Aluminum Steel Coils for Ceiling, Building Material in Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | Standard seaworthy packing for long distance transportation |

| Delivery Detail: | in 25-30 days upon the receipt of original L/C or 30% deposit |

Product Description

Specifications

Material | 1, 2, 3, 5, 6, 7, 8 Series |

Temper | O, F, H14, H34, H32, H112, T4, T6 |

Surface treatment | Mill Finish, Anodized, Electroplates, Powder Coated, Wooden Finish, Polished |

Color | Plain, Silver, Black, Red, Blue, or as required |

Length | 1000mm~6000mm, or as required |

Shape | Plain, bossed, or as per the drawings and samples |

Fabrication | Cutting, drilling, punching, bending, etc |

Tolerances | As per your requirements |

Package | inner plastic paper interleaving each piece profile, outer fixed by plywood; or customized. |

Payment terms | T/T or L/C at sight |

Price terms | FOB; CIF |

Delivery time | 15~20 days after order confirmation |

Certification | ISO 9001:2008; SGS |

Application | Decorations, Fence, Building, Aviation industry, Mechanical equipment |

Capacity | 5000 tons per month |

MOQ | 1 Metric ton

|

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

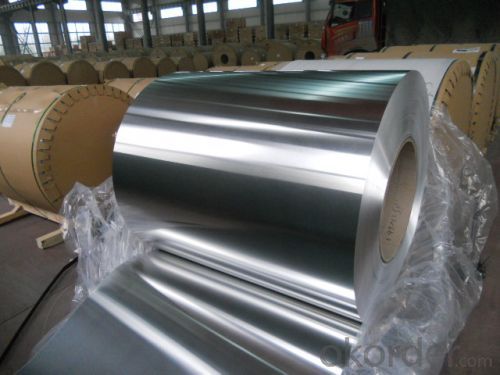

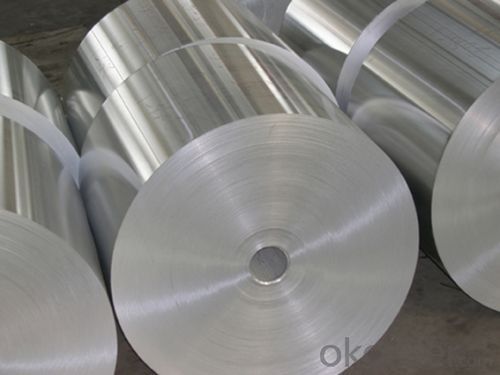

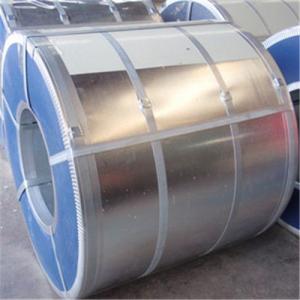

Photos

- Q: I am wondering if a deodorant made with aluminum silicate is safer than one with aluminum salt.

- aluminum silicates have been used in deodorants for years. there was a time when it was thought that the Al in the deodorants was causing alzheimers but that has been shown to be wrong. if there are other dangers to the silicates, we haven't found them or they aren't that bad

- Q: Are there any limitations on the bending or shaping of aluminum coils?

- Yes, there are limitations on the bending or shaping of aluminum coils. Aluminum is a relatively soft and malleable metal, which makes it suitable for bending and shaping. However, it does have some limitations. Firstly, the thickness of the aluminum coil can affect its bendability. Thicker aluminum coils are generally more difficult to bend or shape compared to thinner ones. This is due to the increased resistance to deformation in thicker materials. Secondly, the temper or hardness of the aluminum coil can also impact its bendability. Different tempers, such as soft, half-hard, or hard, have varying degrees of malleability. Soft tempers are easier to bend, while harder tempers require more force and may be prone to cracking or breaking during bending. Additionally, the design and complexity of the desired bend or shape can also impose limitations. Sharp bends or complex shapes may cause the aluminum coil to crack or deform, especially if it is not properly supported or if the bending radius is too small. Lastly, the presence of any impurities, defects, or alloying elements in the aluminum coil can affect its bendability. These factors can lead to inconsistencies in the material's mechanical properties, making it more prone to cracking or breaking during bending or shaping. Therefore, while aluminum coils offer flexibility for bending and shaping, it is important to consider the thickness, temper, design, and quality of the material to ensure successful and safe manipulation.

- Q: Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications due to their excellent thermal conductivity properties.

- Q: Is it safe and effective to use an electric stove to heat an aluminum coil?

- <p>Yes, you can use an electric stove to heat an aluminum coil. Aluminum is a good conductor of heat, so it will heat up when placed on an electric stove. However, it's important to ensure the coil is clean and free of any non-stick coatings that could be damaged by high heat. Also, be cautious of the temperature settings on your stove, as aluminum can melt at high temperatures. Always monitor the coil to prevent overheating or fire hazards.</p>

- Q: Can aluminum coils be used in the production of electrical enclosures?

- Yes, aluminum coils can be used in the production of electrical enclosures. Aluminum is a popular choice for manufacturing electrical enclosures due to its excellent conductivity, lightweight nature, and corrosion resistance. The use of aluminum coils allows for the production of seamless and sturdy enclosures, ensuring efficient heat dissipation and protection for electrical components. Additionally, aluminum coils can be easily molded and formed into various shapes and sizes, providing flexibility in design. Overall, the use of aluminum coils in the production of electrical enclosures is a reliable and cost-effective solution.

- Q: When aluminum metal is heated with an element from group VIA of the periodic table, an ionic compound forms. When the experiment is performed with an unknown croup VIA element, the product is 18.56% Al by mass. What is the formula of the compound and what is its name?

- Let's say you have l00 grams of this compound, so inside the compound would be l8.56 grams of Aluminum and the remaining. 81.44 grams of the second element. Elements in group 6A have 6 electrons in their outer shell and an oxidation # of -2 and the formula for the compound would be Al2X3. a 2mole Al to 3 mole X ratio. The compound would have the atom ratio of Al2X3 derived from the valences of +3 and -2. So the two aluminum atoms in the compound would be providing a total mass of l8.56 grams and the three atoms of X would be providing the remaining mass of 81.44 g so we have the ratio. l8.56 g Al/ 2 Al moles = 81.44 grams element X/ 3 moles X The mass ratio between these two elements is 8l.44 over l8.56 or 4.38 to l The atomic wt. total for 2 aluminum atoms is 54 so the atomic wtl total for three atoms of element X should be 4.38 times 54 which is 236.9 Now if we divide 236.9 by three atoms of X in the compound we get an atomic wt. of 78.9 which corresponds to Selenium So the compound is Al2Se3. This was a challenging problem, congratulations to your chem teacher.!!!

- Q: Are aluminum coils more expensive than other coil materials?

- It depends on the specific material being compared. Generally, aluminum coils tend to be more expensive than some other coil materials, such as copper or steel. However, the cost can vary depending on factors like the coil size, thickness, and supplier.

- Q: Can aluminum coils be used in food processing applications?

- Food processing applications can utilize aluminum coils, as they offer a range of advantages. Aluminum is a widely used and highly adaptable material in the food industry due to its various benefits. Aluminum coils are lightweight, durable, and possess excellent thermal conductivity, which makes them suitable for applications requiring efficient and uniform heat transfer. When it comes to food processing, aluminum coils are commonly employed in equipment such as heat exchangers, evaporators, and refrigeration units. These coils help to cool, heat, or maintain the temperature of different food products during their processing, storage, or transportation. The exceptional thermal conductivity of aluminum ensures that heat is evenly dispersed, thereby aiding in the preservation of food quality and flavor. Furthermore, aluminum is a non-toxic and non-reactive metal, meaning it has no adverse effects on the taste or composition of the processed food. It is also naturally resistant to corrosion, ensuring that the coils do not contaminate the food and can be easily cleaned and maintained. In addition, aluminum is an environmentally friendly and recyclable material, aligning with the increasing demand for sustainable practices in the food industry. Its lightweight nature also contributes to energy efficiency and reduced transportation expenses. In conclusion, aluminum coils are a reliable, efficient, and safe choice for food processing applications. They meet the strict requirements of the industry while ensuring the quality and safety of the processed food.

- Q: I have aluminum windows that have to be replaced due to bad thermopanes - there is accumulated grime and humidity in between the panes. Is it possible to buy individual custom-sized replacements or do I have to get all new windows and frames? Any referrals would be helpful.

- you can just get the panes cleaned and restored you could even do it yourself, they are just two sheets of glass stuck to a frame

- Q: Is it possible to utilize a magnetic stirrer to determine the magnetic characteristics of an aluminum coil?

- <p>No, you cannot use a magnetic stirrer to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not respond to magnetic fields in the way magnetic materials like iron, nickel, or cobalt do. A magnetic stirrer operates by creating a rotating magnetic field to stir substances, but since aluminum is non-magnetic, it will not be affected by the stirrer's field. To test magnetic properties, you would need to use materials that are ferromagnetic or paramagnetic, or employ other methods such as a magnetometer for measuring magnetic fields.</p>

Send your message to us

Aluminum Steel Coils for Ceiling, Building Material in Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords