Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet

Quick Details

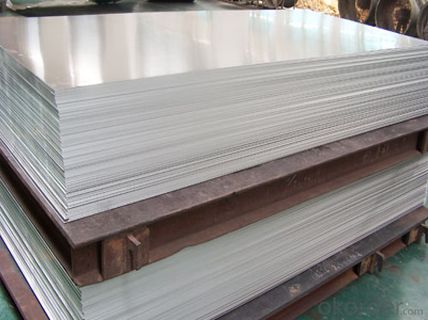

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DC51D+AZ,DX51D+AZ,SGLCC

Thickness: 0.13mm--3.0mm

Model Number:DC51D+AZ,DX51D+AZ,SGLCC

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized, Chromated, Oiled, Anti-finger Print

Application: Architecture,Auto Industry,Appliances Industry,Industrial Instruments

Width: 600mm--1250mm

Length: Any Length Based on Coil Weight or by Required

Product Name: Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet

Key Word: Aluzinc 1.5mm

Spangle: Mini Spangle

Thickness of coating: AZ30--AZ150

Coil I.D.: 508/610mm

Coil Weight: 3--10MT

Supply Ability: 700,000 MT per Year

Substrate Steel: Cold Rolled

Steel Grade:DC51D+AZ,DX51D+AZ,SGLCC

Pack and Delivery

| Packaging Details: | Mill's Standard Export Sea-worthy Packing for Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet |

|---|---|

| Delivery Detail: | 15~30 Days for Electrical Cabinet Making Aluzinc 1.5mm Steel |

FAQ

1.Q: Do you have the Galvalume Steel Coils in stock?

A: We have Galvalume Steel Coils in stock ,also can produce according to your order.

2.Q: Are you professional at your products?

A: have over 10-year experience on service end-user and knows well about characters and usage of material, professional suggestion about products can be offered when you needed.

Picture

- Q: Hello,is it possible to divide an alloy in its own elements? I am particularly interested in Stainless Steel, which is made of Nickel, Chrome and Iron. Do you have an idea of where can I find some more information (blogs, reviews, sites or books)?Thanks for your help

- All you have to do is heat the alloy. Since an alloy is a physical mixture heating will be able to separate the different elements according to their melting point. All elements have their own unique melting point.

- Q: Is it possible to have a 25 room Hotel building with Steel structure. Thay is instead of traditional RCC can we have a 25 room hotel constructed using steel construction? Is it economic and how much time will it take to construct the same? Appraximate area would be 5000sq.ft to 10000sqft.

- Yes you can have a steel structure building, as if it is more economical than RCC, I think it is , and it is much faster in completion than RCC, For such area steel structure is less in time than the RCC by 30% to 40%, my experience could estimate 6months to 8 months duration for steel structure

- Q: How do steel coil manufacturers ensure timely delivery?

- Timely delivery is ensured by steel coil manufacturers through a variety of strategies and measures. Their first priority is to maintain a well-coordinated system for production and supply chain management. This involves efficiently scheduling production processes, monitoring inventory levels, and closely coordinating with raw material suppliers. In addition, advanced forecasting techniques are often employed by steel coil manufacturers to predict product demand. By analyzing historical data, market trends, and customer behavior, they can anticipate future orders and plan production accordingly. This proactive approach minimizes the risk of delays and allows for better allocation of resources. Furthermore, close collaboration with transportation and logistics companies is essential to ensure smooth and timely delivery. Strategic partnerships are established and favorable agreements negotiated to facilitate efficient transportation of steel coils to customers. This includes optimizing routes, utilizing reliable carriers, and closely tracking shipments to promptly address any unforeseen issues. Moreover, buffer stocks may be maintained by manufacturers to mitigate the impact of unexpected disruptions, such as equipment failures or supplier delays. By having a safety stock of finished products, they can quickly respond to urgent orders and uphold their delivery commitments. Lastly, effective communication plays a crucial role in ensuring timely delivery. Steel coil manufacturers maintain open lines of communication with their customers, keeping them informed about production progress and potential delays. This transparency allows for proactive problem-solving and helps manage customer expectations. In conclusion, steel coil manufacturers employ efficient production and supply chain management systems, advanced forecasting techniques, collaboration with transportation and logistics companies, buffer stocks, and effective communication to ensure timely delivery. These strategies collectively enable them to meet delivery deadlines and provide reliable service to their customers.

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through a process known as galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing the steel from coming into direct contact with moisture and oxygen, which are the main causes of corrosion. Additionally, other protective measures such as painting or coating the steel with anti-corrosion materials may also be employed to further enhance its resistance against corrosion.

- Q: the difference between the original steel and mild steel from percentage of carbon

- As the first answers suggest, the prolbem is that these terms are not specific, they are not scientifically or technically defined. This is like asking: what is the difference between a four door car and a sedan? There are hundreds of steel alloys ranging from Fe + a little C + very little else to alloy and tool steels with significant amounts of Cr, Ni, Si, and a number of other elements + C. And... for any given steel alloy, there are many different ways to heat treat it. A given piece of steel can be heat treated so hard and brittle that it could shatter like glass and then it could be heat treated to make it into a spring or heat treated to make it stretch like taffy. If you really want to understand steels, yes, there are lots of books on sword making (some written by people who actually understand steels) but... you need to study metallurgy. There are graduate level courses just on the metallurgy of steels. Of course to understand this course you need to understand a whole lot of fundamental metallurgy. All this stuff on steel makes perfect sense because, in terms of weight (tonage) produced, steel is, hands down, nothing else remotely comes close, the most important metal humans have.

- Q: How long does the coating on steel coils last?

- The longevity of the coating on steel coils depends on various factors such as the type of coating used, the environmental conditions it is exposed to, and the maintenance practices. However, on average, a well-applied coating can last anywhere from 10 to 20 years before requiring reapplication or maintenance.

- Q: How do steel coils contribute to energy savings in buildings?

- Steel coils contribute to energy savings in buildings in several ways. Firstly, steel coils are often used as part of the insulation system in buildings. The high thermal conductivity of steel allows for efficient heat transfer, ensuring that the building remains well-insulated and energy loss is minimized. Additionally, steel coils are often used for HVAC systems, which play a crucial role in energy efficiency. By using steel coils in these systems, the heat transfer process can be optimized, reducing the energy required to heat or cool the building. Moreover, steel coils are durable and long-lasting, reducing the need for frequent replacements and maintenance, which in turn saves energy and resources. Overall, the use of steel coils in buildings helps to improve energy efficiency and reduce energy consumption, contributing to significant energy savings.

- Q: How do steel coils contribute to the manufacturing of HVAC systems?

- The manufacturing of HVAC systems heavily relies on steel coils, which have a critical role. These coils typically consist of high-quality steel, known for its exceptional strength, durability, and resistance to heat. Heat exchangers are one of the primary applications of steel coils in HVAC systems. These exchangers play a vital role in transferring heat between different mediums, usually air and a refrigerant. In HVAC systems, steel coils are employed in both the evaporator and condenser coils. The evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the external environment. These coils are designed with numerous coiled tubes connected by fins. The use of steel in their construction ensures their ability to withstand high pressure and resist corrosion, guaranteeing the long-term reliability and efficiency of the HVAC system. Steel coils also contribute to the overall structural integrity of HVAC systems. They are commonly utilized in the fabrication of ductwork, responsible for distributing conditioned air throughout a building. The strength and rigidity of steel coils enable the ductwork to maintain its shape and structural integrity under various conditions, including high air pressure and temperature fluctuations. Additionally, steel coils are frequently involved in the fabrication of HVAC system cabinets and enclosures. These cabinets house several system components, including compressors, fans, and control panels. The robustness of steel coils ensures that the cabinets can withstand external forces, protect the internal components, and provide a secure housing for the entire HVAC system. To summarize, steel coils are crucial components in the manufacturing of HVAC systems. Their strength, durability, and heat resistance make them ideal for applications such as heat exchangers, ductwork, cabinets, and enclosures. By incorporating steel coils, HVAC manufacturers can produce systems that efficiently regulate temperature, enhance indoor air quality, and provide comfort in various residential, commercial, and industrial settings.

- Q: Apparently, this has to do something with electrochemical cells.

- Steel wood? I don't think there is such a thing?

- Q: What are the common welding methods used for steel coils?

- There are several common welding methods used for steel coils, depending on the specific requirements and applications. Some of the most widely used methods include: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW uses an electrode coated in flux to create an arc between the electrode and the base metal. This method is commonly used for its simplicity and versatility, making it suitable for a wide range of steel coil welding applications. 2. Gas Metal Arc Welding (GMAW): Also known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. This method is favored for its high welding speed and excellent control over the welding process. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuously fed tubular electrode filled with flux to protect the weld pool. This method is often preferred for its high deposition rates and ability to weld thicker steel coils, making it ideal for heavy-duty applications. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode and an inert gas shield to protect the weld pool. This method is commonly used for its precise control, high-quality welds, and ability to weld thin materials. 5. Submerged Arc Welding (SAW): SAW involves the formation of an arc between a continuously fed wire electrode and the steel coil, while a granular flux covers the arc and weld area. This method is frequently used for its high productivity and ability to weld thick materials. Each of these welding methods has its own advantages and limitations, and the choice of method depends on factors such as the thickness of the steel coil, desired welding speed, weld quality, and application requirements.

Send your message to us

Electrical Cabinet Making Aluzinc 1.5mm Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords