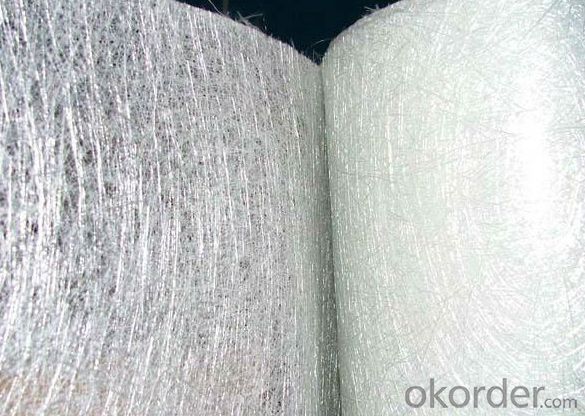

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2300mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Chopped strand mat with width 2300mm

2.Main Features

With Excellent compatibility with resin,heating resistance,Faster and well wet-out

Chopped strand mats are made of chopped strands of 50mm in length,which are randomly dispersed and bonded together by the polyester binder in powder or emulsion.

Chopped strand mats are mainly used in FRP fields,such as hand lay-up,filament winding and molding process. The typical products are panels,tanks,boats,automotive parts,cooling towers,pipes and so on.

3.Specifications

Glass type: E-glass

Bond type: Powder or Emulsion.

Normal types : 180g/m2. 225g/m2. 300g/m2 450g/m2. 600m2.

Roll Width: 2300mm.

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for soundproofing?

- Yes, fiberglass mat tissue can be used for soundproofing. Fiberglass is known for its excellent sound absorption properties. When used as a mat or tissue, it can effectively reduce noise transmission by absorbing and dampening sound waves. The porous nature of fiberglass allows it to trap and dissipate sound energy, making it an ideal material for soundproofing applications. Additionally, fiberglass is lightweight, flexible, and easy to install, making it a practical choice for soundproofing projects.

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass roofs?

- Indeed, fiberglass mat tissue is a suitable option for reinforcing fiberglass roofs. Comprised of delicate fibers that are joined together using a binder, fiberglass mat tissue is a thin and lightweight material. It is widely utilized as a reinforcement layer in fiberglass composites, providing them with robustness and endurance. Concerning fiberglass roofs, fiberglass mat tissue can be applied as an extra layer to enhance the roof's structural integrity. This additional layer aids in evenly distributing the load across the surface, thereby augmenting the roof's resistance against cracks, leaks, and other types of damage. Typically, fiberglass mat tissue is used alongside other fiberglass products, including resin and fiberglass cloth, to generate a sturdy composite material. The mat tissue is placed atop the fiberglass cloth prior to the application of resin. Subsequently, the resin saturates the mat tissue, establishing a bond between the layers. This combination results in a reinforced fiberglass roof that possesses heightened strength and durability. Moreover, fiberglass mat tissue can confer thermal insulation properties to the roof, contributing to temperature regulation and reduced energy consumption. It exhibits resistance against heat transfer, thereby preventing excessive heat accumulation within the building during hot weather. All in all, fiberglass mat tissue is an exceptional choice for reinforcing fiberglass roofs. By adding strength, durability, and thermal insulation properties to the roof, it becomes a reliable option for both residential and commercial buildings.

- Q: Is fiberglass mat tissue easy to install?

- Yes, fiberglass mat tissue is relatively easy to install. It is a lightweight and flexible material that can be easily cut and shaped to fit any surface. It can be applied using various methods such as spraying, rolling, or brushing on adhesive. The tissue is also self-adhesive, which makes it even easier to install as it can easily stick to the desired surface. Additionally, fiberglass mat tissues are typically designed to be water-resistant and provide excellent insulation properties, making them a popular choice for a wide range of applications. Overall, with proper preparation and following the manufacturer's instructions, installing fiberglass mat tissue can be a straightforward and hassle-free process.

- Q: Can fiberglass mat tissue be used for making fiberglass molds?

- Yes, fiberglass mat tissue can be used for making fiberglass molds. It is often used as a reinforcement layer to provide strength and stability to the mold, allowing it to withstand the pressures and forces exerted during the molding process.

- Q: Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable. Fiberglass is a synthetic material made from fine fibers of glass, which are woven together to create a strong and durable material. These fibers do not break down naturally over time, making fiberglass mat tissue non-biodegradable.

- Q: Is fiberglass mat tissue suitable for insulation in laboratories?

- Yes, fiberglass mat tissue is suitable for insulation in laboratories. It offers excellent thermal insulation properties, is resistant to high temperatures, and provides effective sound insulation. Additionally, it is non-combustible and chemically inert, making it ideal for laboratory environments where safety and performance are crucial.

- Q: What is the expected lifespan of fiberglass mat tissue in chemical storage applications?

- The expected lifespan of fiberglass mat tissue in chemical storage applications can vary depending on factors such as the specific chemicals being stored, the conditions of storage (temperature, humidity, etc.), and the quality of the fiberglass material. However, fiberglass mat tissue is generally known for its durability and resistance to corrosion, making it suitable for long-term use in chemical storage applications. With proper maintenance and care, it can typically last for many years.

- Q: Can fiberglass mat tissue be used for making insulation panels?

- Indeed, insulation panels can be manufactured using fiberglass mat tissue. This lightweight and flexible material possesses remarkable thermal insulation characteristics. Typically, it is utilized as a reinforcing layer during the production process of insulation panels. By doing so, the mat tissue not only fortifies the panels, but also ensures efficient insulation against heat transfer. Moreover, fiberglass mat tissue exhibits resistance against moisture, mold, and mildew, rendering it highly suitable for insulation purposes.

- Q: How does the width of fiberglass mat tissue affect its installation?

- The width of fiberglass mat tissue can have an impact on its installation process. When considering the width of fiberglass mat tissue, it is important to take into account the specific application or project requirements. A wider fiberglass mat tissue can offer several advantages during installation. Firstly, it allows for greater coverage area, reducing the number of overlaps needed and potentially saving installation time. This can be particularly beneficial in large-scale projects where efficiency is crucial. Additionally, a wider width can provide better overall coverage and reduce the risk of potential gaps or weak spots in the installation. This can result in a more consistent and reliable finished product, ensuring enhanced performance and durability. However, it is worth noting that a wider fiberglass mat tissue may also present certain challenges during installation. It can be more difficult to handle and maneuver, especially when working in tight or confined spaces. This can require additional care and attention to ensure proper alignment and smooth application. Furthermore, the width of fiberglass mat tissue can impact the amount of resin or adhesive required for installation. A wider width may necessitate a larger quantity of resin or adhesive, potentially increasing the overall project cost. Ultimately, the choice of fiberglass mat tissue width should be based on the specific needs and constraints of the project. Factors such as the size of the installation area, the level of coverage required, and the available resources should all be taken into consideration to determine the most suitable width for the application.

- Q: What is the abrasion resistance of fiberglass mat tissue?

- The abrasion resistance of fiberglass mat tissue is high, making it suitable for applications that require durability and resistance to wear and tear.

Send your message to us

Fiberglass Mat Tissue e-glass Chopped Strand Mat 2300mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords