Aluminum Coil Roll AA1050 H12 Direct Rolled Aluminum Coil China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of AA1050 H12 Direct Rolled Aluminum Coil China Supply

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of AA1050 H12 Direct Rolled Aluminum Coil China Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of AA1050 H12 Direct Rolled Aluminum Coil China Supply

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

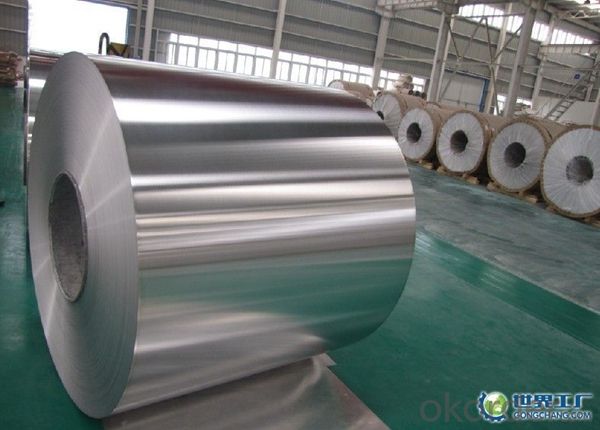

5. Image of AA1050 H12 Direct Rolled Aluminum Coil China Supply

6. Package and shipping of AA1050 H12 Direct Rolled Aluminum Coil China Supply

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What’s the standard of tensile strength and ductility of aluminum coil 3003?

- Detailed description can help resolve problems quickly. Performance and status is a related. As aluminum coil is usually semi-hard, the tensile strength is greater than or equals 150, ductility is greater than or equals 12.

- Q: What is color aluminum coil?

- The base plates are all aluminum, but the surface has been colored.

- Q: Related technical standards of aluminium coil

- GB/T 10456-1989 anodized aluminium foilGB/T 9734-1988 chemical reagent -- General method for the determination of aluminiumGeneral specification for GB/T 9538-1988 strip cable connectorsComplexometric titration fluoride release method for the determination of three aluminium oxide content in GB/T 9489.4-1988 corundum powder twoGB/T 9438-1999 aluminium alloy castingsGB/T 8733-2000 cast aluminium alloy ingotsGB/T 6454-1986 getter aluminium zirconium alloy rings and sheets

- Q: is Aluminum wrotten with a 2 behnd it?

- Aluminum is not a diatomic atom, which is to say, in it's equilibrium state it has only one atom, written Al. As an ion, aluminum has a charge of 3+, and may have a subscript of 2 when written in an ionic formula (i.e., aluminum oxide: Al2O3).

- Q: Can aluminum coils be used in the production of cookware?

- Certainly, cookware production can involve the utilization of aluminum coils. Aluminum stands out as a favored material for cookware owing to its exceptional heat conductivity and lightweight properties. Employing aluminum coils enables manufacturers to effortlessly mold and fashion cookware into diverse dimensions and contours. Furthermore, aluminum exhibits resistance against rust and corrosion, rendering it appropriate for prolonged kitchen use. Nevertheless, it is crucial to acknowledge that aluminum cookware should possess a non-stick coating or undergo anodization to avert any plausible interaction between the aluminum and food, as excessive aluminum consumption can be detrimental to one's health.

- Q: Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications. Aluminum is known for its excellent thermal conductivity, which means it is highly effective in transferring heat. Aluminum coils are commonly used in various heat transfer applications such as air conditioning systems, refrigeration units, and heat exchangers. The lightweight and corrosion-resistant properties of aluminum also make it a popular choice for these applications. Additionally, aluminum coils can be easily shaped and formed, allowing for efficient heat transfer in complex systems.

- Q: Can aluminum coils be customized according to specific requirements?

- Yes, aluminum coils can be customized according to specific requirements. Aluminum coils can be tailored to meet specific dimensions, thicknesses, and finishes to suit various applications. Customization options can include specific alloys, tempering processes, and even specialized coatings to enhance corrosion resistance or improve appearance. Additionally, aluminum coils can be fabricated with specific features such as perforations, embossing, or edge treatments to meet specific functional or aesthetic requirements. With the ability to be customized, aluminum coils offer flexibility and versatility for a wide range of industries and applications.

- Q: Is it possible to customize the dimensions of aluminum coils?

- Indeed, the dimensions of aluminum coils can be tailored to suit individual preferences. Customers are able to request and obtain aluminum coils that have been manufactured and trimmed to specific measurements in accordance with their particular requirements and specifications. This customization procedure entails the meticulous cutting and molding of the aluminum coil in order to achieve the desired dimensions. This capability offers versatility across a range of industries and applications, where precise coil sizes are indispensable. By customizing the dimensions of aluminum coils, they become perfectly compatible with various production procedures, machinery, or end-use applications.

- Q: Can aluminum coils be used in high-altitude environments?

- Yes, aluminum coils can be used in high-altitude environments. Aluminum is known for its lightweight and corrosion-resistant properties, which make it suitable for various applications, including those in high-altitude environments. Additionally, aluminum has a high strength-to-weight ratio, allowing it to withstand the challenges posed by high altitudes.

- Q: What is the purpose or use of aluminum coil in various applications?

- <p>Aluminum coil is a versatile material used in a wide range of applications due to its properties such as lightweight, corrosion resistance, and high thermal and electrical conductivity. It is commonly used in construction for roofing and siding, in the manufacturing of heat exchangers and radiators, and in electrical applications like transformers and power lines. Aluminum coil is also utilized in packaging, such as food and beverage cans, and in automotive and aerospace industries for lightweight components. Its malleability allows it to be easily shaped and formed, making it an ideal material for various industrial processes.</p>

Send your message to us

Aluminum Coil Roll AA1050 H12 Direct Rolled Aluminum Coil China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords