Corrugated Roofing Sheet Color Coated Steel Coil PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated Roofing Sheet/Color Coated Steel Coil/ppgi

1.Application

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

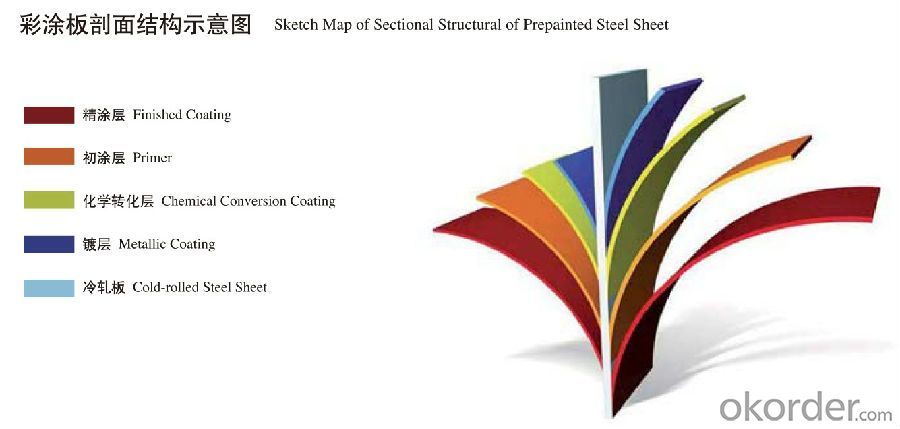

2.Features

With excellent cold-rolling steel strips as base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

3.Product Details

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Spangle | Regular/Zero/Big |

Color | All RAL Color,or be customized |

Coil ID | 508mm&610mm |

4. Image:

5. Production Line

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I'm talking about the sort of carbon fiber that's used in the auto industry (mostly in supercars).If an object made of steel were to be copied by an exact same object, but made of carbon fiber - how lighter would the carbon fiber object be?For example, if a table is made of steel and it weighs X, how much will it weigh if it were made of carbon fiber?Thanks.

- by 6L8

- Q: What are the advantages of using hot-rolled steel coils?

- Hot-rolled steel coils offer several advantages, including improved strength, durability, and formability. The high temperature during the rolling process allows for better shaping and molding, making it suitable for various applications. Additionally, hot-rolled steel coils have a smoother surface finish and are more cost-effective compared to cold-rolled steel coils.

- Q: How can the quality of steel coils be ensured?

- The quality of steel coils can be ensured through a combination of rigorous testing, adherence to industry standards, and effective quality control measures throughout the manufacturing process. This includes conducting various tests such as chemical composition analysis, mechanical property testing, and surface inspection to verify the integrity and durability of the steel coils. Additionally, implementing strict quality control protocols, regular inspections, and continuous improvement initiatives are essential to ensure consistent and high-quality production of steel coils.

- Q: How are steel coils used in the manufacturing of railroads?

- Steel coils are used in the manufacturing of railroads to produce rails, which form the tracks that trains run on. These coils are rolled into long, straight sections and then shaped into the required rail profile. The rails are then cut to the desired length and undergo various processes, such as heat treatment and finishing, to enhance their strength and durability. Overall, steel coils are a crucial raw material in the creation of reliable and robust railroad infrastructure.

- Q: What are the different types of steel coil recoiling methods?

- There are several different types of steel coil recoiling methods, including slitting, cut-to-length, and multi-blanking.

- Q: What are the different types of steel coil coating materials?

- There exist various steel coil coating materials utilized in diverse industries and applications. Some frequently encountered types encompass: 1. Polyester: Renowned for their resilience and ability to withstand weathering, polyester coil coating materials find frequent application in outdoor settings like roofing and cladding. They offer exceptional protection against fading, chalking, and corrosion. 2. Polyvinylidene Fluoride (PVDF): PVDF coil coating materials exhibit remarkable resistance to chemicals, UV radiation, and weathering. They are commonly employed in architectural contexts, providing prolonged color retention and excellent defense against harsh environmental conditions. 3. Polyurethane: Possessing a high degree of flexibility and adhesion, polyurethane coil coating materials prove ideal for scenarios necessitating resistance to abrasion, impact, and bending. The automotive and appliance industries commonly rely on them. 4. Epoxy: Epoxy coil coating materials are celebrated for their remarkable adhesion and corrosion resistance. Industries such as metal furniture, storage tanks, and machinery frequently utilize them to ensure long-lasting protection against chemicals and abrasion. 5. Silicone Modified Polyester (SMP): SMP coil coating materials combine the robustness of polyester with the flexibility of silicone. They are prevalent in agricultural and industrial settings, offering outstanding resistance to chipping, cracking, and peeling. These merely serve as a few instances of the diverse array of steel coil coating materials currently available in the market. The selection of a coating material hinges upon the specific requirements of an application, including durability, weather resistance, chemical resistance, and aesthetics.

- Q: My 8-year-old and 9-year-old boys have approached me with an interesting question. Does fire burn steel? One says yes, the other says no. Help me to settle yet another debate :)

- no, fire MIGHT cause steel to oxidize, depending on the alloy, but think of steel as a block of ice. Steel melts at 2800 degrees F and boils and evaporates at 5400 degrees. Some metals like magnesium can possibly catch fire but not steel

- Q: How are steel coils used in the manufacturing of garage doors?

- Steel coils are used in the manufacturing of garage doors as they are the primary material for constructing the door panels. These coils are first formed into thin, flat sheets and then cut to the desired size. The sheets are then shaped and reinforced to create the panels that make up the structure of the garage door. The strength and durability of steel make it an ideal material for garage doors, providing security, insulation, and longevity.

- Q: How are steel coils used in the manufacturing of conveyor belts?

- Steel coils are used in the manufacturing of conveyor belts as they provide the necessary strength and durability required for transporting heavy loads. The steel coils are processed and shaped into strong, flat strips that are then woven or bonded onto the belt's surface, enhancing its strength and resistance to wear and tear. This ensures that the conveyor belt can efficiently and reliably carry materials across various industries, including mining, logistics, and manufacturing.

- Q: I have heard of Cold Rolled steel, Castle Forged steel and Valerian steel and i was just wondering the difference between them.I know Valerian steel is by far the strongest and durable but what about the other two types? Do you know because i haven't read all the books yet.

- Castle Forged Steel

Send your message to us

Corrugated Roofing Sheet Color Coated Steel Coil PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords