number of qualified qualified coil, each batch of random 1

- Q: Does a waterproofing membrane have any impact on the thermal performance of a structure?

- The thermal performance of a structure can be influenced by a waterproofing membrane. Usage of a waterproofing membrane is common in buildings to prevent water infiltration, which can harm the structure over time. By creating a barrier against moisture, the membrane helps maintain the building envelope's integrity and safeguards against potential leaks or water damage. Regarding thermal performance, a waterproofing membrane can enhance insulation by reducing heat transfer through the building envelope. By preventing moisture from entering the structure, the membrane also prevents condensation formation, which can lead to mold growth and further damage to building materials. Moreover, certain waterproofing membranes are designed with additional insulation properties, such as foam or reflective coatings, which further improve a structure's thermal performance. These membranes decrease thermal bridging and enhance energy efficiency by minimizing heat loss or gain through the building envelope. It should be noted that the impact of a waterproofing membrane on a structure's thermal performance can vary depending on the specific type of membrane, its installation, and the overall building design. Consulting a professional architect or engineer is advisable to determine the most suitable waterproofing solution that meets both water resistance and thermal performance requirements for a particular structure.

- Q: Can waterproofing membranes be used on shower walls?

- Yes, waterproofing membranes can indeed be used on shower walls. In fact, they are an essential component of shower construction to prevent water leakage and potential damage to surrounding areas. Waterproofing membranes create a barrier that prevents water from seeping through the walls and into the structural components of the shower. They are typically installed behind the tile or other wall covering materials to provide an extra layer of protection. Waterproofing membranes are designed to be flexible, durable, and resistant to moisture, ensuring that the shower walls remain watertight and free from any potential water damage.

- Q: Can waterproofing membranes be used on expansion joints?

- Yes, waterproofing membranes can be used on expansion joints. These membranes are designed to create a barrier against water penetration and can effectively seal and protect expansion joints from moisture damage.

- Q: Can a waterproofing membrane be installed by a homeowner, or is professional installation necessary?

- While it is technically possible for a homeowner to install a waterproofing membrane, professional installation is highly recommended. Waterproofing membranes require specialized knowledge and expertise to ensure proper installation and effectiveness. Professionals have the necessary skills, tools, and experience to address potential challenges and ensure a long-lasting and reliable waterproofing solution. Additionally, professional installation often comes with warranties and guarantees, providing homeowners with added peace of mind.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Yes, a waterproofing membrane can be used on below-grade walls to prevent water infiltration and moisture damage.

- Q: Does a waterproofing membrane affect the structural integrity of a building?

- No, a waterproofing membrane does not typically affect the structural integrity of a building. In fact, it is designed to protect the structural components of a building by preventing water infiltration and subsequent damage. A waterproofing membrane acts as a barrier against water penetration, ensuring that the building remains dry and free from moisture-related issues such as mold, rot, or deterioration. By keeping the building envelope intact, a waterproofing membrane helps maintain the structural integrity of the building and extends its lifespan. It is important to note that the installation of a waterproofing membrane should be done correctly and in accordance with industry standards to ensure its effectiveness and avoid any potential negative impact on the structure.

- Q: Can a waterproofing membrane be used for parking structures or garages?

- Parking structures or garages can benefit from the use of a waterproofing membrane. Due to their exposure to harsh weather conditions, these structures are susceptible to water damage. To counter this, a waterproofing membrane acts as a protective barrier, preventing water from seeping into the concrete or other materials. By doing so, it effectively prevents issues like corrosion, cracking, and deterioration. Moreover, it also offers protection against elements such as chemicals, oils, and salts commonly found in parking areas. Therefore, it is highly advisable to incorporate a waterproofing membrane to enhance the longevity and durability of parking structures and garages.

- Q: Can a waterproofing membrane be used for a stadium roof structure?

- Yes, a waterproofing membrane can be used for a stadium roof structure. A waterproofing membrane is a protective layer that prevents water from penetrating the roof and causing damage. It is typically made of materials such as rubber or synthetic polymers that are resistant to water. In the case of a stadium roof structure, a waterproofing membrane can be used to ensure that the roof remains watertight and prevents any leaks or water damage. This is particularly important for stadiums that have open-air or retractable roofs, as they are exposed to the elements and are more susceptible to water infiltration. A waterproofing membrane can be applied to various types of stadium roof structures, including metal, concrete, or even fabric roofs. It is typically installed beneath the roofing material, acting as a protective barrier against water. By preventing water from seeping into the roof, the membrane helps to extend the lifespan of the roof and protect the interior of the stadium from water damage. Additionally, a waterproofing membrane can also provide other benefits for a stadium roof structure. It can help to improve energy efficiency by reducing heat loss or gain through the roof. Some membranes also offer UV resistance, which helps to protect the roof from damaging ultraviolet rays. Overall, using a waterproofing membrane for a stadium roof structure is a practical and effective solution to ensure the roof remains watertight, durable, and protected from water damage.

Send your message to us

EPDM Rubber Waterproof Membrane NO.1 CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords