Aluzinc steel sheet building material composed of sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ALUZINC Steel Sheet is carbon steel sheet coated with aluminum-zinc alloy by a continuous hot-dip

process. The nominal coating composition is 55% aluminum and 45% zinc. A small but important addition

of silicon is included in the coating alloy. It is added not to enhance the corrosion performance, but to

provide good coating adhesion to the steel substrate when the product is roll-formed, drawn, or bent during

fabrication.

While Galvalume has excellent durability in many settings, it should not be used adjacent to concrete or mortar.

Due to the high alkaline content in these environments, bare and painted Galvalume rapidly corrode.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Packaging & Shipping

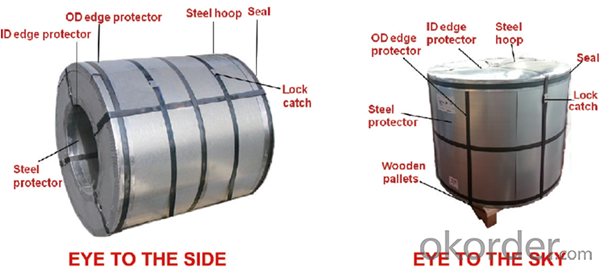

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: Can steel sheets be used for bridge construction or infrastructure projects?

- Bridge construction and infrastructure projects can utilize steel sheets. The popularity of steel in these applications stems from its exceptional strength, durability, and versatility. Depending on project requirements, steel sheets can be utilized in various forms, including hot-rolled, cold-rolled, or galvanized. Steel sheets provide numerous advantages for bridge construction and infrastructure projects. Firstly, they possess a high load-bearing capacity, enabling them to support heavy loads and uphold the structural integrity of bridges and infrastructure. Steel also exhibits a high tensile strength, allowing it to endure significant stress and deformation without failure. Furthermore, steel sheets are easily fabricated into different shapes and sizes, granting designers flexibility for innovative and efficient structures that meet specific project needs. Steel's recyclability renders it an environmentally friendly option for sustainable infrastructure projects. Additionally, steel sheets display excellent resistance to corrosion, a crucial attribute for infrastructure projects exposed to harsh environments like bridges near saltwater or industrial areas. By using galvanized steel sheets, their corrosion resistance can be further enhanced, ensuring long-term durability and reduced maintenance requirements. In conclusion, steel sheets are a dependable and extensively utilized material for bridge construction and infrastructure projects. Their strength, durability, flexibility, and corrosion resistance make them an ideal choice for ensuring the safety and longevity of these vital structures.

- Q: Can the steel sheets be used for insulation purposes?

- No, steel sheets are not typically used for insulation purposes. Steel is a highly conductive material, meaning it transfers heat and cold very easily. This makes it unsuitable for insulation, as it would not effectively prevent the transfer of thermal energy. Insulation materials, on the other hand, are specifically designed to reduce heat transfer and improve energy efficiency in buildings and other structures. Common insulation materials include foam, fiberglass, and cellulose, which have much higher resistance to heat flow compared to steel.

- Q: What is the acoustic insulation performance of steel sheets?

- The acoustic insulation performance of steel sheets is generally low. Steel is a dense and rigid material that does not provide much soundproofing or noise reduction. However, the acoustic insulation can be improved by using specialized techniques such as adding layers of acoustic insulation materials or incorporating sound-absorbing panels in the construction.

- Q: How can steel plates with a thickness of 1MM be welded?

- Spot welding is the welding joints in the contact surface of the individual points are welded together. The metal spot welding have better ductility. When welding, the welding surface is clean, then by sheet lap welding assembly, pressure between two cylindrical copper electrode, pressing force applied by means of the current. Large enough, resulting in a large number of heat resistance at the contact plate, the center of the hottest areas of the metals quickly heated to high plasticity or melting state, the molten pool formed a lens shaped. To keep the pressure off the current, the metal cools, forming a solder joint.

- Q: What is the difference between a corrugated and flat steel sheet?

- The structural design is the main distinction between a corrugated steel sheet and a flat steel sheet. A corrugated sheet has a wavy pattern formed by parallel ridges and grooves, which adds strength and rigidity. This makes it suitable for applications that need to bear heavy loads. Furthermore, the ridges in a corrugated sheet enhance its resistance to bending and impact, making it a popular choice for roofing and siding. On the other hand, a flat steel sheet lacks ridges or grooves and has a smooth, flat surface. This design allows for more flexibility and easy fabrication into different shapes and sizes. Flat steel sheets are commonly used in applications that require a smooth and even surface, such as automotive body panels, appliances, and fabrication projects. In terms of appearance, corrugated steel sheets have a distinct and textured look due to their wavy pattern, while flat steel sheets have a sleek and uniform appearance. In summary, the choice between a corrugated and flat steel sheet depends on the specific application and desired characteristics. If enhanced strength and load-bearing capabilities are needed, a corrugated sheet would be preferred. However, if versatility and ease of fabrication are important, a flat steel sheet would be the more suitable option.

- Q: What is the typical weight of steel sheets?

- The typical weight of steel sheets can vary depending on the thickness and dimensions of the sheet. However, a commonly used gauge for steel sheets is 16 gauge, which typically weighs around 40 to 50 pounds per square foot.

- Q: What is the process of applying protective coatings to steel sheets?

- The process of applying protective coatings to steel sheets typically involves several steps. First, the steel sheets are thoroughly cleaned and prepared to ensure a clean and smooth surface. This may involve removing any existing rust, dirt, or contaminants. Next, a primer or base coat is applied to the steel sheets. The primer helps to promote adhesion between the steel surface and the protective coating. It also provides additional corrosion resistance. After the primer has dried, the main protective coating is applied. This coating can vary depending on the specific requirements and intended use of the steel sheets. Common types of protective coatings for steel include epoxy, polyurethane, or powder coatings. The coating is carefully applied to ensure an even and consistent coverage. Once the protective coating has been applied, the steel sheets are typically cured or dried according to the manufacturer's instructions. This allows the coating to fully bond and harden, increasing its durability and resistance to corrosion. Overall, the process of applying protective coatings to steel sheets involves cleaning and preparing the surface, applying a primer, applying the main protective coating, and properly curing or drying the coating to ensure optimal performance.

- Q: What are the different surface patterns available for steel sheets?

- There are several different surface patterns available for steel sheets, including smooth, diamond, stucco, and textured patterns.

- Q: Are steel sheets suitable for HVAC equipment?

- Yes, steel sheets are suitable for HVAC equipment. Steel is a durable and strong material that can withstand high temperatures, resist corrosion, and provide structural support. It is commonly used in the construction of HVAC systems, such as ductwork, air handlers, and exhaust systems, due to its excellent mechanical properties and ability to meet the demands of the HVAC industry.

- Q: How are steel sheets protected against rusting?

- Corrosion protection is employed to safeguard steel sheets against rusting. Several techniques are utilized for this purpose: 1. Galvanization: Zinc is applied as a coating on the steel sheets. Acting as a sacrificial anode, the zinc corrodes in lieu of the steel when exposed to moisture or oxygen. Consequently, a barrier is formed to shield the steel from rust. 2. Painting: A layer of paint is applied to the steel sheets, creating a protective barrier against moisture and oxygen. This physical barrier prevents contact between these elements and the steel, thus reducing the likelihood of rust formation. 3. Powder coating: Dry powder is spread onto the steel sheets and then heated to establish a protective layer. The powder liquefies and fuses into a smooth coating, offering remarkable resistance to rust and corrosion. 4. Electroplating: The steel sheets are immersed in a bath containing a metal coating solution, such as zinc or chromium. By passing an electric current through the bath, the metal coating bonds with the steel, serving as a safeguard against rust. 5. Phosphating: A chemical process deposits a layer of zinc or manganese phosphate onto the steel sheets. This layer enhances the adhesion of paint or other coatings, providing a surface resistant to corrosion. These techniques find widespread usage in various industries to avert the rusting of steel sheets. The selection of a specific method is contingent upon factors such as cost, durability requirements, and the intended environment for the steel sheets.

Send your message to us

Aluzinc steel sheet building material composed of sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords