Membrane EPDM Vulcanization 1.5mm for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

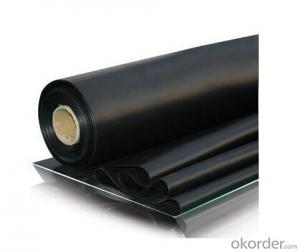

EPDM Membrane Vulcanization for Waterproof System

Description Of EPDM Membrane Vulcanization1.5mm:

1. EPDM membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

Main Features of EPDM Vulcanization1.5mm:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

Specifications of EPDM Vulcanization1.5mm:

Material | Ternary Ethylene-Propylene rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Type | Vulcanized |

Applications of EPDM Rubber Vulcanization1.5mm:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

IMages of EPDM Vulcanization1.5mm:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane,Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can waterproofing membranes be applied in cold weather?

- Yes, waterproofing membranes can be applied in cold weather. However, it is important to consider a few factors when applying these membranes in low temperatures. Cold weather can affect the curing process of the membrane, potentially slowing it down. It is crucial to ensure that the surface being waterproofed is dry and free from ice or frost before applying the membrane. Additionally, some waterproofing products may have specific temperature requirements for optimal performance, so it is essential to consult the manufacturer's guidelines. In colder temperatures, it may also be necessary to use specialized adhesives or primers designed for cold weather applications. Overall, with proper precautions and the use of appropriate materials, waterproofing membranes can be successfully applied in cold weather.

- Q: Can a waterproofing membrane be used in conjunction with fire protection systems?

- Yes, a waterproofing membrane can be used in conjunction with fire protection systems. While the primary function of a waterproofing membrane is to prevent water penetration, it can also act as a barrier to protect against fire. Some waterproofing membranes have fire-resistant properties, allowing them to withstand high temperatures and prevent the spread of fire. However, it is essential to ensure that the specific waterproofing membrane chosen is compatible and approved for use with the fire protection system in question.

- Q: Can a waterproofing membrane be applied on both horizontal and vertical surfaces?

- Yes, a waterproofing membrane can be applied on both horizontal and vertical surfaces. Waterproofing membranes are designed to create a barrier that prevents water from penetrating through surfaces and causing damage. They are commonly used in various applications such as roofs, basements, bathrooms, and swimming pools. Whether it is a horizontal surface like a floor or a vertical surface like a wall, the waterproofing membrane can be applied to provide protection against water infiltration. The application process may vary depending on the specific surface, but there are membranes available that can be easily applied on both horizontal and vertical surfaces. It is important to follow the manufacturer's instructions and consult with professionals to ensure proper installation and effectiveness of the waterproofing membrane.

- Q: What are the requirements for the storage of waterproofing membranes?

- Stand up to release the time can not put too long or how you put the deformation will be ..... so we generally stand

- Q: Can a waterproofing membrane be used on tunnels with subway systems?

- Tunnels with subway systems can indeed benefit from the use of a waterproofing membrane. It is strongly advised to incorporate this protective layer into subway tunnel construction to prevent water infiltration and potential harm to the structure and electrical systems. The waterproofing membrane acts as a barrier, effectively excluding water and safeguarding the tunnel against issues caused by moisture, such as corrosion, mold, and deterioration. It is crucial to select a waterproofing membrane that is specially designed for tunnel use and capable of withstanding the unique challenges and conditions of subway systems, including heavy traffic loads, vibrations, and exposure to chemicals. Moreover, it is essential to ensure the installation of the waterproofing membrane is carried out by experienced professionals who adhere to the appropriate guidelines and specifications, guaranteeing its effectiveness and durability.

- Q: Can a waterproofing membrane be used on gypsum board surfaces?

- Yes, a waterproofing membrane can be used on gypsum board surfaces. Gypsum board, also known as drywall, is a common material used in interior construction. While it is not inherently waterproof, applying a waterproofing membrane can help protect the gypsum board from moisture damage. A waterproofing membrane is a thin layer of material that is applied to the surface of the gypsum board. It forms a barrier that prevents water from seeping into the board and causing it to deteriorate or mold. It can be used in areas where moisture is present, such as bathrooms, kitchens, laundry rooms, or basements. Before applying a waterproofing membrane, it is important to prepare the gypsum board surface properly. This may involve cleaning the surface, patching any holes or cracks, and ensuring the board is dry and free of dust. Once the surface is ready, the waterproofing membrane can be applied according to the manufacturer's instructions. It is worth noting that while a waterproofing membrane can provide some protection against moisture, it is not a guarantee against water damage. It is always important to address the source of water intrusion and ensure proper drainage and ventilation in any area prone to moisture. Additionally, it is recommended to consult with a professional or follow the manufacturer's recommendations when choosing and applying a waterproofing membrane to gypsum board surfaces.

- Q: Can waterproofing membranes be used on concrete manholes?

- Indeed, concrete manholes can benefit from the application of waterproofing membranes. These membranes are widely utilized to safeguard structures against water penetration and can be effectively utilized on various surfaces, including concrete. Given that concrete manholes are susceptible to water ingress, which may result in deterioration and structural problems over time, the application of a waterproofing membrane on the concrete surface of the manhole creates a barrier that prevents water intrusion into the structure. This measure serves to lengthen the lifespan of the manhole and guarantee its structural integrity in the long run. Moreover, in addition to providing protection against chemical attacks and other environmental factors, waterproofing membranes further enhance the durability of concrete manholes.

- Q: Can a waterproofing membrane be used on balconies or decks?

- Balconies or decks can indeed benefit from the use of a waterproofing membrane. These membranes are specifically designed to offer a shield against water and moisture, making them an ideal solution for outdoor spaces that are constantly exposed to the elements. Their composition typically includes rubber, PVC, or bitumen, and they are directly applied to the surface of the balcony or deck. By doing so, they effectively prevent water from penetrating the underlying structure, safeguarding it against potential damage caused by moisture. Waterproofing membranes prove particularly advantageous in areas prone to heavy rainfall, snow, or high humidity, as they effectively prolong the lifespan of the balcony or deck by preventing water-related issues such as rot, mold, or deterioration. Moreover, these membranes also serve as an additional layer of protection against harmful UV rays, effectively preventing discoloration or fading of the balcony or deck surface. Ultimately, opting for a waterproofing membrane for balconies or decks is a wise investment that ensures their durability while maintaining their aesthetic appeal.

- Q: Can a waterproofing membrane be used for a balcony deck?

- Indeed, a balcony deck can be protected by utilizing a waterproofing membrane. It is a highly recommended solution for shielding balcony decks against water damage. The primary purpose of a waterproofing membrane is to establish a barrier that hinders the infiltration of water into the underlying structure. It effectively safeguards the deck from various moisture-related problems such as rot, mold, and deterioration. This membrane is typically applied in either liquid or sheet form, effectively covering the entire surface of the balcony deck to create a seamless and impenetrable layer. Acting as a shield, this membrane ensures that any water coming into contact with the deck is effectively repelled and diverted away. By incorporating a waterproofing membrane, you can successfully prolong the lifespan of your balcony deck and uphold its structural integrity for many years to come.

- Q: Can a waterproofing membrane be used for basements?

- Yes, a waterproofing membrane can be used for basements. In fact, it is one of the most effective solutions for preventing water infiltration and moisture damage in basements. A waterproofing membrane is a thin layer of material that is applied to the exterior walls and/or floors of a basement to create a barrier against water. It is designed to withstand hydrostatic pressure, which is the force exerted by water against the walls and floors. By installing a waterproofing membrane, you can significantly reduce the risk of water damage, mold growth, and structural problems in your basement. It is important to note that proper installation and maintenance of the membrane are crucial for its effectiveness, so it is recommended to consult with a professional waterproofing contractor for the best results.

Send your message to us

Membrane EPDM Vulcanization 1.5mm for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords