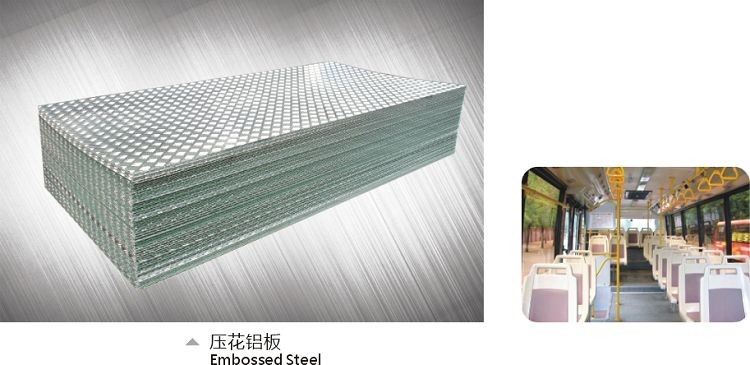

Embossed Number 4 Brushed Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Orange Peel Embossed Aluminum Sheet

1.alloy: 1100,3003

2.stucco embossed.

3.width:100-1500mm

4.length:20-6000mm

1) Aluminum Alloy:1100,3003 in a range of standard and custom temper

2) Coating: PE paint, PVDF paint

3) Thickness: 0.026- 1.0mm

4) Width: 50 - 1500mm

5) Coil Inner Diameter: 505mm,405mm

6) Various colors are available. We also can make in accordance with your own color swacth

7) Suitable to construction curtain walls, ceilings, store faces, walls and cellular panels

8) We can cut the coil to sheet,strip upon your request.

- Q: I have an aluminum block engine in my wakeboard boat which is built for the lakes, now i live on salt water and was wondering the effect saltwater would have on the engine block as water goes through to cool it.

- Munch Munch better flush when done.

- Q: What is the typical shear strength of aluminum sheets?

- The typical shear strength of aluminum sheets can vary depending on various factors such as the alloy, temper, thickness, and manufacturing process. However, for most common aluminum alloys, the typical shear strength falls within the range of 207 to 310 megapascals (MPa) or 30,000 to 45,000 pounds per square inch (psi). It is important to note that these values are just general guidelines and there can be variations depending on the specific application and conditions. For critical applications, it is recommended to consult the material specifications or seek professional advice to determine the precise shear strength requirements for the specific aluminum sheet being used.

- Q: I'm making a project for class and I bought a 10 Inch long 5mm thick aluminum/metal, How do you cut it WITHOUT large machinery? is there any power tools adapters or tools that can do this job without a problem?Here is what I have to do:*Cut the metal into ~1x1 and 2X2inch squares*Somehow shave a circle about 2mm deep without going trough the 5mm aluminum (Shaded gray)*Drill a hole right through the 5mm (right in the center)*Drill screw holes on each cornerI provided a really basic pic of what I'm trying to dohttp://img204.imageshack.us/img204/487/77845398.pngRED=backgroundGRAY=drilled 2mm deep WITHOUT GOING THROUGHRED HOLES=screw holes with threadsPlz help need to finish this by friday!PS: Screw holes, and other sizes don't matter right now I'm just trying to figure out what tools/tool adapters I need thanks!

- A rotary tool may do the trick. You would have to have a steady hand and also be able to hold the aluminum securely in place.

- Q: This question asks for a guide on the correct procedure to install aluminum sheets, likely for construction or renovation purposes.

- <p>To install aluminum sheets properly, follow these steps: 1. Prepare the surface by cleaning and leveling it. 2. Measure and cut the aluminum sheets to the required size using a metal saw or tin snips. 3. Apply a bead of construction adhesive along the edges of the surface where the sheets will be placed. 4. Position the aluminum sheet, ensuring it's aligned correctly. 5. Secure the sheet with screws or nails, using a washer to prevent tearing. 6. Seal the seams and edges with a weatherproof sealant to prevent water ingress. 7. Inspect the installation for any gaps or unevenness and make adjustments as needed. Always follow the manufacturer's guidelines and safety precautions while working with aluminum sheets.</p>

- Q: How do aluminum sheets perform in terms of formability?

- Aluminum sheets are highly formable due to their low density and high malleability. They can be easily shaped into various forms and are commonly used in industries such as automotive, aerospace, and construction for their excellent formability properties.

- Q: What is the thickness range available for aluminum sheets?

- The thickness range available for aluminum sheets typically varies from 0.006 inches (0.15mm) to 0.25 inches (6.35mm), depending on the specific requirements and application.

- Q: What are the methods to protect aluminum sheets from corrosion during their usage?

- <p>To prevent corrosion of aluminum sheets during use, several strategies can be employed. First, apply a protective coating such as paint, anodizing, or a conversion coating to create a barrier against corrosive elements. Second, ensure proper cleaning and drying to avoid the accumulation of moisture and contaminants. Third, use corrosion inhibitors in environments where aluminum is exposed to aggressive chemicals. Fourth, maintain good ventilation to reduce humidity levels. Finally, regularly inspect and maintain the aluminum sheets to address any signs of corrosion early. These measures can significantly extend the lifespan and performance of aluminum sheets.</p>

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- In the long run you will find it is much cheaper to use carbon arrows even though the initial cost of them is higher then aluminum. And don't be frightened by the videos of carbon arrows breaking when shooting them. The odds of lightning striking you would be about the same. In most incidences of arrow breakage when being shot, it was with a heavy draw compound and using carbon arrows that were much too light weight to be shot from a bow that they were not designed to be shot from. People sometimes use the lightest weight carbon arrows they can find to make their bow shoot faster then anyone Else's. Sometimes they pay a price for it.

- Q: what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- general horizontal driving sawing and precision sawing.

- Q: What are the advantages of using aluminum sheets?

- Some advantages of using aluminum sheets include their lightweight nature, corrosion resistance, and high strength-to-weight ratio. Aluminum sheets are also highly malleable, making them easy to form into various shapes and sizes. Additionally, aluminum is a highly recyclable material, making it more environmentally friendly compared to other metals.

Send your message to us

Embossed Number 4 Brushed Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords