Fiberglass Mat Tissue E Glass Woven Roving Fabric for Hand Layup and Robot Process

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

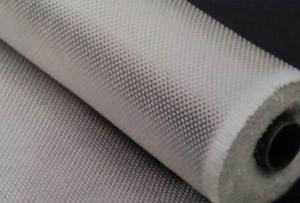

Fiber Glass Woven Roving Fabrics are bidirectional fabric made by interweaving direct rovings.

Fiber Glass Woven Roving Fabrics are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

Fiber Glass Woven Roving Fabrics are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

2.Product Features

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Densely aligned fibers, resulting in high dimensional stability and making handling easy

Good mechanical properties and high strength of parts

3.Product Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

Special specification can be produce according to customer requirements.

4.FAQ

4.FAQ

Storage:

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

Payment term:

The payment term can be T/T in advance or L/C.The products will be ready in 20 days after getting the payment or L/C.

- Q: How does the roll diameter of fiberglass mat tissue affect its handling?

- The roll diameter of fiberglass mat tissue can have a significant impact on its handling. A larger roll diameter generally means a heavier and bulkier roll, making it more challenging to handle and maneuver. This can be particularly important in situations where the fiberglass mat tissue needs to be transported or installed manually. A larger roll diameter may also require more physical effort to lift and move, which can lead to increased strain on the individuals handling it. Moreover, larger roll diameters can also take up more space, making storage and transportation more cumbersome. On the other hand, a smaller roll diameter can make the fiberglass mat tissue easier to handle, as it is lighter and more compact. This can be particularly advantageous in situations where frequent movement and installation are required, such as in construction sites or manufacturing facilities. Additionally, a smaller roll diameter may allow for more efficient storage and transportation, as it takes up less space and can be stacked more easily. This can help optimize logistics and minimize costs associated with storage and transportation. Overall, the roll diameter of fiberglass mat tissue directly affects its handling characteristics, with larger diameters making it more challenging to handle and smaller diameters providing easier handling and improved storage efficiency.

- Q: Can fiberglass mat tissue be used for making lightweight panels?

- Yes, fiberglass mat tissue can be used for making lightweight panels. Fiberglass mat tissue is a thin and lightweight material made from fine glass fibers, which are bonded together with a resinous binder. This material is commonly used in the construction industry to reinforce surfaces and provide strength to various applications. When used in panel manufacturing, fiberglass mat tissue can be an excellent choice for producing lightweight panels. The thin and flexible nature of the material allows it to be easily incorporated into panels without adding significant weight. Additionally, fiberglass mat tissue has excellent strength properties, which can contribute to the overall structural integrity of the panels. Furthermore, fiberglass mat tissue can provide insulation and soundproofing properties to the panels, making them suitable for applications where these characteristics are required. The material is also resistant to corrosion and moisture, which enhances the durability and longevity of the panels. Overall, fiberglass mat tissue is a versatile and lightweight material that can be effectively used for making lightweight panels. Its strength, flexibility, insulation properties, and resistance to corrosion and moisture make it a suitable choice for various applications in industries such as construction, automotive, aerospace, and marine.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. Fiberglass mat tissue is a lightweight and durable material that is commonly used in various industries, including wind energy. It is highly suitable for wind turbine nacelles due to its excellent mechanical properties, such as high strength, stiffness, and resistance to corrosion and fatigue. Additionally, fiberglass mat tissue can be easily molded into complex shapes, making it ideal for fabricating the intricate components of wind turbine nacelles. Overall, using fiberglass mat tissue in wind turbine nacelles helps to enhance their structural integrity, reduce weight, and improve the overall performance and longevity of the turbines.

- Q: Can fiberglass mat tissue be used for making fiberglass molds?

- Fiberglass molds can be made using fiberglass mat tissue. This lightweight material is composed of randomly oriented fiberglass strands and is commonly utilized in composite manufacturing to reinforce fiberglass laminates and enhance their strength. For the production of fiberglass molds, the mat tissue can be employed as a surface layer to achieve a smooth and durable finish. Its application helps prevent the formation of air bubbles, increases the mold's overall strength, and provides a suitable surface for the use of release agents or gel coats. Nevertheless, it is important to acknowledge that relying solely on fiberglass mat tissue may not be enough to create a sturdy and long-lasting mold. It is often combined with other fiberglass materials, such as chopped strand mat or woven roving, to bolster the mold's strength and thickness. In summary, fiberglass mat tissue can be a valuable component in the production of fiberglass molds, but it is typically utilized in conjunction with other materials to attain the desired properties.

- Q: How long does fiberglass mat tissue typically last?

- The duration of fiberglass mat tissue's lifespan is subject to fluctuation due to a variety of factors, including material quality, exposure to environmental conditions, and maintenance level. Typically, fiberglass mat tissue has a lifespan of 20 to 30 years. Nevertheless, by implementing appropriate installation techniques and consistent maintenance practices, it has the potential to endure beyond this time frame. It is crucial to emphasize that routine inspections and maintenance aid in the detection of any indications of deterioration or harm, permitting prompt repairs or replacements to guarantee its longevity.

- Q: Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Indeed, fiberglass mat tissue proves to be a suitable option for insulation within chemical processing plants. Comprised of delicate glass fibers securely bonded with a binder, it possesses remarkable thermal insulation characteristics. Its capability to endure elevated temperatures and its resistance against numerous chemicals render it an ideal selection for deployment in chemical processing plants, where contact with corrosive substances or intense heat may occur. Moreover, fiberglass mat tissue is lightweight and effortlessly installed, presenting a cost-effective solution for insulation in such industrial settings.

- Q: Is fiberglass mat tissue suitable for chemical storage tanks?

- Chemical storage tanks often find fiberglass mat tissue to be a suitable choice. The chemical resistance properties of fiberglass itself are well-known, which is why it is commonly used for storing a wide variety of chemicals. Moreover, fiberglass mat tissue is typically employed as a reinforcement layer during the construction of fiberglass tanks, providing them with added strength and durability. Nevertheless, it is important to consider the specific chemical being stored. Certain highly corrosive or reactive chemicals may necessitate the use of more specialized materials or additional protective coatings to ensure the tank's integrity. Therefore, it is always advisable to seek guidance from a professional engineer or manufacturer in order to identify the most appropriate materials for a given chemical storage application.

- Q: What are the different manufacturing processes for fiberglass mat tissue?

- There are several different manufacturing processes for fiberglass mat tissue, each of which is designed to produce a specific type of mat with unique properties. One common manufacturing process is the wet-laid process. In this method, glass fibers are first chopped into small pieces and then dispersed in a water-based slurry. The slurry is then spread onto a moving screen or belt, allowing the water to drain away and leaving behind a mat of randomly oriented fibers. The mat is then dried and further processed to achieve the desired thickness and density. Another manufacturing process is the dry-laid process. In this method, glass fibers are first formed into a loose, fluffy mat using air or mechanical means. The loose fibers are then bonded together using a binder material, such as a resin or latex, which is sprayed onto the fibers. The binder cures, creating a cohesive mat with controlled thickness and density. A third manufacturing process is the stitch-bonded process. This method involves mechanically stitching individual glass fibers together using a series of needles. The needles pierce the fibers and interlock them, creating a bonded fabric. This process allows for the production of mats with high strength and dimensional stability. Finally, there is the spunbond process. This process involves extruding molten glass through fine spinnerets to form continuous filaments. The filaments are then collected onto a moving belt or screen, where they are bonded together using heat or a binder. This process produces mats with uniform fiber distribution and high strength. Overall, the choice of manufacturing process for fiberglass mat tissue depends on the desired properties of the final product, such as strength, thickness, density, and dimensional stability. Each process has its own advantages and disadvantages, and manufacturers will select the most suitable process based on their specific requirements.

- Q: What is the expected lifespan of fiberglass mat tissue in sports facility applications?

- The lifespan of fiberglass mat tissue in sports facility applications can differ based on various factors, including material quality, maintenance level, and usage conditions. However, fiberglass mat tissue generally has a lengthy lifespan and is recognized for its durability. When installed and maintained correctly, fiberglass mat tissue can endure for multiple decades. It is resistant to corrosion, rot, and degradation, making it suitable for use in sports facilities that face moisture, humidity, and other environmental factors. To ensure the longest lifespan for fiberglass mat tissue in sports facility applications, regular inspections, cleanings, and repairs may be necessary. Additionally, it is crucial to adhere to the manufacturer's recommendations for installation and maintenance to achieve optimal performance and longevity. It is important to note that despite its durability, fiberglass mat tissue may still experience gradual wear and tear, particularly in high-impact areas or facilities with heavy usage. In such cases, periodic replacements or repairs may be needed to maintain the material's integrity and functionality. All in all, fiberglass mat tissue is a dependable and long-lasting choice for sports facility applications. With proper care and maintenance, it can deliver exceptional performance and durability for numerous years.

- Q: Is fiberglass mat tissue suitable for insulation in pharmaceutical plants?

- Insulation in pharmaceutical plants cannot be accomplished with fiberglass mat tissue, as it does not meet the necessary criteria. The insulation materials used in pharmaceutical plants must fulfill specific requirements, including being non-porous, non-shedding, and resistant to moisture and chemicals. Unfortunately, fiberglass mat tissue is a porous substance that can shed fibers, posing a risk of contamination to the pharmaceutical production environment. Moreover, it may not offer sufficient protection against moisture and chemicals, both of which are prevalent in pharmaceutical plants. To ensure compliance with the required standards and regulations for insulation in these delicate environments, it is advisable to utilize insulation materials that are explicitly designed and certified for pharmaceutical applications.

Send your message to us

Fiberglass Mat Tissue E Glass Woven Roving Fabric for Hand Layup and Robot Process

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords