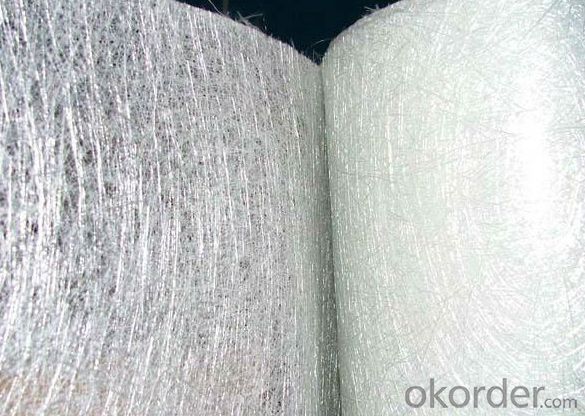

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Chopped strand mat with width 2200mm

Our chopped strand mat is with width 2200mm, packing in wooden box (pallet)with width 2250mm. In each 40HQ can be loaded 16-18 boxes(pallets), qualitu is around 2000kgs in each container.

2.Main Features

Standard Specifications for Chopped strand mat

1. High quality

2. ISO9001, 2008 quality controled

3. 320cm width, 100g,300g,450gto 900g

Our chopped strand mat factory specializes in manufacturing E-glass Chopped strand Mat (chopped strand mat manufacturer). The products range from chopped strand mat 300g/m2, chopped strand mat 450g/m2 to chopped strand mat 600g/m2 and 900g, the width from 102cm,104cm,125cm to 320cm.

3.Specifications

Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

| 450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: How does fiberglass mat tissue perform in terms of air permeability?

- Fiberglass mat tissue typically has low air permeability. The tight weave and construction of the fiberglass strands used in the mat tissue make it less porous, allowing very little air to pass through it. This characteristic makes fiberglass mat tissue a suitable material for applications where air permeability needs to be minimized, such as in insulation or filtration systems. By restricting the passage of air, fiberglass mat tissue helps to enhance thermal insulation properties and improve filtration efficiency.

- Q: How is fiberglass mat tissue used in the production of windshields?

- Fiberglass mat tissue is a crucial component in the production of windshields due to its unique properties and functions. When manufacturing windshields, the fiberglass mat tissue is used as a reinforcement material to enhance the strength and durability of the glass. During the production process, a layer of fiberglass mat tissue is inserted between two layers of glass to create a laminated structure. This layer acts as a barrier, preventing the glass from shattering into small dangerous pieces upon impact. It helps to hold the glass together, providing safety to the vehicle occupants. The fiberglass mat tissue serves as a reinforcing material, improving the mechanical properties of the windshield. It enhances the impact resistance, making the windshield less prone to cracks or chips from stones, debris, or other objects that may hit it while driving. This reinforcement also adds structural integrity to the windshield, allowing it to withstand extreme weather conditions and vibrations without compromising its functionality. Furthermore, the fiberglass mat tissue helps to reduce noise transmission and vibrations. It has sound-damping properties, which contribute to a quieter and more comfortable driving experience by reducing external noise from entering the vehicle cabin. Additionally, the use of fiberglass mat tissue allows for the production of curved windshields. The flexibility of the material enables it to conform to different shapes and contours, allowing manufacturers to create windshields with customized designs and improved aerodynamics. In summary, fiberglass mat tissue plays a vital role in the production of windshields. Its reinforcement properties enhance the strength and impact resistance of the glass, providing safety to the vehicle occupants. It also contributes to a quieter driving experience and enables the production of curved windshields with improved aerodynamics.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: Does fiberglass mat tissue provide any mold resistance?

- While fiberglass mat tissue alone does not possess natural mold resistance, its combination with other mold-resistant materials and proper construction techniques can aid in preventing mold. The fiberglass mat tissue itself may not resist mold growth, but it can be employed as a strengthening layer in mold-resistant building materials like mold-resistant drywall or sheathing. These materials are specifically engineered to hinder the growth of mold and mildew by incorporating additives or coatings. It is also crucial to guarantee the correct installation and upkeep of these materials to minimize moisture accumulation and establish an unfavorable setting for mold to thrive.

- Q: How does fiberglass mat tissue compare to mineral wool insulation?

- Construction and other industries commonly use fiberglass mat tissue and mineral wool insulation as insulation materials. While both serve the purpose of providing thermal insulation, there are differences between them. Fiberglass mat tissue consists of bonded fine glass fibers that form a lightweight and flexible mat. This makes it easy to handle and install. It is also resistant to moisture, mold, and pests, making it a durable option. Its high R-value, which measures heat flow resistance, makes it an effective insulator. On the other hand, mineral wool insulation is made from natural minerals like basalt, diabase, or slag. It is usually denser and heavier than fiberglass mat tissue. Mineral wool insulation has excellent fire resistance properties and can withstand high temperatures. It also provides sound insulation, reducing noise transmission. However, it can absorb moisture, which may decrease its effectiveness over time. Both materials offer similar levels of insulation in terms of thermal performance. However, fiberglass mat tissue is slightly more efficient due to its higher R-value. Additionally, it is generally more affordable compared to mineral wool insulation. In conclusion, fiberglass mat tissue and mineral wool insulation are both effective insulation materials. The choice between them depends on specific project requirements, such as fire resistance, sound insulation, cost, and moisture resistance. It is crucial to consider these factors and seek professional advice to determine the most suitable insulation material for a particular application.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Fiberglass mat tissue can be suitable for soundproofing purposes, but its effectiveness may vary depending on the specific requirements and desired level of soundproofing. Fiberglass mat tissue is a lightweight and flexible material that can effectively absorb and dampen sound waves. It has good acoustic properties and can help reduce noise transmission, making it a viable option for soundproofing applications. However, it is important to note that fiberglass mat tissue alone may not provide sufficient soundproofing, especially in high-noise environments. For optimal results, it is recommended to combine it with other soundproofing materials such as acoustic foam panels or mass-loaded vinyl to enhance its soundproofing capabilities. Additionally, the thickness and density of the fiberglass mat tissue can also affect its sound absorption properties. Thicker and denser mats are generally more effective at attenuating sound waves, but they may also be less flexible and harder to install. In conclusion, while fiberglass mat tissue can contribute to soundproofing efforts, its suitability depends on the specific requirements, desired level of soundproofing, and the use of additional materials. Consulting with a soundproofing expert or conducting thorough research on the specific application is recommended to determine the most appropriate solution for effective soundproofing.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The adhesion of resin to fiberglass mat tissue can be significantly influenced by its surface finish. The surface finish pertains to the texture or smoothness of the fiberglass mat tissue. In general, a rough surface finish tends to promote better adhesion to resin. This is because a rough surface provides a larger area for the resin to adhere to, resulting in a stronger bond. Rough surface finishes can be achieved through different manufacturing techniques, such as using coarser fibers or incorporating texturizing agents during production. On the contrary, a smoother surface finish may lead to weaker adhesion. A smooth surface does not offer as much area for the resin to bond with, resulting in a weaker and less durable bond. Smoother surface finishes can be attained by using finer fibers or through additional processing steps to smoothen the surface. When selecting the surface finish of fiberglass mat tissue, it is crucial to consider the specific application and requirements. For applications that necessitate high strength and durability, a rougher surface finish may be preferable to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a vital role in determining the adhesion to resin. It is essential to choose the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: What is the expected lifespan of fiberglass mat tissue in cryogenic applications?

- The expected lifespan of fiberglass mat tissue in cryogenic applications can vary depending on various factors such as the specific temperature, exposure time, and the quality of the material. However, in general, fiberglass mat tissue is known for its durability and resistance to extreme temperatures, making it suitable for long-term use in cryogenic applications. With proper installation and maintenance, it can potentially last for several years or even decades in such environments.

- Q: What are the different types of fiberglass mat tissue available in the market?

- In the market, you can find various types of fiberglass mat tissue, each with its own distinct characteristics and applications. 1. Chopped Strand Mat (CSM): This is a commonly used fiberglass mat tissue. It consists of randomly oriented chopped strands of glass fibers held together by a binder. CSM is widely utilized in industries like construction, automotive, and marine due to its excellent strength and cost-effectiveness. 2. Continuous Filament Mat (CFM): Unlike CSM, CFM is made up of continuous strands of glass fibers. This type of fiberglass mat tissue offers enhanced strength and stiffness, making it suitable for applications that require higher performance and durability. 3. Woven Roving: Woven roving is created by weaving parallel rovings together. It provides a higher strength-to-weight ratio compared to CSM and CFM, making it ideal for applications that require additional reinforcement. 4. Surface Veil: Surface veils are lightweight fiberglass mat tissues primarily used for surface protection and cosmetic purposes. They are typically applied as a thin layer on the surface of other fiberglass materials to improve smoothness, appearance, and resistance to cracking or chipping. 5. Stitched Mat: Stitched mat is a type of fiberglass mat tissue where the fibers are stitched together using thread or yarn. This stitching enhances the mat's stability and structural integrity, making it suitable for applications that require enhanced dimensional stability and strength. 6. Composite Mat: Composite mat is a combination of different materials, including fiberglass, polyester, and other synthetic fibers. It offers a unique combination of properties such as strength, flexibility, and resistance to chemicals, making it suitable for a wide range of applications. In conclusion, the market provides a diverse range of fiberglass mat tissues to cater to specific needs and requirements in various industries.

- Q: What are the different methods of bonding fiberglass mat tissue to other materials?

- There are various ways to bond fiberglass mat tissue to other materials, each with its own advantages and considerations. Some commonly used methods are as follows: 1. Mechanical Bonding: This technique involves physically interlocking the fiberglass mat tissue with the other material. It can be achieved through stitching, stapling, or using mechanical fasteners like screws or nails. While mechanical bonding provides a strong and durable connection, it may require additional hardware and can be time-consuming. 2. Adhesive Bonding: Adhesive bonding is a popular method that utilizes adhesives or glue to join the fiberglass mat tissue with the other material. This method offers flexibility, as there are different types of adhesives available for various applications. It is important to select an adhesive that is compatible with both the fiberglass mat tissue and the other material. Proper surface preparation and application techniques are crucial for achieving a strong bond. 3. Resin Infusion: Resin infusion involves infusing a liquid resin into the fiberglass mat tissue and other materials, resulting in a strong bond when cured. This method is commonly used in manufacturing composite products, as it allows for a seamless and uniform bond. Vacuum bagging or resin infusion techniques are typically employed to ensure proper resin distribution and consolidation. 4. Thermal Bonding: Thermal bonding employs heat to bond the fiberglass mat tissue to another material. This technique is particularly suitable for thermoplastic materials, as they can be softened and fused together with heat. Heat welding or ultrasonic welding are commonly used techniques for thermal bonding. Care must be taken to prevent damage or degradation of the fiberglass mat tissue during the bonding process. 5. Fusion Bonding: Fusion bonding is a method where the fiberglass mat tissue and the other material are heated to a molten state and then brought into contact to form a bond. This technique is commonly used in the manufacturing of thermosetting plastics or joining thermoplastic materials. Fusion bonding can provide a strong and seamless bond, but it requires precise control of temperature and pressure to ensure proper bonding without causing damage. To summarize, the various methods of bonding fiberglass mat tissue to other materials include mechanical bonding, adhesive bonding, resin infusion, thermal bonding, and fusion bonding. The choice of bonding method depends on factors such as the materials being bonded, the desired strength and durability, and the specific application requirements.

Send your message to us

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords