Engravable Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

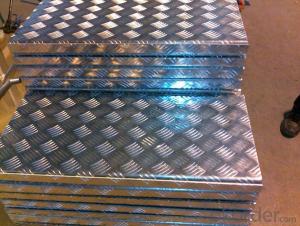

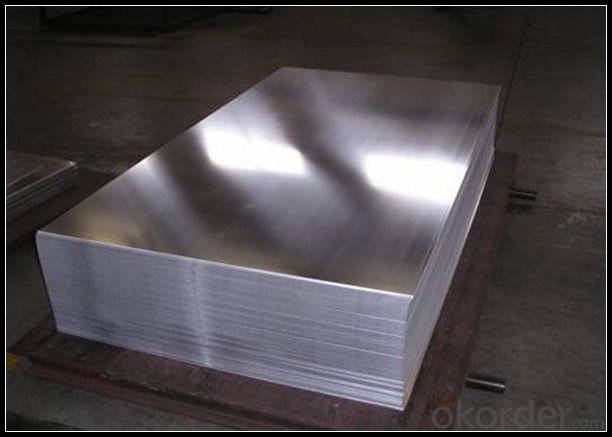

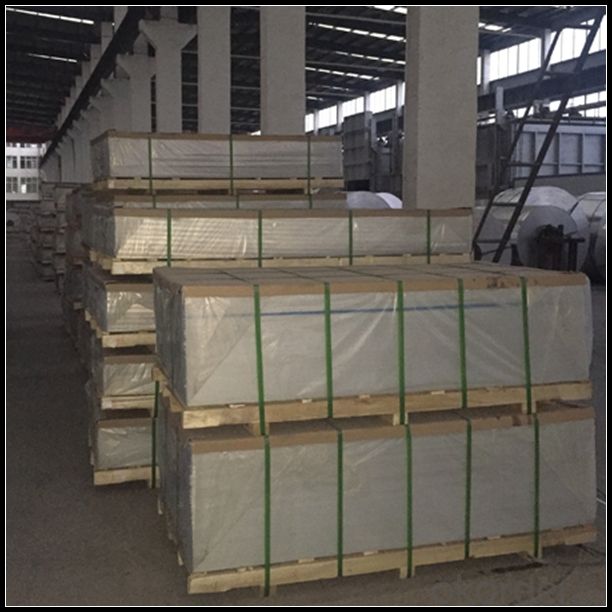

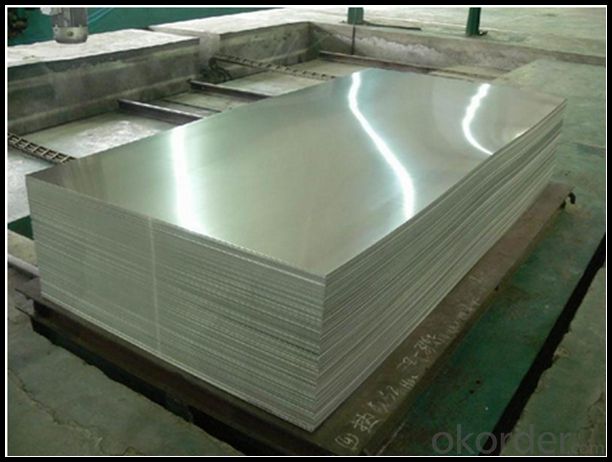

5. Image of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

6. Package and shipping of Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for outdoor uses like fences or signs?

- <p>Yes, aluminum sheets are commonly used for outdoor applications such as fences and signage. Aluminum is lightweight, durable, and resistant to corrosion, making it ideal for outdoor conditions. It can withstand various weather elements without rusting. Additionally, aluminum can be easily formed into different shapes and sizes, and it's available in a wide range of colors and finishes, which makes it versatile for both functional and aesthetic purposes in outdoor settings.</p>

- Q: ... initial temperature of the water or the initial temperature of the aluminum? Why?

- Let's say the aluminum starts out at a higher temperature than the water. The aluminum cools down by 1°C, which means it loses energy (Q = mcΔT, where ΔT = 1°C). That energy goes to the water, warming it up. Since Q is the same for both water and aluminum, and m is the same for both, all that matters is the heat capacity c. Water has a higher heat capacity than aluminum, so for the same Q it must have a smaller ΔT. This process continues until both have reached the same T. From the above paragraph, you should be able to figure out if the final T is closer to the initial water temp or the original aluminum temp.

- Q: I have an aluminum block engine in my wakeboard boat which is built for the lakes, now i live on salt water and was wondering the effect saltwater would have on the engine block as water goes through to cool it.

- Munch Munch better flush when done.

- Q: Can aluminum sheets be used for protective enclosures?

- Aluminum sheets have the ability to be utilized for protective enclosures. This material, known for its versatility and lightweight nature, offers exceptional durability and resistance to corrosion. It can easily be transformed into various shapes and sizes, making it suitable for constructing protective enclosures across a wide range of applications. Industries such as electronics, telecommunications, aerospace, and automotive commonly employ aluminum enclosures, which safeguard against environmental factors like moisture, dust, and electromagnetic interference. Moreover, these enclosures can be further improved with the addition of coatings or insulation materials to meet specific requirements for thermal insulation, fire resistance, or electrical conductivity. All in all, aluminum sheets are a dependable option for protective enclosures due to their strength, adaptability, and capacity to endure challenging conditions.

- Q: Are aluminum sheets suitable for water storage applications?

- Yes, aluminum sheets are suitable for water storage applications. Aluminum is a corrosion-resistant material and does not rust, making it ideal for storing water without any negative impact on its quality. Additionally, aluminum sheets are lightweight, durable, and easily moldable, allowing for the construction of various water storage containers and tanks.

- Q: What is the cost of aluminum sheet compared to other metals?

- The cost of aluminum sheet compared to other metals can vary depending on various factors such as market conditions, availability, and specific metal grades. Generally, aluminum sheet is considered to be more affordable than many other metals such as stainless steel, copper, and brass. This is mainly due to the abundance of aluminum in the Earth's crust and the relatively low cost of extracting and refining it. Additionally, aluminum is often lighter in weight compared to other metals, making it a more cost-effective option for applications where weight is a concern, such as in the transportation industry. However, it is important to note that the cost of aluminum can fluctuate based on global supply and demand dynamics, tariffs, and other economic factors. Therefore, it is recommended to check current market prices and consult with suppliers or metal specialists for accurate and up-to-date pricing information.

- Q: Are aluminum sheets suitable for aerospace wing structures?

- Yes, aluminum sheets are suitable for aerospace wing structures. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and its ability to withstand high temperatures. Aluminum alloys, such as 2024 and 7075, are commonly used for wing structures as they provide high strength and durability. Additionally, aluminum can be easily formed into different shapes and sizes, allowing for the production of complex wing designs. Overall, aluminum sheets offer a combination of lightweight properties, strength, and reliability, making them highly suitable for aerospace wing structures.

- Q: How do you ensure the flatness of large aluminum sheets?

- To guarantee the flatness of large aluminum sheets, there are several essential measures that can be taken: 1. Choosing the right material: Begin by selecting top-quality aluminum sheets that are specifically designed for flatness. These sheets should have a consistent thickness and minimal internal stress to minimize the risk of warping. 2. Proper storage: Store the aluminum sheets in a controlled environment to prevent exposure to extreme temperature changes or humidity. This will help prevent any potential expansion or contraction of the metal, which can result in warping. 3. Handling and transportation: When moving or transporting the aluminum sheets, ensure that they are evenly supported to avoid any bending or flexing. Use appropriate lifting and handling equipment to avoid putting excessive strain on the sheets. 4. Machining and processing: During the machining and processing stages, it is crucial to employ proper techniques and equipment to maintain flatness. Utilize precision machinery that can handle large sheets and has features to minimize distortion or bending during cutting, drilling, or forming processes. 5. Heat treatment: If necessary, heat treatment can be used to relieve any residual stress in the aluminum sheets. Thermal stress relief techniques, like annealing, can help reduce internal stress and enhance flatness. 6. Quality control: Implement a rigorous quality control procedure to ensure the flatness of the aluminum sheets. This can involve regular inspections using precision measuring instruments, such as straightedges or laser scanners, to identify any deviations from flatness. If any issues are detected, corrective actions can be taken promptly. By following these steps, manufacturers can guarantee the flatness of large aluminum sheets, a critical requirement for industries such as aerospace, automotive, construction, and manufacturing.

- Q: Aluminum does not react with oxygen.Aluminum is a very unreactive metal.Aluminum forms a tough protective coating with oxygen.Aluminum tarnishes instead of corroding.If you could explain why it would be helpful!

- Aluminum forms a tough protective coating with oxygen. The coating of aluminum oxide is not porous enough to let further oxygen through it, so the aluminum underneath is protected from further corrosion.

- Q: (2) when aluminium foil is dipped in mercury for a short time and then placed in water a reaction is seen to occur with hydrogen gas being one of the products.?????

- Aluminium is very reactive in air and forms a protective oxide coating. This protects it when placed in water as aluminium oxide is unreactive with water. When immersed in mercury the oxide coating is removed and therefore the aluminium itself reacts when the cleaned aluminium metal is immersed in water.

Send your message to us

Engravable Checkered Aluminium Sheets AA3005 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords