EPDM roof pond waterproof membrane with SGS ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Rubber Waterproof Membrane for Ponds

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

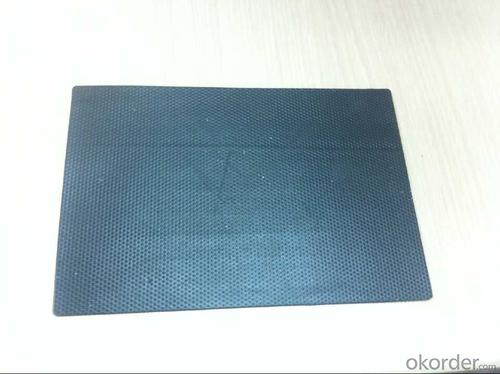

IMages of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are waterproofing membranes resistant to high temperatures?

- The resistance of waterproofing membranes to high temperatures may vary depending on the specific material utilized. Certain waterproofing membranes are specifically engineered to endure high temperatures while retaining their effectiveness and integrity. These membranes often comprise materials like modified bitumen or synthetic rubber, which possess properties that enable them to withstand elevated temperatures. Nevertheless, it should be noted that not all waterproofing membranes possess resistance to high temperatures. Some membranes constructed from PVC or other thermoplastic materials may have limitations when exposed to extreme heat. Therefore, it is imperative to refer to the manufacturer's specifications and guidelines to ensure that the selected waterproofing membrane is appropriate for the intended application and can endure the expected temperature conditions.

- Q: Are there any specific considerations for installing a waterproofing membrane on metal surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on metal surfaces. When installing a waterproofing membrane on metal surfaces, it is important to consider the compatibility of the membrane with the specific type of metal being used. Some waterproofing membranes may not adhere well to certain types of metal surfaces, so it is necessary to choose a membrane that is specifically designed for use on metal. Additionally, it is important to ensure that the metal surface is properly prepared before installing the waterproofing membrane. This may involve cleaning the surface thoroughly to remove any dirt, grease, or other contaminants that could interfere with the adhesion of the membrane. It may also be necessary to prime the metal surface to improve adhesion. Another consideration is the expansion and contraction of the metal surface due to temperature changes. Metal surfaces can expand and contract significantly with temperature variations, and this movement can potentially affect the performance of the waterproofing membrane. Therefore, it is important to choose a membrane that can accommodate the movement of the metal without compromising its waterproofing capabilities. Furthermore, it is essential to consider the type of waterproofing membrane being used. There are different types of membranes available, including liquid-applied membranes, sheet membranes, and peel-and-stick membranes. Each type of membrane has its own installation requirements, so it is crucial to follow the manufacturer's guidelines to ensure proper installation on metal surfaces. Lastly, it is important to consider any additional factors that may affect the performance of the waterproofing membrane on metal surfaces. These factors can include exposure to UV radiation, potential for corrosion, and compatibility with other building materials or systems. Taking these considerations into account will help ensure a successful and long-lasting installation of a waterproofing membrane on metal surfaces.

- Q: Polyethylene polypropylene waterproofing membrane forming. Secondary molding, what does it mean? How to distinguish?

- Polyethylene polypropylene waterproofing membrane from the middle of the "polyethylene" chip, two-sided composite "polypropylene non-woven" made, one method is in the extrusion production of polyethylene film at the same time, when the polyethylene is still in a soft state , In the upper and lower sides of the membrane composite polypropylene non-woven, the temperature can not be too high and polypropylene buried too much, the temperature can not be too low, otherwise the sticky on the sticky.

- Q: Can a waterproofing membrane be used for wastewater treatment plants?

- Yes, a waterproofing membrane can be used for wastewater treatment plants. Waterproofing membranes are commonly used in various construction projects, including wastewater treatment plants, to provide a protective barrier against water infiltration. These membranes are designed to prevent water from seeping into the structure, which is crucial for wastewater treatment plants as they deal with large volumes of water. Wastewater treatment plants are exposed to constant water exposure and high humidity levels, which can lead to moisture damage and structural deterioration. By installing a waterproofing membrane, the facility can effectively prevent water penetration, ensuring the integrity and longevity of the structure. Furthermore, wastewater treatment plants often contain various corrosive chemicals and substances that can cause damage to the structure over time. Waterproofing membranes can act as a protective layer, preventing these chemicals from corroding the building materials and causing structural issues. There are different types of waterproofing membranes available, including sheet membranes, liquid membranes, and cementitious membranes. The choice of membrane depends on the specific requirements, budget, and conditions of the wastewater treatment plant. It is essential to select a membrane that is compatible with the chemicals present in the wastewater and can withstand the harsh conditions of the facility. In conclusion, a waterproofing membrane is a suitable solution for wastewater treatment plants as it effectively protects the structure from water infiltration and chemical damage. By implementing a proper waterproofing system, the facility can ensure the long-term durability and functionality of the plant.

- Q: Does a waterproofing membrane prevent water vapor transmission?

- Yes, a waterproofing membrane is designed to prevent both liquid water and water vapor from penetrating through a surface. It acts as a barrier that blocks the movement of moisture, including water vapor, thus preventing water intrusion and potential damage to the underlying structure. Waterproofing membranes are commonly used in various applications such as roofs, basements, and bathrooms to ensure the integrity and durability of the building envelope.

- Q: Can a waterproofing membrane be used for bridge decks and roadways?

- Yes, a waterproofing membrane can be used for bridge decks and roadways. Waterproofing membranes are designed to provide a protective layer that prevents water infiltration, which is essential for the long-term durability and performance of bridge decks and roadways. These membranes help to prevent water damage, such as corrosion and cracking, and also protect the underlying structure from moisture-related issues.

- Q: What is the difference between polymer waterproofing membrane and cross film waterproofing membrane?

- he strong cross-over film of the product is a high-strength HDPE film formed by the cross-laminating process. The film and the like have the same vertical and transverse elongation ratio. The coil does not send deformation, more beautiful and waterproof reliable.

- Q: Can a waterproofing membrane be used for a school building foundation?

- A school building foundation can indeed utilize a waterproofing membrane. These membranes are specifically created to safeguard structures by preventing water from infiltrating. They are commonly employed in various construction scenarios, including building foundations. By applying a waterproofing membrane to the foundation walls, it can effectively shield the building from water-related harm and prevent issues caused by moisture, such as mold, decay, and structural damage. This is especially crucial for school buildings due to their extensive foundations and the possibility of heavy usage and water exposure. Thus, the use of a waterproofing membrane is a viable solution to ensure the durability and structural soundness of the school building foundation.

- Q: Can a waterproofing membrane be installed in areas with high humidity?

- Yes, a waterproofing membrane can be installed in areas with high humidity. In fact, high humidity can be a contributing factor to the need for waterproofing as it can lead to moisture buildup and potential water damage. Waterproofing membranes are designed to create a barrier against water penetration, regardless of the humidity levels in the area. However, it is important to ensure that the membrane is properly installed and sealed to prevent any moisture from seeping through. Additionally, it may be necessary to take extra precautions in areas with high humidity, such as using a moisture barrier or dehumidifiers, to further protect against potential water damage.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Certainly! Waterproofing membranes can be applied to tunnels that have emergency exits. It is strongly advised to utilize a waterproofing membrane in these tunnels to prevent water infiltration and safeguard the integrity of the exits. These membranes are specifically designed to establish a barrier against water and moisture, guaranteeing that the tunnels stay dry and unharmed by water. This is particularly crucial for emergency exits, as they must remain accessible and operational under all circumstances. By installing a waterproofing membrane, the tunnels can be adequately shielded from potential water ingress, thus ensuring the safety and functionality of the emergency exits.

Send your message to us

EPDM roof pond waterproof membrane with SGS ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords