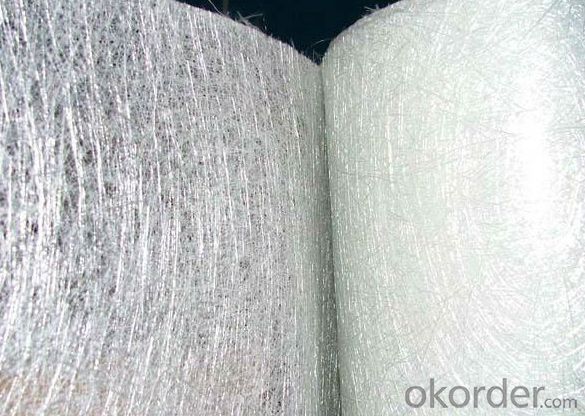

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2500mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 BOX kg

- Supply Capability:

- 1000MT kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Our chopped strand mat is with width 2500mm, packing in wooden box (pallet)with width 2550mm. In each 40HQ can be loaded 16-18 boxes(pallets), qualitu is around 2000kgs in each container.

2.Main Features

Our chopped strand mat factory specializes in manufacturing E-glass Chopped strand Mat (chopped strand mat manufacturer). The products range from chopped strand mat 300g/m2, chopped strand mat 450g/m2 to chopped strand mat 600g/m2 and 900g, the width from 102cm,104cm,125cm to 320cm.

Standard Specifications for Chopped strand mat

1. High quality

2. ISO9001, 2008 quality controled

3. 320cm width, 100g,300g,450gto 900g

3.Specifications

Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 |

3-4

|

300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

| 450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4

|

Package for Big Width Mat:

1, Each roll will be wound on 4 inches paper core, strong enough for the loading and transportation;

2, Each roll of mat will be wrapped by plastic film;

3, 9 Rolls wil be packed in one wooden frame box;

4, Both side closed by polywood;

5, Steel strip is used for fasten the wooden box.

4. FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

1000kgs;

4. Can you provide sample?

Yes, we can offer free sample for you.

5. Payment terms?

Accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

7. What is the Production Lead Time?

1 *40HQ each day, depend on the size of the mat.

- Q: Can fiberglass mat tissue be used as a reinforcement in concrete?

- Indeed, fiberglass mat tissue is a feasible option for reinforcing concrete. Composed of fine, lightweight material woven from fiberglass strands, this material is widely used in construction and industrial settings due to its exceptional strength and durability. By incorporating fiberglass mat tissue as reinforcement in concrete, the tensile strength and resistance to cracks can be significantly improved. Typically, it is applied in the form of a mesh or fabric, which is embedded within the concrete during its pouring phase. The presence of fiberglass strands in the mat tissue adds extra strength and reinforcement to the concrete, thereby reducing the likelihood of cracks and enhancing the overall structural integrity. This feature proves especially advantageous in areas where the concrete is subjected to heavy loads, such as bridges, concrete slabs, or precast concrete elements. Furthermore, fiberglass mat tissue possesses corrosion-resistant properties, which renders it a suitable choice in scenarios where the concrete comes into contact with moisture or chemicals. Unlike traditional steel reinforcement, it does not rust or deteriorate over time, thereby extending the lifespan of the concrete structure. To summarize, fiberglass mat tissue serves as a practical and efficient solution for reinforcing concrete. It offers improved strength, crack resistance, and corrosion resistance, making it a favored choice in various construction projects.

- Q: Can fiberglass mat tissue be used for bridge deck rehabilitation?

- Yes, fiberglass mat tissue can be used for bridge deck rehabilitation. Fiberglass mat tissue is a versatile material that is known for its high strength and durability. It is commonly used in construction projects, including bridge deck rehabilitation, due to its ability to reinforce and strengthen existing structures. Bridge deck rehabilitation involves repairing and restoring the deck of a bridge that has deteriorated over time. This process typically involves removing the existing damaged concrete, applying a new layer of concrete, and reinforcing it with materials such as fiberglass mat tissue. Fiberglass mat tissue is often used as a reinforcement material in bridge deck rehabilitation due to its excellent mechanical properties. It has high tensile strength, which helps to increase the load-bearing capacity of the bridge deck. Additionally, it is resistant to corrosion, which is particularly important in bridge decks that are exposed to harsh weather conditions and chemicals. Furthermore, fiberglass mat tissue is easy to install and can be applied to bridge decks of various shapes and sizes. It can be embedded into the new concrete layer during construction or applied as an overlay on the existing deck. This flexibility makes it an ideal choice for bridge deck rehabilitation projects. In summary, fiberglass mat tissue can indeed be used for bridge deck rehabilitation. Its high strength, durability, and resistance to corrosion make it a suitable reinforcement material for repairing and strengthening bridge decks. Its ease of installation and versatility further contribute to its suitability for this application.

- Q: How does fiberglass mat tissue perform in terms of thermal conductivity?

- Fiberglass mat tissue performs well in terms of thermal conductivity. Due to its composition of fine glass fibers, it has a low thermal conductivity value, meaning it is a good insulator against heat transfer. The interlocking fibers create a barrier that slows down the movement of heat, making it an effective material for thermal insulation applications. Additionally, the mat tissue is often combined with other materials, such as binders or coatings, to enhance its thermal resistance properties. Overall, fiberglass mat tissue is a reliable choice when it comes to minimizing thermal conductivity and providing insulation in various industries and applications.

- Q: What are the different quality standards for fiberglass mat tissue?

- Various quality standards are utilized to evaluate the quality of fiberglass mat tissue, ensuring its suitability for intended applications and meeting performance requirements. The ASTM D2178 standard is widely used to assess the quality of fiberglass mat tissue. This standard outlines the specifications for base materials used in the production of asphalt and coal tar roofing products. It covers physical properties such as weight, thickness, tensile strength, tear resistance, and permeability. Another recognized standard is ISO 3376, which provides guidelines for determining the tensile properties of nonmetallic materials, including fiberglass mat tissue. It defines test methods for parameters like tensile strength, elongation at break, and modulus of elasticity. In Europe, the EN 1871 standard is commonly used for assessing the quality of fiberglass mat tissue. This standard specifies the requirements for reinforced bitumen sheets used in roofing applications. It covers physical properties, dimensional stability, resistance to heat, and resistance to aging. Furthermore, there are industry-specific quality standards that may apply to fiberglass mat tissue used in particular applications. For instance, the ASTM C1666 standard specifically addresses fiberglass reinforced cementitious panels and sets requirements for the materials used in their production. Overall, these various quality standards for fiberglass mat tissue ensure that it meets specific performance criteria and can be effectively utilized in applications such as roofing, construction, and insulation. They establish a framework for manufacturers, suppliers, and customers to assess and compare the quality of different products in the market.

- Q: Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable.

- Q: Is fiberglass mat tissue suitable for electrical insulation applications?

- Fiberglass mat tissue proves to be a fitting choice for electrical insulation purposes. Comprised of glass fibers intricately fused with resin, it yields a robust and long-lasting substance. Its remarkable electrical insulation traits, including a high dielectric strength and low electrical conductivity, render it perfect for situations necessitating electrical insulation, like those found in transformers, motors, and electrical switchgear. Furthermore, the added resistance to moisture, chemicals, and heat amplifies its aptness for electrical insulation applications.

- Q: Can fiberglass mat tissue be used for making lightweight ceilings?

- Yes, fiberglass mat tissue can be used for making lightweight ceilings. Fiberglass mat tissue is a thin and lightweight material made from fiberglass strands that are bonded together with a binder. It is commonly used in construction and building applications due to its excellent strength-to-weight ratio. When used for making lightweight ceilings, fiberglass mat tissue can provide several advantages. Firstly, it is lightweight, which makes it easier to handle and install. This can save time and effort during construction or renovation projects. Additionally, fiberglass mat tissue is also known for its high tensile strength and durability, making it a suitable choice for ceilings that need to withstand various loads and stresses. Furthermore, fiberglass mat tissue has good thermal insulation properties, which can help in maintaining a comfortable indoor environment. It can also offer sound insulation benefits, reducing noise transmission between different spaces or floors. Moreover, fiberglass mat tissue is resistant to moisture, mold, and mildew, which makes it suitable for areas with high humidity or moisture concerns such as bathrooms or kitchens. It is also non-combustible, providing an added level of fire resistance to the ceiling structure. In conclusion, fiberglass mat tissue can indeed be used for making lightweight ceilings. Its lightweight nature, strength, durability, thermal and sound insulation properties, as well as resistance to moisture and fire, make it a suitable choice for various ceiling applications.

- Q: Can fiberglass mat tissue be used for making lightweight doors?

- Yes, fiberglass mat tissue can be used for making lightweight doors. Fiberglass mat tissue is a lightweight material that is commonly used in various industries for its strength and durability. It is made of thin strands of fiberglass that are bonded together with a binder, resulting in a strong and flexible material. When used in the construction of doors, fiberglass mat tissue offers several advantages. Firstly, it is lightweight, making it ideal for creating doors that are easy to handle and install. This can be particularly beneficial in residential or commercial settings where doors are frequently opened and closed. Additionally, fiberglass mat tissue possesses excellent thermal and acoustic insulation properties. This means that doors made with this material can effectively block out noise and regulate temperature, creating a more comfortable and energy-efficient environment. Furthermore, fiberglass mat tissue is resistant to moisture, rot, and insects, making it a durable and long-lasting option for door construction. It can withstand harsh weather conditions, making it suitable for both interior and exterior doors. Overall, fiberglass mat tissue is a versatile material that can be used to create lightweight doors that offer strength, durability, insulation, and resistance to various environmental factors.

- Q: How does the width of fiberglass mat tissue affect its conformability?

- The width of fiberglass mat tissue does not directly affect its conformability. Conformability is primarily determined by the flexibility and pliability of the material itself, rather than its width.

- Q: What are the potential health and safety concerns associated with working with fiberglass mat tissue?

- Working with fiberglass mat tissue can pose several potential health and safety concerns. Firstly, fiberglass contains tiny glass fibers that can become airborne when the material is cut, sanded, or disturbed. Inhalation of these fibers can lead to respiratory problems such as coughing, wheezing, and difficulty breathing. Prolonged exposure to fiberglass dust may also cause lung diseases like fibrosis or even lung cancer. Additionally, direct contact with fiberglass mat tissue can irritate the skin, leading to itching, redness, and rashes. The sharp edges of the glass fibers can cause tiny cuts or punctures, which may become infected if not properly treated. Moreover, fiberglass is a lightweight material that can easily become airborne and settle on surfaces, increasing the risk of ingestion or contamination of food and drinks. Ingesting fiberglass particles can irritate the digestive system, causing nausea, vomiting, and abdominal pain. To ensure the health and safety of workers, proper precautions should be taken when working with fiberglass mat tissue. This includes wearing personal protective equipment such as gloves, safety glasses, and respiratory masks to minimize exposure to airborne fibers. Adequate ventilation and dust control measures should also be in place to prevent the accumulation of fiberglass dust in the work area. Regular cleaning and maintenance should be performed to keep the work environment free from fiberglass particles. Workers should be educated on the proper handling and disposal of fiberglass materials to minimize the risk of contamination. Overall, while fiberglass mat tissue is a widely used material, it is important to be aware of the potential health and safety concerns associated with its handling and take necessary precautions to minimize the risk of exposure.

Send your message to us

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2500mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 BOX kg

- Supply Capability:

- 1000MT kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords