EPDM Coiled Rubber Waterproof Membrane with 1.5mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Rubber Waterproof Membrane with 1.5mm Thickness

Description Of EPDM Coiled Rubber Waterproof Membrane with 1.5mm Thickness:

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

Main Features of EPDM Coiled Rubber Waterproof Membrane with 1.5mm Thickness:

A.Polyester based SBS Modified Bitumen Waterproofing Membrane

a. Strong impermeability

b. High tensile strength, elongation, ability to adapt the grassroots shrinkage deformation and cracking

c. Puncture-resistant, broken resistant, tear-resistant

d. The corrosion resistance, resistance to mildew, weathering good

e. Construction convenient, hot-melt can be operated Four Seasons Construction, reliable joints

B. Fiberglass based SBS Modified Bitumen Waterproofing Membrane

a. High tensile strength, stability of a good size

b. High Temperature good performance

c. Damage resistance, corrosion resistance, resistance to mildew, weathering good performance

d. Good construction performance, reliable joints.

Specifications of EPDM Coiled Rubber Waterproof Membrane with 1.5mm Thickness:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Coiled Rubber Waterproof Membrane with 1.5mm Thickness:

1. Roofs, Basement, Toilet

2. Industrial and civil building waterproofing

3. Geo-synthetic liner for swimming pool, channels, irrigation system

4. Especially suit for projects with high requirements in durability, anti-corrosion and deformation

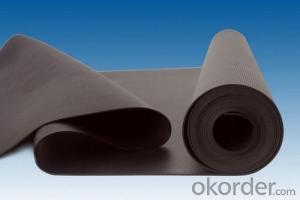

IMages of EPDM Coiled Rubber Waterproof Membrane with 1.5mm Thickness:

FAQ of EPDM Coiled Rubber Waterproof Membrane with 1.5mm Thickness:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Is a waterproofing membrane resistant to algae or moss growth?

- Yes, a waterproofing membrane is typically resistant to algae or moss growth. Waterproofing membranes are designed to create a barrier against water infiltration, preventing moisture from seeping into the underlying structure. These membranes are typically made of materials that are not conducive to the growth of algae or moss, such as synthetic polymers or rubberized compounds. Additionally, waterproofing membranes are often treated with additives that inhibit the growth of organic matter, including algae or moss. However, it is important to note that over time, if the membrane is exposed to constant moisture or damp conditions, it may become a breeding ground for algae or moss. Therefore, regular maintenance and cleaning are important to ensure the longevity and effectiveness of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for wastewater treatment plants or sewage facilities?

- Yes, a waterproofing membrane can be used for wastewater treatment plants or sewage facilities. It helps to prevent water leakage, ensuring the containment and proper treatment of wastewater or sewage.

- Q: Are waterproofing membranes resistant to mineral oils?

- Waterproofing membranes can vary in their resistance to mineral oils. Some waterproofing membranes are specifically designed to be resistant to mineral oils, while others may not be. It is important to check the specifications and product information provided by the manufacturer to determine the resistance of a particular waterproofing membrane to mineral oils. Additionally, it is recommended to consult with a professional or the manufacturer directly for specific guidance on the compatibility of a waterproofing membrane with mineral oils in your specific application.

- Q: Can a waterproofing membrane prevent mold and mildew growth?

- Yes, a waterproofing membrane can help prevent mold and mildew growth. Mold and mildew thrive in damp and moist environments, and waterproofing membranes create a barrier that prevents water from seeping into the underlying surfaces. By keeping the area dry, the membrane reduces the conditions necessary for mold and mildew to grow. Additionally, some waterproofing membranes are designed with antimicrobial properties, which further inhibit the growth of mold and mildew. However, it is important to note that while a waterproofing membrane can help prevent mold and mildew growth, it is not a foolproof solution. Proper ventilation and maintenance are also crucial in preventing these issues.

- Q: Can a waterproofing membrane be used on elevator shafts?

- Yes, a waterproofing membrane can be used on elevator shafts. Elevator shafts are vulnerable to water infiltration, and using a waterproofing membrane can help prevent water damage and leakage into the shaft.

- Q: Is the waterproofing membrane an insulating material?

- There are many varieties of coil, the vast majority of the coil itself is insulated, mainly refers to the rubber, resin, asphalt. But the following are non-insulated: 1, PSS metal waterproofing membrane, which is the only coil in the whole metal coil, but the strict sense should not be included in the waterproofing membrane;

- Q: The difference between waterproof linoleum and waterproofing membrane

- `Linoleum is a kind of waterproofing membrane! Belong to subordinate relationship. Felt is made of animal hair or plant fiber made of carpets or thick paper impregnated asphalt after the building materials, toughness, impermeable, used to do the roof, basement walls, foundations such as waterproof, moisture-proof layer. Also called oil felt. Approximately 2000 years ago, the most commonly used building waterproof material, has now been included in the scope of national banned building materials. At present, the construction of waterproofing membrane is large "elastomer modified asphalt waterproofing membrane" - the implementation of standards for the GB 18242-2008.

- Q: Can waterproofing membranes be used on concrete countertops?

- Yes, waterproofing membranes can be used on concrete countertops. These membranes are designed to create a barrier that prevents water from seeping into the concrete, protecting it from damage and increasing its lifespan.

- Q: What is the PEDM waterproofing membrane material?

- EPDM waterproofing membrane (EPDM) is the main material with ethylene propylene rubber, adding anti-aging agent, accelerator, and adding nano-materials, so that the waterproof membrane weather resistance, heat resistance, low temperature resistance has greatly improved

- Q: Can a waterproofing membrane be used on gypsum block surfaces?

- Yes, a waterproofing membrane can be used on gypsum block surfaces. Gypsum blocks are porous and can be prone to moisture infiltration, so applying a waterproofing membrane can help prevent water damage and moisture-related issues.

Send your message to us

EPDM Coiled Rubber Waterproof Membrane with 1.5mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords