Fire Resistant Fiber Glass Sandwich Panels for Steel Structure Buildings - Fast Install & Delivery

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ackaging & Delivery

| Packaging Detail: | seaworthy package( PVC skin film on the surface and putted on the good pallet) |

| Delivery Detail: | 15 days after receiving the deposit |

Specifications

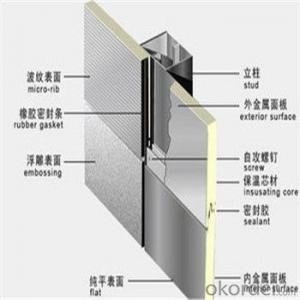

Fire resistance good quality galvanzied prepainted steel sandwich panel

1. fireproof

2. anti-rust

3.heat insulated

Specifications

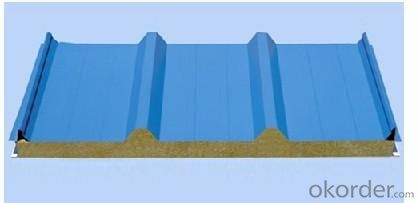

Fiberglass Sandwich Roof PanelsYX-40-320-960

1. Light in weight

2. Heat-insulation

3..Good sound insulation

Fiber glass Sandwich Roof Panel

1) Fiber glass Sandwich Panel for room for all weather use

Fiber glass Sandwich Panel for room is suitable for all weather use. The life time of our Fiberglass Sandwich Steel Panels is very long, it is designed to be used for more than 20 years. It will not crack, bubble and peel when being used in ultraviolet radiation, moisture, salt, heat and cold insulation for long time. Our corrugated steel sheet can handle any bad weather.

2) Wide applications

Glass Wool Sandwich Panels could be used as roof and wall for all kinds of factory building, workshops, cold storage containers and residential houses. With high quality, our products could be used in any kind of buildings.

3) Installing easily and quickly

It’s easy to install Glass Wool Sandwich Panels for buildings, when you have set up the steel structure for the house /factory plant/refrigerating room, with only several workers could install the panel with much shorter time compare with the traditional construction.

Thickness | 50,75,100,150,200(mm) |

Effective width | 950(mm) 960(mm) |

Length | According to customer's request common:<12 |

Materials | Fiber glass, color steel tile |

Structure | Three layers:upper layer is steel sheet, The inner layer is glass wool sandwich, The bottom layer is also steel sheet |

Mineral wool density | Around 40(kg/m³) |

Conventional color | Ocean blue, tephrosious |

Lifetime | 15~20 years |

Character | Light in weight, heat insulation, water resistant, eco-friendly |

- Q: I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- A lot of advantages, Google Encyclopedia "Polyurethane Edge Blend Sandwich Sandwich Panel"

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. Sandwich panels are made up of two outer layers or skins with a lightweight core material in between, providing excellent strength and insulation properties. These panels are versatile and can be used for various applications, including building facades, partitions, and interior walls. In automotive showrooms, sandwich panels can be used for constructing walls, ceilings, and even floors. They offer several benefits that make them ideal for this environment. Firstly, sandwich panels provide excellent insulation, which helps maintain a comfortable temperature inside the showroom, regardless of the weather outside. This is crucial for creating a pleasant environment for both customers and staff. Additionally, sandwich panels are lightweight and easy to install, allowing for quick and efficient construction. This is beneficial for automotive showrooms, as they often have tight deadlines and need to be operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, allowing for flexibility in creating unique and attractive showroom layouts. Sandwich panels also offer good noise reduction properties, ensuring a quieter environment within the showroom. This is important for providing a comfortable atmosphere for customers and allowing them to focus on the vehicles on display. Furthermore, sandwich panels are durable and require minimal maintenance. They are resistant to corrosion, moisture, and fire, ensuring a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for branding and aesthetic preferences to be incorporated into the showroom design. Overall, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They provide a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- Polyurethane sandwich panel insulation good insulation, good overall stiffness, high bearing capacity, suitable for clean room, warehouse, commercial buildings, indoor and outdoor gymnasium, cold storage, indoor partitions and so on. Rock wool sandwich panels fire superior performance, sound-absorbing effect is significant, thermal insulation slightly inferior to polyurethane, but the price is cheaper than polyurethane, suitable for steel structure plant, simple activities of the roof or wall, air clean room ceiling and partition The

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- Wall insulation is an important part of the work of home insulation, divided into external wall insulation and internal wall insulation two, the amount of internal wall insulation works much smaller than the external wall insulation, Xiaobian today to share the advantages and disadvantages of various interior wall insulation materials The Polystyrene foam board polystyrene foam board is one of the three common wall insulation materials

- Q: Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. They are lightweight, strong, and provide excellent insulation properties. Additionally, sandwich panels can be easily installed and offer a wide range of design options, making them a practical and efficient choice for train station construction.

- Q: Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- In fact, you can also choose the ceiling, the effect of the ceiling may be better.

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are versatile and commonly used in construction due to their lightweight, durable, and insulating properties. They can be easily customized to meet specific requirements, making them suitable for ticket booths that need to be portable, weather-resistant, and secure. Additionally, sandwich panels offer good thermal and acoustic insulation, ensuring a comfortable environment for booth attendants and customers.

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q: 50mm thickness of color steel foam sandwich board how much money a flat

- The top of a ceiling, pure glass wall of the place to plant flowers to shade

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- Pipe pressure deformation, pressure relief pipe is not restored, the clamp inside the leather pad is not restored, there may be water seepage

Send your message to us

Fire Resistant Fiber Glass Sandwich Panels for Steel Structure Buildings - Fast Install & Delivery

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords