Aluminum Sheets for Enclosed Trailers - Direct Casting Aluminium Coils for Food Pot AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Direct Casting Aluminium Coils for Food Pot AA1050

Direct Casting Aluminium Coils for Food Pot AA1050 for Re-rolling are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Direct Casting Aluminium Coils for Food Pot AA1050

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

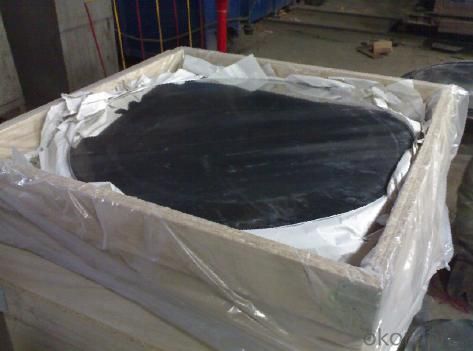

3. Image of Direct Casting Aluminium Coils for Food Pot AA1050

4. Product Specification of Direct Casting Aluminium Coils for Food Pot AA1050

| Alloy | Temper | Rolling | Thickness | Width |

| AA1050 | F | Hot Rolled | 0.2MM-2MM | 1000MM-1500MM |

5.FAQ of Direct Casting Aluminium Coils for Food Pot AA1050

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the various color and pattern options for aluminum sheets?

- <p>Aluminum sheets are available in a wide range of colors and patterns to suit various applications and aesthetic preferences. Colors can include silver, white, black, bronze, and many other shades. Patterns can range from simple matte or gloss finishes to more complex textures like wood grain, stone, and brushed metal effects. Some aluminum sheets also feature anodized finishes for enhanced durability and color vibrancy. Custom colors and patterns can be created through specialized coating processes, allowing for a high level of personalization in design and construction projects.</p>

- Q: Are aluminum sheets fire-resistant?

- Aluminum sheets possess properties that enhance their fire resistance when compared to other materials, although they are not inherently fire-resistant. With a melting point of 1220°F (660°C), aluminum exhibits a resistance to ignition and burning in normal conditions. Moreover, when heated, aluminum does not emit flammable gases and has a low ignition temperature. When subjected to fire, aluminum sheets form a protective oxide layer that functions as a barrier, impeding further combustion and slowing the propagation of flames. This oxide layer also serves as insulation, safeguarding the aluminum from heat and diminishing the risk of structural failure. Nevertheless, it is crucial to acknowledge that despite aluminum sheets surpassing the fire resistance of materials like wood or plastic, intense heat can still cause damage or deformation. Consequently, it is imperative to consider alternative fire safety measures, including the utilization of fire-resistant coatings or the integration of fire suppression systems, to ensure optimal protection against fire hazards.

- Q: Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q: Can aluminum sheets be used for protective enclosures?

- Aluminum sheets have the ability to be utilized for protective enclosures. This material, known for its versatility and lightweight nature, offers exceptional durability and resistance to corrosion. It can easily be transformed into various shapes and sizes, making it suitable for constructing protective enclosures across a wide range of applications. Industries such as electronics, telecommunications, aerospace, and automotive commonly employ aluminum enclosures, which safeguard against environmental factors like moisture, dust, and electromagnetic interference. Moreover, these enclosures can be further improved with the addition of coatings or insulation materials to meet specific requirements for thermal insulation, fire resistance, or electrical conductivity. All in all, aluminum sheets are a dependable option for protective enclosures due to their strength, adaptability, and capacity to endure challenging conditions.

- Q: i heard that aluminum causes Alzheimers and i was wondering if there is any aluminum in tin.

- No Aluminium (Al) is an element with atomic number 13. Tin (Sn) is another element with atomic number 50

- Q: Do aluminum cans melt in typical campfires? I know the melting point is about 660 Celsius but do campfires get that high? I thought it would just be that the can becomes disfigured and collapses due to the heat, not due to it melting. Even if it did melt in the fire how would you find the remains? The can in a liquid form would certainly not be confined to one part of the fire and therefore wouldn't solidify in a small pool to see if it had melted or not. Any ideas?

- Typical campfires do not get that hot. The can can become disfigured but it wont completely melt.

- Q: aluminum is produced by breaking down the compound...

- Bauxite is the most important aluminum ore. It consists largely of the minerals gibbsite Al(OH)3, boehmite γ-AlO(OH), and diaspore α-AlO(OH), together with the iron oxides goethite and hematite, the clay mineral kaolinite and small amounts of anatase TiO2. You have an unusual way of asking that question. Aluminum is an element and cannot be broken down accept to sub-atomic particles.

- Q: What rules or guidelines exist for using recycled aluminum sheets in construction projects?

- <p>Yes, there are regulations and guidelines regarding the use of recycled aluminum sheets in construction. These often include standards for material quality, safety, and environmental impact. The American Society for Testing and Materials (ASTM) and the Aluminum Association provide specifications for recycled aluminum alloys used in construction. Compliance with building codes and local regulations is essential. Additionally, recycled aluminum must meet performance and safety standards equivalent to those of new materials. It's crucial to check with local building authorities and consult the latest industry standards to ensure compliance when using recycled aluminum in construction.</p>

- Q: What are the applications of aluminum sheet?

- Aluminum sheets have a wide range of applications due to their various desirable properties. They are commonly used in the aerospace industry for aircraft construction, as well as in the automotive industry for body panels and structural components. Aluminum sheets are also used in the construction industry for roofing, siding, and insulation purposes. Additionally, they are utilized in the packaging industry for cans and foils, and in the electrical industry for wiring and conductors.

- Q: Can aluminum sheets be plasma cut?

- Indeed, aluminum sheets are able to undergo plasma cutting. The technique of plasma cutting presents itself as a versatile and highly effective method capable of cutting various materials, including aluminum, with great efficiency. By utilizing a high-speed stream of ionized gas, commonly referred to as plasma, the aluminum sheet can be meticulously shaped and tailored to meet specific requirements. Plasma cutting boasts a multitude of advantages, such as faster cutting speeds, more precise cuts, and significantly reduced heat-affected zones, in contrast to traditional cutting methods. As a result, it has become a widely utilized technique in numerous industries, including automotive, aerospace, and construction, for the purpose of cutting aluminum sheets of varying thicknesses.

Send your message to us

Aluminum Sheets for Enclosed Trailers - Direct Casting Aluminium Coils for Food Pot AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords