Dye Sublimation Prepainted Mill Finished Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

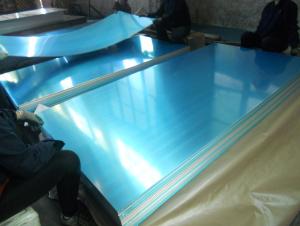

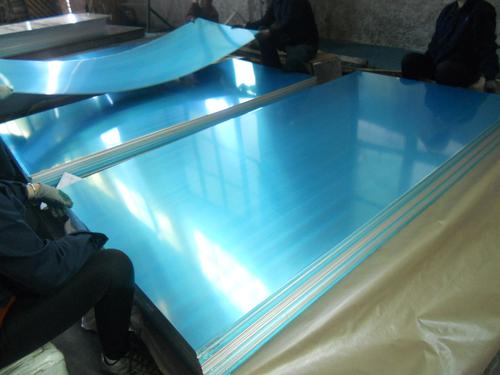

1.Structure of Mill Finished Aluminium Sheet for Prepainting Color

Mill Finished Aluminium Sheet for Prepainting Color is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Sheet for Prepainting Color

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1050 | H14 | 0.2-3MM | 1000MM-1500MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the density of aluminum plate?

- Pure aluminum plate density: 2.71 alloy aluminum plate density: 2.8 antirust aluminum plate density: 2.73

- Q: How much is the price of the 6061 aluminum plate?

- Therefore, according to your specifications, quantity and use in what place (that is, quality requirements) in order to quote.Or give you a reference priceMore than 8MM thickness of the domestic low-end (that is, the surface black, flatness is not how kind of) price of 20 yuan /KG or soMade in China at the end of the price of 25-30 yuan /KG, domestic high-end 30 yuan /KG or more.Imports are usually 40-80/KGThe thickness below 8MM is quoted according to the actual thickness

- Q: What is the thickness of the aluminum sheets?

- Depending on the specific product or application, the thickness of the aluminum sheets may vary. Aluminum sheets come in a diverse range of thicknesses, typically varying from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm) or possibly even thicker. The suitable thickness will be determined by the specific requirements and intended usage of the aluminum sheet.

- Q: This question asks about the various types of paint that can be used specifically for aluminum sheets, indicating an interest in paint compatibility and options for this particular material.

- <p>There are several types of paints suitable for aluminum sheets, each offering unique properties. These include: 1. Acrylic Paints - Water-based, easy to apply, and offer good adhesion. 2. Epoxy Paints - Known for their durability and chemical resistance, they provide a strong bond to the metal. 3. Enamel Paints - Provide a hard, glossy finish and are resistant to chipping and scratching. 4. Polyester Paints - Offer excellent durability and UV resistance, making them suitable for exterior applications. 5. Powder Coatings - Applied electrostatically, they provide a tough, scratch-resistant finish. 6. Specialty Paints - Such as heat-resistant or anti-corrosive paints, designed for specific industrial applications. The choice of paint depends on the application, desired finish, and environmental conditions.</p>

- Q: Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Indeed, chemical storage tanks can be manufactured using aluminum sheets. Aluminum proves to be a flexible substance with numerous benefits for this particular application. Notably, its lightweight nature, resistance to corrosion, and impressive strength-to-weight ratio make it an ideal choice for securely storing a wide range of chemicals. Moreover, aluminum can be effortlessly molded into various configurations and dimensions, enabling the customization of storage tanks to suit specific needs. Nevertheless, it is crucial to take into account the type and concentration of the chemicals to be stored, as certain substances may potentially react with aluminum. In such instances, it becomes vital to employ appropriate coatings or linings to avert any chemical reactions.

- Q: What are the common sizes of aluminum sheet?

- The sizes of aluminum sheets commonly differ based on specific requirements and industry applications. However, the market offers some standard sizes that are readily available. These sizes typically vary in thickness from 0.025 inches to 0.125 inches and are offered in different widths and lengths. Among the common width options are 36 inches, 48 inches, and 60 inches, while the length can range from 96 inches to 144 inches. Furthermore, smaller sizes like 12 inches by 24 inches or 24 inches by 24 inches can also be found, which are frequently utilized for smaller projects or crafts. It should be noted that specialized aluminum sheet suppliers can provide custom sizes as well.

- Q: whst should I notice while welding aluminum sheet and aluminum block?

- two types of aluminum reach melting points, aluminum block must be preheated when you weld them with small current, you will know how to do it. You can use argon-arc welding back and forth, preheat it with small current.

- Q: How to mix solid aluminium sheet with solid copper sheet (using heat?) to make a compound.

- As copper and aluminum are both metals and both have positive charges, you can not form a compound with them. You can, however, create an alloy out of them.

- Q: Can aluminum sheets be used for air ducts?

- Indeed, air ducts can utilize aluminum sheets. Aluminum, known for its lightweight and durable characteristics, is frequently employed in air ducts. Its resistance to corrosion renders it a suitable option for HVAC systems. Air ducts are often constructed using aluminum sheets due to their malleability, enabling easy bending and shaping to meet specific dimensions. Moreover, aluminum boasts commendable thermal conductivity, ensuring efficient heat transfer within the ducts. Ultimately, opting for aluminum sheets in air ducts proves to be a pragmatic and efficient decision.

- Q: How are aluminum sheets manufactured?

- Aluminum sheets are manufactured through a process called rolling, where aluminum billets are heated and passed through a series of rolling mills to reduce their thickness. The billets are first heated to a specific temperature and then rolled multiple times, with each pass reducing the thickness of the sheet until the desired gauge is achieved. The process also involves annealing, where the sheets are heat-treated to improve their strength and flexibility. Finally, the sheets are cut to the desired length and width before being packaged for distribution.

Send your message to us

Dye Sublimation Prepainted Mill Finished Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords