EPDM Pond Liner Manufacturer In China for 10 Years Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

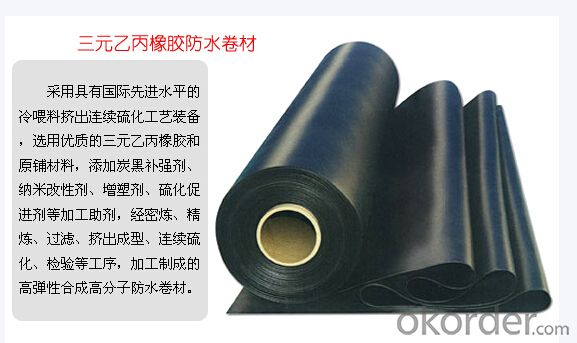

1. Introduction of EPDM Waterproofing Membrane:

EPDM pond liners adopt the international advanced level cold feed extrusion continuous vulcanization process for the integration of production equipment and technology so that the system density of products is better and the products have no bubble sooth surface, no performance difference between vertical and horizontal.

2. Specification of EPDM Waterproofing Membrane:

Type | EPDM |

Material | EPDM Rubber |

Thickness | 1.2mm,1.5mm,2.0mm |

Length | 20m/roll |

Width | 1.2m |

Usage | roof/walls/bathroom/tunnel/basement/bridge/road/underground, |

Application method | Hot melt |

Length | 20m |

Surface | Smooth surface,fleece surface |

3. Application of EPDM Waterproofing Membrane:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building

waterproofing, reservoir, bridge, underground, tunnel and dam waterproofing ,especially to the keystone

waterproofing projects which is durability, high corrosion resistance and easy deformation

4. Some photos:

- Q: Can a waterproofing membrane be used for a planter box?

- Yes, a waterproofing membrane can be used for a planter box. A waterproofing membrane is designed to prevent water from penetrating the surface it is applied to, making it an ideal choice for protecting the planter box from moisture damage. By applying a waterproofing membrane to the interior of the planter box, it helps to create a barrier that prevents water from seeping through and potentially causing damage to the wood or material of the planter box. This can be particularly useful in situations where the planter box is constantly exposed to water, such as when used outdoors or for hydroponic gardening. Overall, using a waterproofing membrane for a planter box can help to extend its lifespan and ensure that it remains in good condition for a longer period of time.

- Q: What is the meaning of the node and the additional layer in the construction of the membrane waterproofing layer?

- In general, these places are also the most vulnerable areas, need to focus on processing.

- Q: Can a waterproofing membrane be used in temporary or temporary structures?

- Indeed, temporary or transient structures can benefit from the utilization of a waterproofing membrane. These specialized membranes are crafted to establish a safeguard against the infiltration of water, a critical measure in thwarting any potential moisture-related harm in various architectural formations. Be it a fixed or impermanent construction, such as a provisional refuge, tent, or temporary worksite, the application of a waterproofing membrane guarantees the attainment of water resistance and protection. Consequently, it becomes imperative to meticulously select a waterproofing membrane that aligns with the distinct requisites of the temporary structure, while adhering to the appropriate installation protocols to ensure its utmost efficacy.

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Special considerations must be taken into account when installing a waterproofing membrane in seismic zones due to the risk of earthquakes and ground movements. To withstand the potential movements and vibrations caused by seismic activities, it is crucial to ensure that the membrane is capable of withstanding stress and strain. When installing a waterproofing membrane in seismic zones, several factors should be considered: 1. Flexibility: The membrane should possess sufficient flexibility to accommodate the movement of the building structure during an earthquake. It should be able to stretch, contract, and withstand dynamic forces without tearing or compromising its waterproofing properties. 2. Compatibility: It is important to select a waterproofing membrane that is compatible with the building materials and systems used in seismic zones. This ensures that the membrane bonds well with the substrate and other construction components, creating a seamless and robust waterproofing system. 3. Reinforcement: In areas with high seismic activity, it is recommended to reinforce the waterproofing membrane with additional layers or reinforcements. This can be achieved by incorporating a fabric or mesh layer to enhance the membrane's tensile strength and resistance to tearing caused by seismic movements. 4. Proper installation techniques: The installation of the waterproofing membrane in seismic zones should adhere to specific guidelines and techniques to ensure its effectiveness. This may involve using specific adhesives, primers, or mechanical fastening systems to securely install the membrane. 5. Quality control: Regular inspections and quality control measures should be implemented during and after the installation process. This allows for the identification of any potential issues or deficiencies in the waterproofing system, enabling prompt repairs or adjustments to be made. By addressing these special considerations, the installation of a waterproofing membrane in seismic zones can effectively safeguard the building structure against water intrusion and potential damage caused by earthquakes. Consultation with experienced professionals and adherence to industry standards and guidelines are imperative for a successful installation in these challenging environments.

- Q: Can a waterproofing membrane be used on tunnels with subway systems?

- Yes, a waterproofing membrane can be used on tunnels with subway systems. Waterproofing membranes are commonly used in underground construction projects, including tunnels and subway systems, to prevent water infiltration. These membranes act as a protective barrier, preventing water from entering the tunnel and causing damage to the infrastructure. By using a waterproofing membrane, the tunnel structure can be effectively protected and the subway system can operate safely and efficiently.

- Q: Can a waterproofing membrane be used on PVC roofs?

- Yes, a waterproofing membrane can be used on PVC roofs. PVC roofs are commonly used in commercial and residential buildings, and applying a waterproofing membrane can provide an additional layer of protection against water damage and leaks. The membrane is typically made of materials such as synthetic rubber or thermoplastic that are specifically designed to prevent water penetration. By installing a waterproofing membrane on a PVC roof, it can enhance its durability and extend its lifespan.

- Q: Can a waterproofing membrane be used in areas with chemical exposure, such as industrial settings?

- Yes, a waterproofing membrane can be used in areas with chemical exposure, such as industrial settings. Waterproofing membranes are designed to provide protection against water penetration and can also offer resistance to certain chemicals. However, the specific type of waterproofing membrane and its chemical resistance properties should be carefully selected to ensure compatibility with the specific chemicals present in the industrial setting. Consulting with a professional or manufacturer is advised to ensure proper selection and installation of a waterproofing membrane in such environments.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Yes, a waterproofing membrane can definitely be used in conjunction with green building practices. In fact, incorporating a waterproofing membrane into the construction of a green building can help enhance its overall sustainability and efficiency. One of the key principles of green building practices is to maximize energy efficiency and reduce the environmental impact of a building. By installing a waterproofing membrane, the building's envelope can be protected from moisture intrusion, preventing water damage and potential mold growth. This, in turn, helps maintain the structural integrity of the building, reducing the need for repairs and replacements, which can be resource-intensive and generate waste. Additionally, a waterproofing membrane can contribute to better indoor air quality. By preventing water infiltration, it helps create a dry and healthy living or working environment, minimizing the risk of respiratory issues and other health problems associated with dampness. Furthermore, a waterproofing membrane can improve the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it reduces the potential for heat loss through moisture evaporation, thus reducing the energy needed for heating and cooling. This can lead to reduced energy consumption and lower carbon emissions, aligning with the goals of green building practices. It is important, however, to choose a waterproofing membrane that is environmentally friendly and meets green building standards. Look for membranes that are made from recycled or sustainable materials and have low VOC (volatile organic compound) content. Additionally, consider selecting a membrane that is designed for durability and longevity, as this can further reduce the environmental impact by minimizing the need for replacement over time. In conclusion, a waterproofing membrane can be a valuable addition to any green building project. It helps protect the building envelope, improves indoor air quality, and enhances energy efficiency. By selecting an environmentally friendly membrane, the overall sustainability of the building can be further improved.

- Q: Can a waterproofing membrane be used in foundations?

- Foundations can benefit from the use of a waterproofing membrane. Installing such a membrane is often recommended to prevent water infiltration and protect the structure from potential damage. This barrier is typically applied to the exterior walls of the foundation, effectively blocking water penetration. By keeping the foundation dry, it safeguards against cracks and leaks caused by hydrostatic pressure. Moreover, a waterproofing membrane helps prevent moisture buildup, mold growth, and other water damage-related issues. Overall, incorporating a waterproofing membrane in foundations is a dependable and effective approach to ensure the long-lasting stability and durability of a building.

- Q: How long do waterproofing membranes typically last?

- The typical lifespan of waterproofing membranes ranges from 20 to 30 years, with various factors influencing their durability. These factors include the membrane's quality, installation method, and maintenance practices. Membranes of higher quality and those installed and maintained properly can last closer to 30 years. Conversely, lower-quality membranes or those exposed to harsh conditions may have a shorter lifespan. Regular inspections and prompt repairs can also contribute to extending the longevity of waterproofing membranes. It is crucial to recognize that these estimates are general and the actual lifespan may differ based on specific circumstances and conditions of membrane usage.

Send your message to us

EPDM Pond Liner Manufacturer In China for 10 Years Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords