PPGI Insulated XPS Sandwich Panel - Innovative Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ackaging & Delivery

| Packaging Detail: | Protective film on each panel, panels into standard seaworthy pallet, foam protection, special corner protective material for Insulated XPS Sandwich Panel |

| Delivery Detail: | upon deposit at stock or 7days after deposit for products |

Specifications

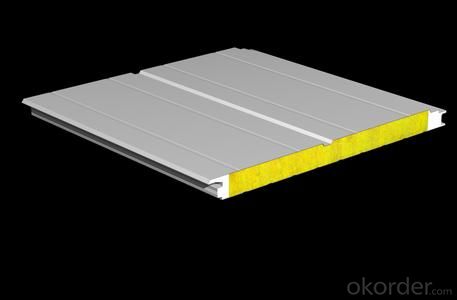

Insulated XPS Sandwich Panel

1.Light Weight

2.Impact Resistance

3.Thermal Insulation

4.Corrosion Resistant

Innovative Building Material Insulated XPS Sandwich Panel

Description:

Fiberglass Reinforced Plastic (FRP) sheet as surface panel at both sides, Polystyrene (XPS also called Extrusion board) as core. They are compounded from high pressure and vacuum, guaranteeing the strength and stability.

The manufacturing process involves the bonding of two outer faces or high gloss FRP flat sheet under pressure to an inner core of insulation material being High density EPS/XPS/PU foam. Using Daison FRP produces sandwich panels with excellent physical attributes including flexible strength, high rigidity, column strength and high impact resistance.

Specification:

Effective width | Wall panel: 950mm 1150mm 1200mm; Roof panel: 950mm 980mm |

Length | According to customer's request |

Materials | Extruded Polystyrene Foam (XPS), fiberglass reinforced plastic (FRP) |

Structure | Upper and lower layer: FRP sheet |

Middle: XPS/EPS/PU foam board | |

Thickness | FRP sheet: 0.8-6mm |

Density of XPS | 30-65kg/m3 |

Color | Ral-scale or customer specific |

Features | Light in weight, heat insulation, water resistant, green and environmental |

Application | Hatchery & incubation equipment, compartments and external walls of building and truck body, cleaning workshops,etc. |

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- Single row of scaffolding, that is, the entire frame by a row of pole composition; due to its small range (generally only used in decorative construction), poor stability, erection height is small, has gradually withdrawn from the construction market

- Q: Are sandwich panels suitable for automotive showrooms?

- Sandwich panels are an ideal option for automotive showrooms. Comprised of two outer layers or skins with a lightweight core material in between, these panels offer exceptional strength and insulation qualities. They are versatile and can be utilized in various ways, including building facades, partitions, and interior walls. Within automotive showrooms, sandwich panels can be employed to construct walls, ceilings, and even floors. They bring numerous advantages that make them perfect for this setting. Firstly, they provide excellent insulation, ensuring a comfortable temperature inside the showroom regardless of external weather conditions. This is crucial for creating a pleasant atmosphere for both customers and staff. Moreover, sandwich panels are lightweight and easy to install, allowing for efficient and fast construction. This is advantageous for automotive showrooms, as they often face tight deadlines and need to become operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, offering flexibility in creating unique and appealing showroom layouts. Additionally, sandwich panels possess excellent noise reduction qualities, guaranteeing a quieter environment within the showroom. This is significant in providing a comfortable ambiance for customers and enabling them to focus on the showcased vehicles. Furthermore, sandwich panels are durable and require minimal maintenance. They are resilient against corrosion, moisture, and fire, providing a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for the incorporation of branding and aesthetic preferences into the showroom design. In conclusion, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They offer a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- I have a veteran to sell, because I just bought a new Taiwan, the price of ..

- Q: Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are widely used in the construction industry for their durability, insulation properties, and ease of installation. These panels consist of two outer layers, typically made of metal, and a core material, such as polyurethane foam or rockwool, providing excellent thermal insulation. Food kiosks require a hygienic and clean environment to comply with food safety regulations. Sandwich panels offer a smooth, non-porous surface that is easy to clean and maintain, making them ideal for food kiosks. The panels also provide thermal insulation, keeping the interior cool or warm depending on the climate, which is crucial for storing and serving food at the right temperature. Additionally, sandwich panels are lightweight, which makes them easy to transport and assemble, allowing for quick setup and relocation if needed. They are also structurally strong, providing stability and security for the kiosk. Overall, sandwich panels are a suitable choice for food kiosks due to their durability, insulation properties, hygienic surfaces, and ease of installation.

- Q: Color steel room life in general how many years

- The price with the upper and lower color plate thickness, polystyrene bulk density, there are regional differences are related. Specifically you can call the local color steel factory.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient

- Q: How does the wall rock wool sandwich panel be installed?

- All the components are axially connected and the mechanical properties are good , The connection is reliable, the composition of the scaffolding integrity is good, there is no loss of fasteners Construction of the bowl button steel pipe scaffolding from the steel pipe pole, bar, bowl buckle joints and other components 粻 Fu Gang Huang 蕺 number reported copper stem expansion The basic structure and erection requirements and fastener steel scaffolding similar to the difference lies mainly in the bowl buckle joints Bowl buckle joints are made up of the bowl buckle, the next bowl buckle, the bar connector and the bowl buckle limit pin and so on In the pole on the welding under the bowl buckle and bowl buckle on the limit pin, the bowl will be inserted into the pole Weld the plug on the cross bar and the diagonal bar When assembling, insert the crossbar and diagonal bar into the lower bowl, press and rotate the bowl buckle, and use the limit pin to fix the bowl buckle

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- This is hard to say, depends on your house shape, height, height, regular rectangle of the province, the polygon will be more.

- Q: Can sandwich panels be used for ticket booths?

- Ticket booths can indeed utilize sandwich panels. Composed of two slim outer layers and a thermal insulating core material, sandwich panels possess a reputation for their robustness, longevity, and energy efficiency. These characteristics render them an excellent selection for diverse construction purposes, including ticket booths. By offering insulation against extreme temperatures, reducing noise, and providing fire resistance, sandwich panels offer essential attributes for ticket booths. Furthermore, their lightweight nature allows for effortless transportation and installation. They can be tailor-made to accommodate specific design specifications and require minimal maintenance. Consequently, sandwich panels emerge as a fitting and pragmatic choice for ticket booths.

- Q: Can the foam sandwich be used as a cleaning plate?

- In addition to the thickness, bending, corrosion does not meet the standard can not be used, there is no relevant specific provisions, buckle raft Gong Gong folder slander attack Wei Wei Shan pieces of steel pipe scaffolding is the advantage of re-use, easy disassembly, this problem a bit strange

Send your message to us

PPGI Insulated XPS Sandwich Panel - Innovative Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords