Tk 6491509001742 AA3003 H12 Direct Rolled Aluminum Coil China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of AA3003 H12 Direct Rolled Aluminum Coil China Supply

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of AA3003 H12 Direct Rolled Aluminum Coil China Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of AA3003 H12 Direct Rolled Aluminum Coil China Supply

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

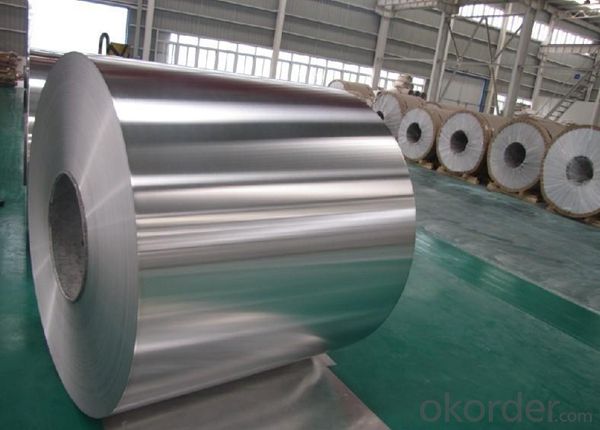

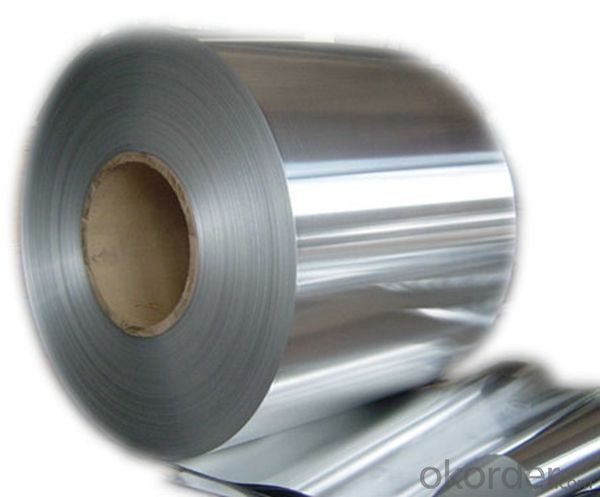

5. Image of AA3003 H12 Direct Rolled Aluminum Coil China Supply

6. Package and shipping of AA3003 H12 Direct Rolled Aluminum Coil China Supply

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils joined together to form larger panels?

- Coil joining or coil-to-panel joining is the technique employed to combine aluminum coils into larger panels. To accomplish this, aluminum coils are fed into a coil joining machine, specifically designed for seamless connection of multiple coils. To initiate the process, the individual coils are inserted into the machine. The machine then unwinds the coils and brings them together, aligning them side by side. Typically, the edges of the coils slightly overlap to ensure a secure and uninterrupted connection. Once aligned, the machine implements various methods to bond the coils together. One prevalent approach involves the application of heat and pressure. By heating the overlapping edges of the coils, the aluminum softens and fuses together. Simultaneously, pressure is applied to ensure a robust bond. Alternatively, mechanical fasteners can be utilized to join the aluminum coils. In this case, the machine punches holes through the overlapping edges and inserts fasteners, such as screws or rivets, for a secure hold. Following the joining process, the machine continues to feed the connected coils forward, facilitating continuous production of larger panels. Excess material from the overlapping edges is typically trimmed off, resulting in a sleek and seamless panel. Overall, precision and specialized machinery are essential for the process of joining aluminum coils to create larger panels. The resulting panels possess durability, lightweight properties, and find widespread application in industries such as construction, automotive, and aerospace.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing spring steel wire coils.

- <p>Spring steel wire coils offer several advantages such as high strength and durability, making them ideal for applications requiring resilience and resistance to deformation. They are also known for their excellent elasticity, which allows for consistent performance in dynamic applications. Additionally, spring steel wire coils can be easily formed into various shapes, providing versatility in design and functionality. However, they also have disadvantages, including potential for corrosion if not properly treated, and they can be more expensive than other types of wire due to the material's properties. Furthermore, spring steel wire coils may require specialized tools and equipment for handling and installation, adding to the cost and complexity of their use.</p>

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum's low coefficient of friction and excellent thermal conductivity make it a suitable material for various applications where low friction is desired, such as in sliding mechanisms, bearings, and electrical connectors.

- Q: What are the benefits of using aluminum coils?

- There are several benefits of using aluminum coils. Firstly, aluminum is a lightweight material, making it easier to handle and install. Secondly, aluminum is highly resistant to corrosion, ensuring the durability and longevity of the coils. Additionally, aluminum coils have excellent heat transfer properties, allowing for efficient cooling or heating. Lastly, aluminum is a sustainable and recyclable material, making it an environmentally friendly choice.

- Q: What are the factors that affect the cost of aluminum coils?

- There are several factors that can affect the cost of aluminum coils. 1. Raw material costs: The cost of aluminum, which is the primary material used in manufacturing coils, can fluctuate based on global supply and demand as well as market conditions. Changes in the price of aluminum can have a direct impact on the cost of aluminum coils. 2. Manufacturing process: The production process involved in making aluminum coils can also impact their cost. Various techniques such as casting, rolling, and annealing are used, and each method has its own associated costs. The complexity and efficiency of the manufacturing process can influence the final price of the coils. 3. Size and specifications: The size, thickness, and specifications of the aluminum coils can affect their cost. Larger coils or coils with specific dimensions may require additional raw materials, processing time, or specialized equipment, which can contribute to higher costs. 4. Surface finish: The type of surface finish applied to the aluminum coils can also impact their cost. Coils with a higher-quality finish, such as brushed or coated surfaces, may be more expensive due to the additional processing and materials required. 5. Quantity and order volume: The volume of aluminum coils ordered can often impact the cost. Larger order quantities may lead to economies of scale, resulting in lower unit costs. Conversely, smaller orders or customized specifications may incur additional setup costs or higher per-unit prices. 6. Market competition: The level of competition in the aluminum coil industry can affect pricing. If there are numerous manufacturers offering similar products, prices may be more competitive as companies strive to attract customers. On the other hand, if there are limited suppliers or unique product offerings, prices may be higher due to reduced competition. 7. Transportation and logistics: The cost of transporting aluminum coils can also influence their overall price. Factors such as distance, mode of transportation, and fuel prices can impact shipping costs, which in turn can be passed on to customers. It is important to note that these factors are not exhaustive and can vary depending on the specific circumstances and market dynamics. Additionally, other external factors such as taxes, tariffs, and government regulations can also affect the cost of aluminum coils.

- Q: What is the typical warranty period for aluminum coils?

- The typical warranty period for aluminum coils can vary depending on the manufacturer and the specific product. However, in general, aluminum coils tend to have warranty periods ranging from 5 to 10 years. This means that during this time, the manufacturer will cover any defects or issues that may arise with the aluminum coils. It is important to note that some manufacturers may offer extended warranty options for an additional cost. Additionally, it is advisable to check the warranty terms and conditions provided by the manufacturer as they may have specific requirements or limitations for the warranty to be valid.

- Q: I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- Well using aluminum heads would be enough to justify doing it because i have aluminum heads and im at 11:1 compression. These heads are 9.5:1 compression with 11:1 compression with twin turbos. Now you are running with straight motor and shoud be fine. Now if you are going to get that pony a supercharger I would suggest getting cast iron heads with a chrome finish to manage this power gain. I have had these for about 40K miles and are still fine. I will eventually change to cast iron with a chrome finish. Hope this helps.

- Q: How are aluminum coils used in solar panels?

- Aluminum coils are used in solar panels as part of the construction and structure of the panel. They are used to hold the solar cells in place and provide a sturdy framework for the overall structure. Additionally, aluminum coils help with heat dissipation and ensure efficient functioning of the solar panel by preventing warping or damage caused by temperature fluctuations.

- Q: How do aluminum coils withstand extreme weather conditions?

- Due to the unique properties of aluminum, aluminum coils can endure harsh weather conditions. Firstly, aluminum's lightweight nature allows it to remain flexible and resistant to bending or warping when faced with strong winds or heavy snow loads. As a result, aluminum coils are less likely to be damaged during extreme weather events like hurricanes or blizzards. Moreover, aluminum possesses a high resistance to corrosion. When exposed to air, it forms a protective oxide layer on its surface, preventing rusting or deterioration caused by moisture or severe weather conditions. This protective layer acts as a barrier against elements such as rain, snow, or saltwater, making aluminum coils highly durable and long-lasting. Additionally, aluminum exhibits high thermal conductivity, enabling it to efficiently dissipate heat. This property ensures that aluminum coils effectively transfer heat away from the system, preventing overheating and potential damage during hot weather conditions. Furthermore, the efficient dissipation of heat contributes to the energy efficiency of aluminum coils. Lastly, aluminum is a non-magnetic material, rendering it unaffected by electromagnetic interference or lightning strikes. This quality makes aluminum coils safe and dependable in areas prone to electrical storms or high levels of electromagnetic activity. To summarize, aluminum coils are designed to endure extreme weather conditions due to their lightweight, corrosion-resistant, thermally conductive, and non-magnetic properties. These characteristics make aluminum coils highly durable, dependable, and suitable for various applications, including HVAC systems, automotive cooling, and electrical wiring.

- Q: Is it possible to utilize aluminum coils in the production of baking pans or trays?

- <p>Yes, aluminum coils are commonly used for making baking pans and trays due to their excellent heat conductivity, lightweight, and durability. Aluminum's non-reactive nature also makes it safe for food contact. However, it's crucial to ensure that the aluminum is food-grade and that the manufacturing process adheres to safety standards to prevent any health risks.</p>

Send your message to us

Tk 6491509001742 AA3003 H12 Direct Rolled Aluminum Coil China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords