Brushed Gold Anodized Direct Casting Mill Finished Aluminium Strips AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

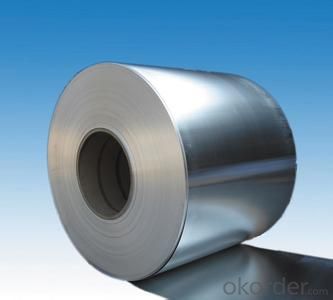

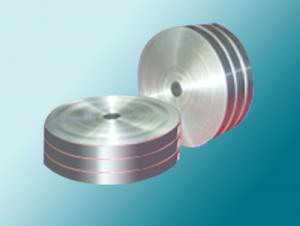

1.Structure of Direct Casting Mill Finished Aluminium Strips AA3003

Direct Casting Mill Finished Aluminium Strips AA3003 are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Direct Casting Mill Finished Aluminium Strips AA3003

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Direct Casting Mill Finished Aluminium Strips AA3003

4. Product Specification of Direct Casting Mill Finished Aluminium Strips AA3003

| Alloy | Temper | Rolling | Thickness | Width |

| AA3003 | F | Hot Rolled | 0.2MM-2MM | 1000MM-1500MM |

5.FAQ of Direct Casting Mill Finished Aluminium Strips AA3003

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: what's the difference between the knocking voice of aluminum sheet and stainless steel?

- The voice of aluminum sheet is toneless, and the voice of stanless steel is more crisp.

- Q: Are aluminum sheets suitable for interior design applications?

- Yes, aluminum sheets are suitable for interior design applications. Aluminum is a versatile and durable material that can be used in various ways to enhance the aesthetics of interior spaces. It can be easily shaped, cut, and manipulated to create unique and modern designs. Aluminum sheets are available in different finishes, such as brushed, polished, or textured, which allows for a wide range of design possibilities. One of the main advantages of using aluminum sheets in interior design is their lightweight nature. This makes them easy to handle and install, reducing labor and transportation costs. Additionally, aluminum is resistant to corrosion, making it suitable for areas with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets can be used for various applications in interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. They can be painted or coated in different colors to match any interior design scheme. Aluminum sheets can also be perforated or engraved to create patterns or intricate designs, adding a unique visual appeal to the space. Furthermore, aluminum is a sustainable material as it is highly recyclable. Its recycling process requires only a fraction of the energy needed to produce new aluminum, making it an eco-friendly choice for interior design applications. In conclusion, aluminum sheets are highly suitable for interior design applications due to their versatility, durability, lightweight nature, resistance to corrosion, and ability to be shaped and manipulated. They offer a wide range of design possibilities and can be used for various applications, making them a popular choice among designers and architects.

- Q: Explain the pros and cons of utilizing aluminum sheets in the construction of car body panels.

- <p>Aluminum sheets offer several advantages for car body panels, such as reduced weight, which can improve fuel efficiency and handling. They also have high resistance to corrosion, enhancing the vehicle's durability. Additionally, aluminum is easier to recycle, contributing to environmental sustainability. However, there are downsides, including higher cost compared to steel, which can affect the vehicle's price. Aluminum is also less malleable, making it more challenging to repair after accidents, potentially leading to higher repair costs. Furthermore, aluminum's lower strength compared to steel can necessitate thicker panels to achieve the same structural integrity, which may offset some of the weight savings.</p>

- Q: What are the different types of aluminum sheets available in the market?

- There are several different types of aluminum sheets available in the market, each with its own unique characteristics and applications. Some of the most common types include: 1. Plain Aluminum Sheet: This is the most basic and widely used type of aluminum sheet. It is known for its excellent corrosion resistance and high strength-to-weight ratio. Plain aluminum sheets are commonly used in construction, automobile manufacturing, and aerospace industries. 2. Painted Aluminum Sheet: These sheets are coated with a layer of paint to enhance their aesthetic appeal and protect the underlying aluminum from environmental elements. Painted aluminum sheets are commonly used in architectural applications, signage, and decorative purposes. 3. Perforated Aluminum Sheet: This type of aluminum sheet features perforations or holes throughout its surface. It is often used in architectural projects, industrial filtration systems, and ventilation applications. 4. Embossed Aluminum Sheet: These sheets have a textured or patterned surface, created by embossing or rolling the aluminum. Embossed aluminum sheets are frequently used for decorative purposes, such as interior design, signage, and packaging. 5. Anodized Aluminum Sheet: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum. Anodized aluminum sheets are highly resistant to corrosion and abrasion, making them suitable for outdoor applications, such as building facades and automotive parts. 6. Tread/Diamond Plate Aluminum Sheet: This type of aluminum sheet features raised diamond or tread patterns on its surface, providing enhanced grip and traction. Tread/diamond plate aluminum sheets are commonly used in transportation, flooring, and staircases. Additionally, aluminum sheets are available in various thicknesses, sizes, and alloys, such as 3003, 5052, and 6061. The specific type of aluminum sheet required depends on the intended use and specific requirements of the project.

- Q: How do you remove stains or marks from aluminum sheets?

- To effectively eliminate stains or marks on aluminum sheets, the following steps can be followed: 1. Begin by preparing a mixture of warm water and mild dish soap in a bucket or basin. 2. Immerse a soft cloth or sponge into the soapy water and gently scrub the affected area. It is important to avoid the use of abrasive materials or harsh chemicals that may cause scratches or damage to the aluminum surface. 3. In case of more stubborn stains, a paste can be created by combining baking soda with water. Apply the paste onto the stained area and allow it to sit for a few minutes before softly scrubbing it with a cloth or sponge. 4. If the stains persist, consider utilizing a non-abrasive cleaner specifically designed for aluminum surfaces. Adhere to the instructions provided by the manufacturer on the packaging for optimal outcomes. 5. Thoroughly rinse the aluminum sheet with clean water to eliminate any remnants of soap. 6. For particularly stubborn stains or marks that prove to be difficult to remove, white vinegar or lemon juice can be employed. Apply a small amount of vinegar or lemon juice onto a cloth or sponge and gently rub the stained area. Rinse the aluminum sheet thoroughly after utilizing these acidic solutions. 7. After the cleaning process, it is crucial to completely dry the aluminum sheet to prevent the formation of water spots or streaks. This can be achieved by using a clean towel or allowing the sheet to air dry. Always remember to test any cleaning solution or method on a small, inconspicuous area of the aluminum sheet before applying it to the entire surface. This will help ensure that no damage or discoloration occurs.

- Q: What are the different surface finishes for aluminum sheets in the aerospace industry?

- Aluminum sheets are widely used in the aerospace industry for constructing aircraft structures due to their lightweight and high strength. Various surface finishes can be applied to these sheets to enhance durability, protect against corrosion, and improve appearance. Anodizing is a commonly used finish that involves coating the aluminum with a protective oxide layer through electrolysis. This process not only improves corrosion resistance but also offers a range of color options and enhances adhesive acceptance. Another popular finish is alclad, which bonds a thin layer of pure aluminum to both sides of an alloy sheet. This provides excellent corrosion resistance and allows for better bonding with composite materials. Chemical conversion coatings are also used in the aerospace industry to provide corrosion resistance and improve paint adhesion. Mechanical finishes like grinding or brushing can be used for aesthetic purposes or to prepare the surface for further treatment. Specialized finishes are employed for specific applications. For areas with high wear resistance requirements, hard anodizing creates a durable surface. For parts needing low friction or high lubricity, a Teflon coating or dry film lubricant can be applied. The choice of surface finish for aluminum sheets in the aerospace industry depends on the specific application's requirements, including factors such as corrosion resistance, adhesion properties, wear resistance, and aesthetic preferences.

- Q: Can aluminum sheets be used for outdoor furniture?

- Yes, aluminum sheets can be used for outdoor furniture. Aluminum is a popular choice for outdoor furniture due to its durability, lightweight nature, and resistance to rust and corrosion. It can withstand various weather conditions, making it suitable for outdoor use. Additionally, aluminum can be easily molded and shaped into different designs, allowing for a wide range of furniture styles. The use of aluminum sheets in outdoor furniture ensures longevity and aesthetic appeal, making it a practical and versatile choice for outdoor settings.

- Q: How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q: I recently moved into a 1975 house with aluminum wiring. I will be going through and checking/replacing all receptacles and switches with CO/ALR rated ones as I don't have a budget right now to rewire the house. I am wondering if I should be checking all of the ceiling lights as well as some of them would be very difficult to access. Are lights as big a concern with aluminum connections as receptacles? I am sure some of the lights are newer and would have copper wire connected to the aluminum. Should I be concerned about the type of wire nuts used here?Anything else that I should be checking?

- There's no problem with aluminum wiring that would require you to rewire your house as long as the proper wire gauge was used. You should replace all of the receptacles and switches with ones rated CO/AL. For lighting, replace the wirenuts with ones rated CO/AL and you'll be fine. From what I remember, Aluminum has a higher resistance than copper so it requires 1 size larger conductors. Aluminum also oxidizes faster than copper. If you have aluminum wires in your panel you should turn the main service disconnect off and put some de-oxidizer (you can find it at home improvement stores in the electrical section) where the wire lug is. This oxidation can make a bad connection causing you to lose voltage as the resistance goes up raising the amperage. This will generate more heat. Aluminum also... well its hard to explain... A/C current cycles its power in a sin wave, it causes the wire to vibrate. You will have to tighten all of the lugs on your electric panel periodically. The CO/AL wirenuts and receptacles/switches help prevent the vibration from loosening the connections causing a short and possibly a shock hazard or even a fire.

- Q: Can aluminum plate protect against radiation?

- It can only about radiation, and other materials have not heard of this performance.

Send your message to us

Brushed Gold Anodized Direct Casting Mill Finished Aluminium Strips AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords