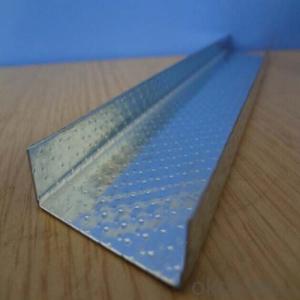

Drywall Steel Profiles Furring Channel Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Drywall Metal Profile

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

commodity | size (mm) | thickness (mm) | length (mm) | pack |

Australia system | ||||

Primary cross rail | 25*21 | 0.55, 0.75,0.85,1.0 | 3600, 4800 | 10 |

Furring channel | 28*38 | 0.55, 0.75,0.85,1.0 | 3000,3600,4800 | 25 |

Wall track | 26*16*26 | 0.45,0.55,0.75 | 3000 | 20 |

Angle | 30*30 | 0.55, 0.75 | 3000 | 50 |

Stud | 51*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 |

64*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

76*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

92*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

Track | 51*32/50 | 0.55, 0.75 | 3000 | 10 |

64*32/50 | 0.55, 0.75 | 3000 | 10 | |

76*32/50 | 0.55, 0.75 | 3000 | 10 | |

92*32/50 | 0.55, 0.75 | 3000 | 10 | |

Middle East system | ||||

Main channel | 38*12 | 0.45,0.50,0.60,0.80,1.0 | 2400,2950,3600 | 20 |

Furring channel | 68*35*12 | 0.40,0.45,0.50,0.60 | 2400,2950,3600 | 25 |

Edge channel | 25*25 | 0.35,0.40,0.45,0.50 | 3000 | 50 |

Stud | 50*34.5 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

70*34.5 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

75*34.5 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*35 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

Track | 52*25 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

72*25 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

76*25 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*25 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

East Europe system | ||||

CD | 60*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 12 |

UD | 28*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 20 |

T-type keel | 20*6 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 |

24*10 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 | |

Stud (CW) | 50*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

70*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*50 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Track (UW) | 52*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

72*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*40 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Light steel keel wall waterproof

- Used to resist external UV radiation, natural aging and chemical corrosion, effectively extend the coating use

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, the gypsum board partition wall is not much weight, far less than the prefabricated board capacity

- Q: Light steel keel wall and wood which low cost

- Should be a wooden keel, the general family decoration with a wooden keel on it, wood keel cost is low, to meet the family use, light steel keel cost high, but high strength. It is recommended to use wood keel

- Q: Light steel keel + gypsum board wall and other wall joints how to strengthen?

- Are generally used to deal with the patch to prevent brushing latex paint. But if your partition wall area is relatively large, it is recommended that you do not specifically and do not do with other walls, leaving 3-5mm edge, or posted a long time can not guarantee no cracking.

- Q: Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- Light steel keel light steel keel easy to install, suitable for office, plant and so on.

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- In order to be able to make decoration more perfect, it is recommended that you choose the decoration manufacturers, to be careful, we must choose the same brand of all products. The

- Q: Light steel keel wall gypsum board seams how to deal with? Including smallpox

- White is the hook agent, the tape is anti-crack tape, paste the back after the brush can prevent the latex paint.

- Q: Light steel keel gypsum board wall panels have cracks how to do?

- Repair with glass fiber gypsum

- Q: Light steel keel partition wall construction process is what

- (1) Pin line, sub-file: in the partition with the upper and lower and the two sides of the matrix at the junction, should be the width of the keel line. Battle clear, accurate location. According to the design requirements, combined with the cover panel of the long and wide sub-file to determine the vertical keel; transverse and additional keel position. (2) for the pillow: when the design requirements, according to the design requirements for the concrete pillow. For the pillow should be supporting mold, bean stone concrete should be pound dense. (3) fixed along the edge, along the keel; along the line position fixed along the edge, along the keel, can be fixed with nails or expansion bolts, fixed point spacing should not be greater than 600mm, keel docking should remain straight.

- Q: Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Benzene board and extruded board can be, are more suitable for home improvement. I do with the noise is extruded board than the benzene board sound insulation is also very good environmental protection

Send your message to us

Drywall Steel Profiles Furring Channel Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords