Aluminum Bendable Strips - Mill Finished Aluminum Strips AA1xxx for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Mill Finished Aluminum Strips AA1xxx USed for Construction Description

Mill Finished Aluminum Strips AA1xxx USed for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. Mill Finished Aluminum Strips AA1xxx USed for Construction is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminum Strips AA1xxx USed for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

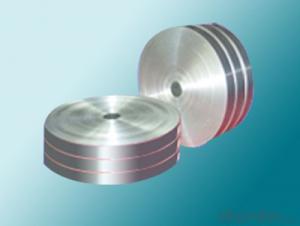

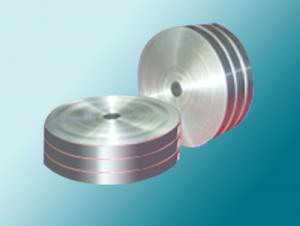

3. Image of Mill Finished Aluminum Strips AA1xxx USed for Construction

4. Product Specification of Mill Finished Aluminum Strips AA1xxx USed for Construction

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: The question asks if it's possible to use aluminum strips for insulating the exterior walls of a building.

- <p>Yes, aluminum strips can be used for exterior wall insulation, but they are typically used as a vapor barrier or as part of a metal stud framing system rather than as an insulating material themselves. Aluminum is a good conductor of heat, so it's not an insulator. Instead, it's often used to create a barrier against moisture and air infiltration. For insulation, materials like fiberglass, cellulose, or foam are more appropriate. Aluminum strips can help secure insulation boards in place and provide a base for attaching exterior finishes.</p>

- Q: What benefits does using aluminum strips provide compared to other materials?

- <p>Aluminum strips offer several advantages over other materials, including high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. They are lightweight, which is beneficial for reducing the weight of structures or products. Aluminum's resistance to corrosion means it requires less maintenance and has a longer lifespan. Additionally, its thermal conductivity makes it suitable for applications where heat transfer is important, such as in heat sinks or cookware. Aluminum strips are also easy to work with, allowing for easy fabrication and customization, and they are cost-effective, making them a popular choice in various industries.</p>

- Q: What unique considerations must be taken into account when storing and transporting aluminum strip stock?

- <p>Yes, there are special requirements for storing and transporting aluminum strip stock. Aluminum is sensitive to moisture and can corrode, so it must be kept dry. It's also important to avoid scratches and dents, which can occur if the material is mishandled. Aluminum strip stock should be stored in a clean, dry environment, away from chemicals that could cause corrosion. When transporting, it should be secured to prevent movement that could lead to damage. Protective coverings or wrappings are often used to shield the material from the elements and potential physical impacts.</p>

- Q: This question asks for a method to determine the weight of a specific length of aluminum strip.

- <p>To calculate the weight of a certain length of aluminum strip, you need to know the strip's length, width, thickness, and the density of aluminum. The density of aluminum is approximately 2700 kg/m鲁. The formula to calculate the weight is: Weight = (Length 脳 Width 脳 Thickness 脳 Density) / 1000. Convert all measurements to consistent units (SI units are preferred). For example, if you have a strip that is 1 meter long, 0.01 meters wide, and 0.001 meters thick, the weight would be calculated as follows: (1 脳 0.01 脳 0.001 脳 2700) / 1000 = 0.027 kg.</p>

- Q: Is it possible to use aluminum strips to construct a solar reflector system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a solar reflector system for your home or business. Aluminum is a reflective material and can be shaped into strips to reflect sunlight. These strips can be arranged in a way to direct sunlight towards solar panels or into specific areas to reduce the need for artificial lighting and heating. However, for optimal efficiency, you should consider the angle of reflection, the positioning of the strips relative to the sun's path, and the overall design of the system. Consulting with a professional in solar technology can help ensure that your solar reflector system is effective and safe.</p>

- Q: What are the regular maintenance concerns associated with aluminum siding on buildings?

- <p>Aluminum siding is generally low-maintenance, but there are a few issues that may require attention. These include checking for dents or damage caused by impacts, ensuring proper drainage to prevent water damage, and cleaning to remove dirt and grime that can dull the finish. Additionally, it's important to inspect for signs of corrosion, especially in coastal areas with high salt content, and to address any loose or peeling paint to prevent further damage. Regular inspection and minor repairs can help maintain the longevity and appearance of aluminum siding.</p>

- Q: What are the cost differences between aluminum and aluminum strips?

- <p>Aluminum and aluminum strips are both made from the same base material, but their costs can differ due to several factors. Aluminum strips are typically more expensive than bulk aluminum due to the additional processing and manufacturing steps involved in creating them. These steps include rolling, cutting, and sometimes surface treatments, which add to the cost. Additionally, aluminum strips often have tighter tolerances and specific dimensions, which can also increase their price. However, the exact cost difference can vary based on factors such as market prices for aluminum, the complexity of the strip's specifications, and the quantity purchased.</p>

- Q: This question asks about the durability and strength of aluminum strips for outdoor applications.

- <p>Aluminum strips are indeed strong enough for exterior use. They are lightweight, corrosion-resistant, and have high tensile strength, making them suitable for various outdoor applications such as siding, roofing, and fencing. Their resistance to weathering and low maintenance requirements add to their popularity in exterior settings. However, the specific strength and durability can vary based on the alloy composition and thickness of the strips, so it's important to select the appropriate grade of aluminum for the intended use.</p>

- Q: This question asks for a method to measure the width of aluminum strips.

- <p>To measure the width of aluminum strips, you can use a digital caliper or a micrometer, which are precise measuring tools. Place the strip between the jaws of the caliper and ensure it is aligned with the jaws' edges. Take the measurement at the widest point of the strip. If a caliper isn't available, you can use a ruler or tape measure, but this may be less accurate. For consistent measurements, measure the strip at multiple points to account for any variations in width.</p>

- Q: What is the standard thickness for aluminum strips and what is it commonly used for?

- <p>The thickness of aluminum strips can vary widely depending on their application, but common thicknesses range from 0.005 inches (0.127 mm) to 0.5 inches (12.7 mm). Aluminum strips are typically used in various industries such as construction, automotive, aerospace, and packaging. They are utilized for manufacturing parts, creating foils, and in applications requiring lightweight, strong, and corrosion-resistant materials.</p>

Send your message to us

Aluminum Bendable Strips - Mill Finished Aluminum Strips AA1xxx for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords