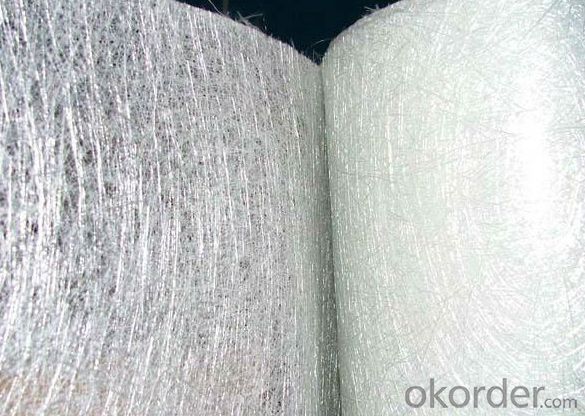

Fiberglass Mat Tissue e-glass Chopped Strand Mat 3200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Chopped strand mat with width 3200mm

2.Main Features

Our chopped strand mat is with width 3200mm, packing in wooden box (pallet)with width 3250mm. In each 40HQ can be loaded 16-18 boxes(pallets), qualitu is around 2000kgs in each container.

Standard Specifications for Chopped strand mat

1. High quality

2. ISO9001, 2008 quality controled

3. 320cm width, 100g,300g,450gto 900g

Our chopped strand mat factory specializes in manufacturing E-glass Chopped strand Mat (chopped strand mat manufacturer). The products range from chopped strand mat 300g/m2, chopped strand mat 450g/m2 to chopped strand mat 600g/m2 and 900g, the width from 102cm,104cm,125cm to 320cm.

3.Specifications

Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

| 450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: What is the UV resistance of fiberglass mat tissue?

- The UV resistance of fiberglass mat tissue can vary depending on the specific formulation and manufacturing process used. Generally, fiberglass mat tissue is known for its excellent resistance to ultraviolet (UV) radiation. The fiberglass strands used in the mat are typically coated with a resin or binder that provides added protection against UV degradation. This coating helps to prevent the fibers from breaking down or becoming brittle when exposed to sunlight. Additionally, the structure of the fiberglass mat tissue itself provides a degree of natural UV resistance due to its dense and tightly woven construction. However, it is important to note that prolonged exposure to intense UV radiation can still cause some degree of degradation over time. Therefore, it is recommended to consult the specific product specifications or manufacturer's guidelines for accurate information on the UV resistance of a particular fiberglass mat tissue.

- Q: How does the roll length of fiberglass mat tissue affect its handling?

- The roll length of fiberglass mat tissue can have an impact on its handling in several ways. Firstly, a longer roll length means that the roll will be heavier and larger in size. This can make it more challenging to handle and maneuver, especially if the roll needs to be transported or lifted to different areas. It may require additional manpower or equipment to safely handle and move the roll. Secondly, the length of the roll can also affect how easily the fiberglass mat tissue can be unrolled and cut to size. Longer rolls may be more prone to tangling or becoming tangled, which can make it more difficult to unroll the tissue smoothly and evenly. This can result in wasted material or uneven application. Additionally, the length of the roll can also impact the storage and space requirements. Longer rolls may take up more space and require larger storage areas. This can be a consideration for manufacturers or distributors who need to store large quantities of fiberglass mat tissue. In summary, the roll length of fiberglass mat tissue can affect its handling by making it heavier and more difficult to maneuver, potentially leading to tangling or uneven unrolling, and requiring larger storage space.

- Q: Can fiberglass mat tissue be used for insulation in underground pipelines?

- Indeed, insulation in underground pipelines can be achieved using fiberglass mat tissue. Renowned for its outstanding thermal insulation characteristics, fiberglass mat tissue is widely employed across diverse industrial sectors, including underground pipeline installations. By impeding heat transfer between the pipeline and its surroundings, it effectively sustains the desired temperature within the pipeline, thereby providing insulation. Furthermore, fiberglass mat tissue exhibits resistance against moisture, chemicals, and corrosion, rendering it an optimal selection for underground scenarios where pipelines face harsh conditions. Consequently, fiberglass mat tissue emerges as a dependable and efficacious insulation material for underground pipelines.

- Q: Can fiberglass mat tissue be used for insulation in cryogenic applications?

- Yes, fiberglass mat tissue can be used for insulation in cryogenic applications. Fiberglass is a versatile material known for its excellent thermal insulation properties. It has a low thermal conductivity, which means it is highly effective at reducing heat transfer. This makes it suitable for cryogenic applications where maintaining extremely low temperatures is crucial. Additionally, fiberglass is non-combustible and does not absorb moisture, making it ideal for cryogenic environments. It can be used as a layer of insulation in cryogenic storage tanks, pipes, and other equipment to prevent heat transfer and maintain the desired low temperatures.

- Q: Is fiberglass mat tissue resistant to moisture?

- Yes, fiberglass mat tissue is resistant to moisture.

- Q: How is fiberglass mat tissue used in the production of printed circuit boards?

- Fiberglass mat tissue is commonly used in the production of printed circuit boards (PCBs) as a reinforcement material. PCBs are typically made of layers of copper, insulating materials, and fiberglass. The fiberglass mat tissue serves as a structural support and helps provide mechanical strength to the PCB. During the manufacturing process, the fiberglass mat tissue is impregnated with a resin, usually epoxy, to form a laminate material. This laminate is then layered with copper foils, which act as conductive pathways for the electrical signals on the PCB. The fiberglass mat tissue plays a crucial role in the PCB's performance and reliability. It provides a solid foundation for the copper layers, preventing them from delaminating or warping due to mechanical stress or temperature changes. It also helps to maintain the dimensional stability of the PCB, ensuring that it remains flat and rigid. Furthermore, the fiberglass mat tissue enhances the PCB's resistance to heat and moisture. The epoxy resin used in the laminate offers excellent insulation properties, protecting the copper conductors from short circuits or electrical leakage. Additionally, the fiberglass mat tissue acts as a barrier against moisture absorption, preventing the PCB from becoming damaged or malfunctioning. In summary, fiberglass mat tissue is an essential component in the production of printed circuit boards. It provides structural support, enhances mechanical strength, ensures dimensional stability, and improves resistance to heat and moisture. Ultimately, the use of fiberglass mat tissue contributes to the overall reliability and performance of PCBs in various electronic devices.

- Q: Can fiberglass mat tissue be used for insulating radiant floors?

- Indeed, insulating radiant floors is possible with the use of fiberglass mat tissue. This material, known for its exceptional thermal properties and moisture resistance, is widely favored for insulation purposes. Specifically engineered to enhance the strength and endurance of the insulation layer, fiberglass mat tissue effectively inhibits heat loss and enhances energy efficiency in radiant floor systems. By creating a shield between the heated floor and the colder ground or subfloor, it effectively prevents heat escape. Moreover, installing fiberglass mat tissue is hassle-free, as it can be easily tailored to fit any desired shape or size. This remarkable adaptability makes it a versatile option for insulating radiant floors.

- Q: Can fiberglass mat tissue be used in wet environments?

- Yes, fiberglass mat tissue can be used in wet environments. It is resistant to water and can withstand exposure to moisture without losing its structural integrity.

- Q: Can fiberglass mat tissue be used in automotive applications?

- Yes, fiberglass mat tissue can be used in automotive applications. It is commonly used as a reinforcement material in automotive parts such as hoods, fenders, and interior panels.

- Q: How does the width of fiberglass mat tissue affect its conformability?

- The conformability of fiberglass mat tissue can be significantly influenced by its width. In general, a wider width allows for greater flexibility and adaptability to various surfaces and shapes. This is due to the fact that a broader mat tissue can cover larger areas, resulting in smoother transitions and improved conformability to irregular surfaces. Conversely, a narrower width of fiberglass mat tissue may be more rigid and less capable of conforming to intricate shapes or contours. It may struggle to adhere properly to uneven surfaces, leading to potential gaps or imperfections. Moreover, a narrower width might restrict the flexibility and maneuverability of the mat tissue during installation or application. Thus, when determining the conformability of fiberglass mat tissue, it is crucial to consider its width. Generally, a wider width provides superior conformability and the ability to cover larger areas, while a narrower width may have limitations in adapting to complex surfaces.

Send your message to us

Fiberglass Mat Tissue e-glass Chopped Strand Mat 3200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords