8ft by 5 Ft Honeycomb Aluminum Sheets - Direct Casting Aluminium Strip in Coils AA1050 6mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Direct Casting Aluminium Strip in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

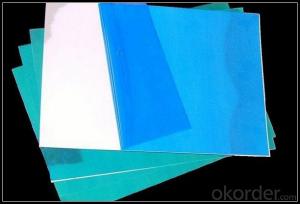

3. Image

4. Product Specification

| ALLOY | Temper | Thickness | Width | Weight |

| AA1050 | F | 3MM-8MM | 1200MM-1800MM | Min 5 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the cost of aluminum sheets compared to other metals?

- The cost of aluminum sheets is generally lower compared to other metals such as stainless steel or copper. Aluminum is a widely available and abundant material, which contributes to its relatively affordable price in comparison to other metals.

- Q: write a balanced equation for the reaction between aluminium metal and potassium hydroxide in water

- Potassium Aluminum Hydroxide

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be and are commonly used in food packaging. Aluminum is a popular choice for food packaging due to its excellent barrier properties, which protect the food from light, oxygen, moisture, and other external factors that can spoil or contaminate it. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them suitable for various types of food packaging, such as foil wraps, containers, trays, and pouches. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for food packaging.

- Q: what's the size of aluminum sheet circle?

- aluminum sheet circle's texture 1060, 3003 thickness 0.4-5.0mm, diameter 190-760mm.

- Q: How could two pieces of aluminium flakes be welded together?

- its welding strength is very high. you can use the following methods to weld two pieces of aluminum sheets together: 1, strict deformation control requirement. 3, it can prevent some flux remnant during welding. 3,the welding wire welding of low temperature M51 and M51-F is operated under 179?C.or they are welded in the situation of being especially thin.4, it can solve the welding of 3 series aluminium alloys and casting, and its welding temperature is 380-400?C.its advantage is that you don't need any flux during welding. WE53 low temperature aluminium welding wire has a high affinity in welding 7 series aluminium alloys. and Q303 low temperature aluminum welding wire has a high affinity for the welding of 1 series aluminium alloys, die casting or 6 series welding materials.

- Q: Can aluminum sheets be custom cut to specific sizes?

- Indeed, specific sizes can be achieved through the customization of aluminum sheets. Possessing great versatility, aluminum proves itself as a material that can be effortlessly shaped and cut to meet particular needs. By utilizing appropriate tools and equipment, one can achieve precise cuts on aluminum sheets, regardless of their purpose in industrial, commercial, or personal settings. This adaptability allows for the tailoring of aluminum sheets to suit specific applications, rendering it a favored option across various industries such as construction, automotive, and aerospace. Whether one requires compact or expansive aluminum sheets, they can be conveniently tailored to the precise dimensions necessary, guaranteeing an accurate fit for any given project or application.

- Q: How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets generally exhibit excellent water resistance due to their natural oxide layer, which forms a protective barrier against corrosion. This oxide layer prevents water from penetrating the surface, making aluminum sheets highly resistant to water damage and rusting.

- Q: How is the thickness of an aluminum sheet measured?

- The thickness of an aluminum sheet is typically measured using a tool called a micrometer. This handheld device applies pressure to the sheet and displays the measurement in millimeters or inches on a digital or analog gauge.

- Q: Trying to find the best aluminum powder I can buy for rocket engines and pyrotechnic (fireworks) uses?

- For okorder (I think there prices are the same as the other high end brands, except Star Molecule is not diluted, and it works better from my experience).

- Q: How does the purity of aluminum affect its properties as a sheet?

- The purity of aluminum greatly affects its properties as a sheet. Higher purity levels result in increased strength, improved corrosion resistance, and enhanced conductivity. Pure aluminum sheets are softer and more malleable, making them easier to form and shape. However, impurities can negatively impact these properties, reducing strength and increasing susceptibility to corrosion. Therefore, maintaining high purity levels is essential for achieving desired sheet properties and performance.

Send your message to us

8ft by 5 Ft Honeycomb Aluminum Sheets - Direct Casting Aluminium Strip in Coils AA1050 6mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords