Big Enamel Prepainted Mill Finished Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

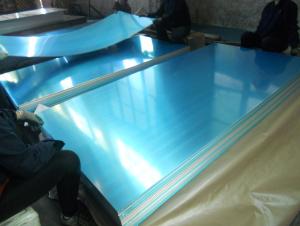

1.Structure of Mill Finished Aluminium Sheet for Prepainted Color

Mill Finished Aluminium Sheet for Prepainted Color is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheet be used for medical applications?

- Yes, aluminum sheet can be used for certain medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various medical devices and equipment. For example, aluminum sheets can be used for manufacturing prosthetic limbs, braces, and orthopedic implants. Additionally, aluminum can be used in the production of medical instruments, such as surgical trays, sterilization containers, and imaging equipment. However, it is important to note that aluminum may not be suitable for all medical applications, as certain medical devices may require specific properties or materials to meet regulatory standards and ensure patient safety. Therefore, the use of aluminum sheet in medical applications should be determined on a case-by-case basis, considering the specific requirements and regulations of each application.

- Q: What are the different surface finishes available for aluminum sheets?

- There are several different surface finishes available for aluminum sheets, each offering distinct characteristics and aesthetic appeal. Some of the commonly used surface finishes for aluminum sheets include: 1. Mill Finish: This is the most basic surface finish and is achieved by leaving the aluminum in its as-rolled condition, without any additional treatment. It has a smooth and shiny appearance, but may have minor imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and provides a wide range of color options. Anodized finishes can have a matte or glossy appearance. 3. Brushed Finish: This finish is achieved by brushing the aluminum sheet with a fine abrasive material, creating a textured pattern. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes and gives a high-end, mirror-like appearance to the aluminum. 5. Embossed Finish: Embossing is a process that creates raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, as it adds texture and visual interest to the material. 6. Powder Coated Finish: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat. This finish provides a durable and weather-resistant coating, and is available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting different patterns or designs on the surface of the aluminum sheet. This finish is often used for architectural applications and adds visual interest to the material. These are just a few examples of the different surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: I broke the swing-arm of a cut-off saw, need to know how to weld it back. I have a stick welder and can weld steel, but have never messed with cast aluminum.

- If it has a silvery-grey appearance and is very light, than it is probably aluminum, especially if you did a spark test and nothing happened(ruling out magnesium, which is unlikely for a random part anyway). Aluminum is alot lighter than steel, if you are holding it you would beable to tell. Magnesium is lighter than aluminum, but will give of red spark when touched with a grinder or shavings are lit. Cast aluminum can be welded with a wire spool gun, any certified aluminum shop(and most welding shops in general) would have one. It can also be Tig welded which would take longer but may yield a better result. *** Do not preheat the aluminum that hot, never preheat it more than 150°F, at 300°F you will start to degrade the aluminum, especially if it is an alloy. Aluminum melts at 1220°F but with preheat it would be possible to exceed that(especially with a spool gun). Do not do multipass beads without allowing it to cool. You will need to clean the oxide off the surface with a stainless steel brush or acid, normal steel will leave impurities that will affect you welding.

- Q: The question asks if it is possible to recycle used aluminum foil to create new aluminum sheets.

- <p>Yes, recycled aluminum foil can be used to make new aluminum sheets. The process involves collecting and sorting the foil, which is then cleaned and melted down. The molten aluminum is poured into molds or rolled into sheets, creating new aluminum products. This recycling method is not only environmentally friendly but also economically viable as it saves energy compared to producing aluminum from raw materials.</p>

- Q: Can aluminum sheet be used for electrical enclosures?

- Yes, aluminum sheet can be used for electrical enclosures. Aluminum is a popular choice for electrical enclosures due to its excellent conductivity, lightweight nature, and corrosion resistance. It provides effective shielding against electromagnetic interference and offers good heat dissipation properties. Additionally, aluminum is easily formable, allowing for the creation of complex shapes and designs. Overall, aluminum sheet is a suitable material for electrical enclosures and is commonly used in various industries including electronics, telecommunications, and power distribution.

- Q: What are the standard tolerances for aluminum sheets?

- The standard tolerances for aluminum sheets vary depending on the specific industry and application. However, some commonly accepted tolerances for aluminum sheets include thickness tolerances, flatness tolerances, and width and length tolerances. Thickness tolerances refer to the allowable variation in the thickness of an aluminum sheet. These tolerances can range from +/- 0.005 inches to +/- 0.010 inches, depending on the grade and thickness of the sheet. Flatness tolerances specify the degree of flatness or deviation from a perfectly flat surface that is acceptable for an aluminum sheet. Flatness tolerances can range from a few thousandths of an inch to a few hundredths of an inch, depending on the specific requirements of the application. Width and length tolerances define the allowable variation in the dimensions of an aluminum sheet. These tolerances can be specified in terms of +/- inches or as a percentage of the sheet's width or length. Generally, width and length tolerances for aluminum sheets are in the range of +/- 0.25 to +/- 0.50 inches. It is important to note that these standard tolerances are subject to change and can vary depending on the specific industry, customer requirements, and the capabilities of the manufacturer. Therefore, it is always recommended to consult the manufacturer or industry-specific standards to determine the precise tolerances for aluminum sheets in a particular application.

- Q: Is it possible to use aluminum sheets for exterior siding purposes?

- <p>Yes, aluminum sheets can be used for siding applications. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and can be painted to match various architectural styles. It's also resistant to rot, termites, and fire, making it a popular choice for many homeowners and builders. However, it's important to ensure that the aluminum is of high quality and installed correctly to maximize its benefits.</p>

- Q: What is the flexural modulus of aluminum sheets?

- The flexural modulus of aluminum sheets refers to the measure of the stiffness or rigidity of the material when subjected to bending or flexural stress. It is a mechanical property that quantifies how well an aluminum sheet can resist deformation under applied force. The flexural modulus of aluminum sheets typically ranges between 69 GPa (gigapascals) to 79 GPa, depending on the specific alloy and temper. However, it is important to note that the flexural modulus can vary slightly based on factors such as thickness, heat treatment, and manufacturing processes. Aluminum is known for its excellent strength-to-weight ratio, making it a popular choice for various applications where lightweight and durable materials are required. Its relatively high flexural modulus allows aluminum sheets to maintain their shape and resist bending or flexing, making them suitable for uses such as aircraft structures, automotive components, and building construction. It is worth mentioning that the flexural modulus of aluminum can be enhanced by alloying elements or through heat treatment processes. For instance, certain aluminum alloys like 7075 or 2024 may exhibit higher flexural modulus values due to their increased strength and stiffness properties. In conclusion, the flexural modulus of aluminum sheets is an important mechanical property that determines their ability to withstand bending or flexural stress. It provides insight into the material's rigidity and helps engineers and designers select the appropriate aluminum alloy and thickness for various applications.

- Q: Can aluminum sheet be used for aircraft skin panels?

- Yes, aluminum sheet can indeed be used for aircraft skin panels.

- Q: Can aluminum sheets be used for architectural sunshades?

- Indeed, architectural sunshades can make use of aluminum sheets. The lightweight property, durability, and resistance to corrosion have rendered aluminum a favored option for sunshades. Furthermore, its high malleability permits the creation of diverse shapes and designs, catering to the architectural aesthetics. By effectively obstructing sunlight and minimizing heat absorption, aluminum sunshades furnish shade and establish a more pleasant atmosphere. Additionally, aluminum qualifies as a sustainable material, effortlessly recyclable, thus qualifying as an environmentally conscious choice for architectural sunshades.

Send your message to us

Big Enamel Prepainted Mill Finished Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords