Poly Aluminum Coil C83868 - Direct Rolled Aluminum Coil for Architecture China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Direct Rolled Aluminum Coil for Architechture China Supply

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Direct Rolled Aluminum Coil for Architechture China Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Direct Rolled Aluminum Coil for Architechture China Supply

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

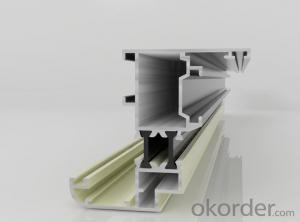

5. Image of Direct Rolled Aluminum Coil for Architechture China Supply

6. Package and shipping of Direct Rolled Aluminum Coil for Architechture China Supply

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different grades of aluminum used in coil manufacturing?

- The different grades of aluminum commonly used in coil manufacturing include 1100, 3003, and 5052. These grades vary in their chemical composition, mechanical properties, and suitability for various applications.

- Q: Are aluminum coils suitable for coil slitting applications?

- Yes, aluminum coils are suitable for coil slitting applications. Aluminum is a lightweight, versatile, and corrosion-resistant material that can be easily slit into narrow strips without compromising its structural integrity. Aluminum coils are commonly used in various industries such as automotive, construction, and packaging, where precise and narrow strips are required for specific applications. Additionally, aluminum coils offer excellent formability and surface quality, making them suitable for coil slitting processes that require high precision and consistency.

- Q: Is it advisable to use a hammer to open a stuck aluminum coil?

- <p>Using a hammer to break open an aluminum coil that is stuck closed is not recommended. Aluminum is a soft metal and can be easily damaged by blunt force. Instead, try using pliers or a screwdriver to gently pry open the coil. If the coil is rusted or stuck due to other reasons, applying a penetrating oil or lubricant might help loosen it without causing damage. Always prioritize safety and the preservation of the material when attempting to open or unstick objects.</p>

- Q: Can aluminum coils be used in the production of electrical conductors?

- Yes, aluminum coils can be used in the production of electrical conductors. Aluminum is a highly conductive metal and is commonly used in various electrical applications due to its lightweight, cost-effectiveness, and excellent electrical conductivity.

- Q: How are aluminum coils used in the production of heat exchangers?

- Aluminum coils play a crucial role in the production of heat exchangers. Heat exchangers are devices used to transfer heat between two or more fluids, allowing for efficient heating or cooling in various applications. The use of aluminum coils in heat exchanger production is primarily due to the unique properties of aluminum. Firstly, aluminum is an excellent conductor of heat. It possesses a high thermal conductivity, which means it can efficiently transfer heat from one fluid to another. This property is particularly important in heat exchangers, as it ensures that the heat exchange process is rapid and efficient. Secondly, aluminum is lightweight and has a high strength-to-weight ratio. This makes it an ideal choice for heat exchangers, as it allows for the production of compact and lightweight units that can be easily installed in various systems. The lightweight nature of aluminum coils also reduces the overall weight of the heat exchanger, which can be advantageous in applications where weight is a concern, such as automotive or aerospace industries. Additionally, aluminum coils have excellent corrosion resistance. Aluminum naturally forms a thin oxide layer on its surface, which protects it from corrosion. This resistance to corrosion is vital in heat exchangers, as they often come into contact with different fluids that may be corrosive. The use of aluminum coils ensures the longevity and durability of the heat exchanger, preventing premature failure or damage. Moreover, aluminum coils are highly malleable and can be easily formed into different shapes and sizes. This flexibility in manufacturing allows for the production of customized heat exchangers that can be tailored to specific applications and requirements. The ability to shape aluminum coils also facilitates the design of complex heat exchanger geometries, maximizing the heat transfer surface area and enhancing overall performance. In summary, aluminum coils are extensively used in the production of heat exchangers due to their high thermal conductivity, lightweight nature, corrosion resistance, and malleability. These properties make aluminum an ideal material for efficient heat transfer, compact designs, durability, and customization. Overall, aluminum coils contribute significantly to the effectiveness and reliability of heat exchangers in various industries and applications.

- Q: How are aluminum coils protected against transportation damage?

- Aluminum coils are protected against transportation damage through various measures implemented by manufacturers and transportation companies. First and foremost, aluminum coils are usually packaged and stored in sturdy crates or pallets that provide a protective barrier against external impact and ensure stability during transit. These crates are often made of wood or metal and are designed to withstand the rigors of transportation. To further safeguard against damage, the coils are often wrapped in protective materials such as plastic or stretch film. This additional layer of packaging helps to prevent scratches, abrasions, and moisture damage during handling and transportation. The coils may also be secured within the crates or pallets using straps or bands to prevent movement and potential impact with other objects. Furthermore, manufacturers often utilize padding materials such as foam or cardboard inserts to create a cushioning effect within the packaging. These inserts help absorb shock and vibration during transit, reducing the risk of damage caused by impacts or sudden movements. Additionally, transportation companies play a crucial role in ensuring the safe transportation of aluminum coils. They employ specialized handling equipment such as forklifts or cranes to minimize the risk of mishandling and dropping the coils. Moreover, they carefully load and secure the coils within shipping containers or trucks, ensuring they are properly braced and immobilized to prevent shifting or rolling during transportation. In summary, aluminum coils are protected against transportation damage through the use of sturdy packaging, protective wraps, padding materials, and appropriate handling techniques. These measures aim to minimize the risk of scratches, dents, and other forms of damage caused by impacts, vibrations, or mishandling during transit.

- Q: Can aluminum coils be utilized as an insulating material?

- <p>Aluminum coils are not typically used for insulation. They are good conductors of heat and electricity, which makes them unsuitable for insulation purposes. Insulation materials should be poor conductors to prevent the flow of heat or electricity. Aluminum coils are more commonly used in applications where conductivity is desired, such as in electrical wiring or heat exchangers. For insulation, materials like fiberglass, mineral wool, or plastic foams are used because they resist heat flow effectively.</p>

- Q: Are aluminum coils suitable for marine applications?

- Yes, aluminum coils are suitable for marine applications. Aluminum is a corrosion-resistant material, making it an excellent choice for use in marine environments where exposure to saltwater and other corrosive elements is common. Aluminum coils are lightweight, durable, and have high strength-to-weight ratio, which is important for marine applications where weight reduction is desired. Additionally, aluminum coils can withstand extreme temperatures and have good thermal conductivity, making them suitable for various marine heating and cooling systems. Overall, aluminum coils are a popular choice in marine applications due to their corrosion resistance, durability, and lightweight properties.

- Q: Can aluminum coils be used in the production of architectural panels?

- Yes, aluminum coils can be used in the production of architectural panels. Aluminum is a popular material for architectural panels due to its lightweight, durability, and versatility. Aluminum coils can be easily shaped, cut, and formed into various panel designs, making them suitable for a wide range of architectural applications.

- Q: Can aluminum coils be used in vacuum applications?

- Indeed, aluminum coils are capable of being employed in vacuum applications. Aluminum, being a frequently utilized substance in vacuum systems, possesses exceptional attributes including low outgassing, high thermal conductivity, and commendable corrosion resistance. Consequently, these qualities render aluminum coils suitable for a diverse array of vacuum applications, encompassing, but not restricted to, vacuum chambers, vacuum pumps, cryogenic systems, and particle accelerators. Nevertheless, it is crucial to acknowledge that aluminum may react with particular gases or chemicals. Hence, it is imperative to carefully evaluate the specific necessities and compatibility of the vacuum application prior to employing aluminum coils.

Send your message to us

Poly Aluminum Coil C83868 - Direct Rolled Aluminum Coil for Architecture China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords