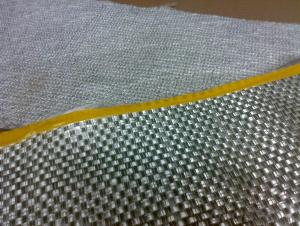

Fiberglass Mat Tissue - E Glass Fiber Woven Roving (200gsm-800gsm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

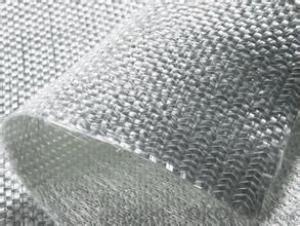

E-Glass Woven Rovings are bidirectional fabric made by interweaving direct rovings.

E-Glass Woven Rovings are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

2.Product Features

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Densely aligned fibers, resulting in high dimensional stability and making handling easy

Good moldability, fast and complete wet out in resins, resulting in high productivity

Good mechanical properties and high strength of parts

3.Product Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

Special specification can be produce according to customer requirements.

4.FAQ

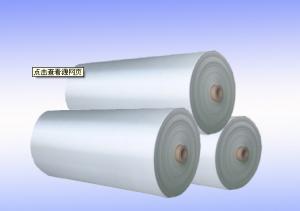

Packaging:

Each woven roving is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 220mm. The woven roving roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Are there any health risks associated with fiberglass mat tissue?

- Yes, there are some health risks associated with fiberglass mat tissue. Fiberglass contains tiny fibers that when inhaled can irritate the respiratory system and potentially cause lung damage. Prolonged or repeated exposure to fiberglass fibers can also lead to a condition called fiberglass dermatitis, which causes skin irritation and itching. Therefore, proper precautions such as wearing protective clothing and masks should be taken when handling fiberglass mat tissue to minimize the health risks.

- Q: What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its size and shape under various conditions. Fiberglass mat tissue is known for its excellent dimensional stability, making it highly resistant to shrinking, expanding, or warping. This stability is achieved through the manufacturing process, which involves bonding glass fibers together using a binder material. This binder not only ensures the integrity of the mat tissue but also helps it maintain its dimensional stability over time. Additionally, the inherent properties of fiberglass, such as its high strength and stiffness, contribute to its exceptional dimensional stability. These characteristics make fiberglass mat tissue a popular choice in various applications, including construction, automotive, and aerospace industries, where consistent dimensions are crucial for optimal performance and durability.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue can have a significant impact on its transportation process. The weight of the roll determines the ease of handling and the logistics required for transportation. Firstly, a heavier roll weight can make it more challenging to move and handle the fiberglass mat tissue. If the roll is too heavy, it may require specialized equipment or machinery for loading and unloading, such as forklifts or cranes. This can add complexity and cost to the transportation process. Moreover, the weight of the roll also affects the packaging and storage requirements during transportation. Heavier rolls may require sturdier packaging materials and additional precautions to ensure their stability and prevent any damage during transit. This can include using pallets, strapping, or other securing methods to prevent the roll from shifting or falling during transportation. The weight of the roll also impacts the overall cost of transportation. Heavier rolls can increase shipping costs, as carriers often charge based on weight. Additionally, the weight of the roll can affect the number of rolls that can be transported in a single shipment, which can impact the efficiency and cost-effectiveness of the transportation process. In summary, the roll weight of fiberglass mat tissue plays a crucial role in its transportation. It affects the ease of handling, packaging requirements, and overall cost of transportation. Therefore, it is essential to consider the roll weight when planning and organizing the logistics for transporting fiberglass mat tissue.

- Q: How is fiberglass mat tissue used in the production of chemical reactors?

- Fiberglass mat tissue is commonly used in the production of chemical reactors due to its exceptional properties. The mat tissue is made up of randomly oriented glass fibers, which are then bonded together with a binder material. This composition makes it an ideal material for the construction of chemical reactors. One of the primary uses of fiberglass mat tissue in chemical reactors is as a reinforcement material. The tissue is typically applied to the inner surfaces of the reactor to enhance its structural integrity. The combination of glass fibers and binder creates a strong and durable layer that can withstand the harsh conditions inside the reactor, such as high temperatures and corrosive chemicals. Additionally, fiberglass mat tissue also acts as a barrier against chemical attack. Chemical reactors often contain aggressive substances that can degrade traditional materials. However, the chemical resistance of fiberglass mat tissue makes it highly suitable for such environments. It effectively prevents the corrosive chemicals from penetrating the reactor walls, ensuring the longevity and reliability of the equipment. Furthermore, fiberglass mat tissue can also provide thermal insulation properties to chemical reactors. This is particularly important in processes where temperature control is crucial. The insulation properties of the tissue help maintain the desired temperature inside the reactor, preventing heat loss or gain, which could affect the efficiency and consistency of the chemical reactions. In summary, fiberglass mat tissue plays a vital role in the production of chemical reactors by reinforcing the structure, providing chemical resistance, and offering thermal insulation. Its unique properties make it an excellent choice for ensuring the durability, safety, and optimal performance of chemical reactors in various industrial applications.

- Q: Is fiberglass mat tissue suitable for construction applications?

- Yes, fiberglass mat tissue is suitable for construction applications. Fiberglass mat tissue is a versatile material that is commonly used in construction due to its strength, durability, and resistance to various environmental factors. It is often used in applications such as roofing, flooring, insulation, and wall panels. Fiberglass mat tissue is an excellent choice for construction projects because it provides reinforcement and stability to various materials. It adds strength to roofing materials, making them more resistant to impact, weathering, and fire. Similarly, it enhances the strength and durability of flooring systems, making them capable of withstanding heavy loads and foot traffic. Additionally, fiberglass mat tissue is an effective insulation material. It can be used to insulate walls, ceilings, and floors, helping to maintain a comfortable indoor temperature while reducing energy consumption. Its thermal and acoustic insulation properties make it an ideal choice for construction applications. Moreover, fiberglass mat tissue is resistant to moisture, chemicals, and corrosion, which makes it suitable for use in areas with high humidity or exposure to harsh chemicals. It does not rot or decay, making it a long-lasting option for construction projects. In conclusion, fiberglass mat tissue is well-suited for construction applications due to its strength, durability, insulation properties, and resistance to various environmental factors. Its versatility and reliability make it a popular choice in the construction industry.

- Q: Can fiberglass mat tissue be used for reinforcing swimming pools?

- Yes, fiberglass mat tissue can be used for reinforcing swimming pools. It is commonly used in the construction of pool shells to provide added strength and durability.

- Q: Is fiberglass mat tissue suitable for insulation in residential buildings?

- Yes, fiberglass mat tissue is suitable for insulation in residential buildings. It is a widely used and effective insulation material that offers excellent thermal performance, soundproofing capabilities, and fire resistance. Additionally, it is easy to install, durable, and does not degrade over time.

- Q: How does fiberglass mat tissue perform in terms of moisture vapor resistance?

- Fiberglass mat tissue is generally effective at resisting moisture vapor. It acts as a barrier, preventing the passage of water vapor and making it suitable for moisture control in applications like roofing and insulation. To enhance the moisture vapor resistance of fiberglass mat tissue, it can be combined with other materials like vapor barriers or moisture-resistant coatings. These additional layers provide extra protection against moisture infiltration, improving the overall performance of the fiberglass mat tissue. However, it should be noted that the moisture vapor resistance of fiberglass mat tissue can vary depending on factors such as thickness, density, and composition. Thicker and denser mats tend to offer higher resistance, while the presence of manufacturing additives or coatings can also affect the material's properties. In conclusion, fiberglass mat tissue is known for its moisture vapor resistance, but its performance may be influenced by various factors. It is recommended to consult product specifications or manufacturers' recommendations to determine the specific moisture vapor resistance of a particular fiberglass mat tissue product.

- Q: Can fiberglass mat tissue be used for making lightweight flooring?

- Yes, fiberglass mat tissue can be used for making lightweight flooring. Fiberglass mat tissue is a material that is commonly used in construction and manufacturing industries for its strength, durability, and lightweight properties. It is made by bonding fine fiberglass strands together with a binder, which results in a thin, flexible, and lightweight material. When used in flooring applications, fiberglass mat tissue can provide several advantages. Firstly, its lightweight nature makes it easier to handle and install, reducing the overall weight of the flooring system. This can be particularly beneficial in applications where weight is a concern, such as in aircraft or mobile homes. Additionally, fiberglass mat tissue is known for its excellent strength-to-weight ratio, making it a suitable material for creating lightweight yet strong flooring. It can provide reinforcement and improve the structural integrity of the flooring, making it more resistant to cracking, warping, or other forms of damage. Furthermore, fiberglass mat tissue is resistant to moisture, chemicals, and fire, making it a suitable choice for areas where these factors are present, such as bathrooms, kitchens, or industrial settings. It also offers good insulation properties, which can help in maintaining a comfortable indoor environment and reducing energy consumption. Overall, fiberglass mat tissue can be an excellent choice for making lightweight flooring due to its strength, durability, moisture resistance, and insulation properties. However, it is important to consider other factors such as the specific requirements of the flooring application, the load-bearing capacity, and the necessary certifications or standards before finalizing the use of fiberglass mat tissue in a flooring project.

- Q: Can fiberglass mat tissue be used for ballistic protection?

- Fiberglass mat tissue can be used for ballistic protection to some extent, but it may not offer the same level of protection as other materials specifically designed for this purpose. Fiberglass mat tissue is typically used in applications such as insulation, reinforcement, and fire resistance due to its high strength and heat resistance properties. However, when it comes to ballistic protection, there are more specialized materials available that are specifically engineered to withstand the impact of bullets or other projectiles. These materials often include aramid fibers (such as Kevlar) or ultra-high-molecular-weight polyethylene fibers (such as Dyneema) which are much more effective in providing superior ballistic protection. If ballistic protection is the primary concern, it is recommended to choose materials specifically designed for this purpose rather than relying solely on fiberglass mat tissue.

Send your message to us

Fiberglass Mat Tissue - E Glass Fiber Woven Roving (200gsm-800gsm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords