Color Coated Steel Coil Printed PPGI for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

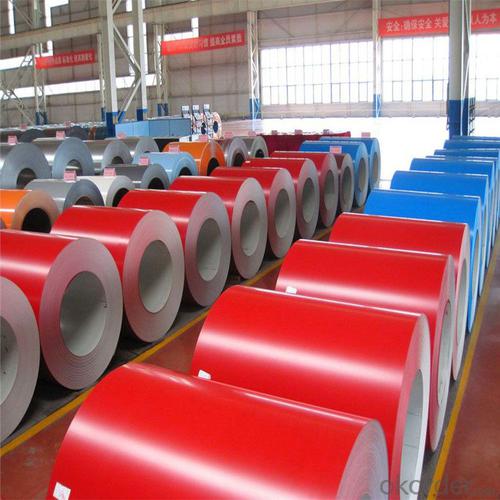

Color Coated Steel Coil Printed PPGI

Description of Color Coated Steel Coil Printed PPGI

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Color Coated Steel Coil Printed PPGI

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

Products Show of Color Coated Steel Coil Printed PPGI

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different cutting techniques used for special steel?

- Some of the different cutting techniques used for special steel include abrasive cutting, laser cutting, waterjet cutting, and flame cutting.

- Q: How does special steel perform in high-pressure applications?

- Special steel performs exceptionally well in high-pressure applications. Its unique properties, such as high strength, excellent corrosion resistance, and good thermal stability, make it an ideal choice for withstanding extreme pressure conditions. It maintains its structural integrity, preventing deformation or failure, even when exposed to intense pressure. Additionally, special steel's resistance to fatigue and wear ensures long-term performance and reliability in high-pressure environments.

- Q: How does special steel contribute to the power generation industry?

- Special steel plays a crucial role in the power generation industry by providing the necessary strength, durability, and resistance to extreme temperatures and corrosive environments. It is used in the construction of turbines, generators, and other critical components, ensuring the efficient and reliable operation of power plants. Additionally, special steel's high heat resistance and excellent mechanical properties enable power plants to operate at higher temperatures, increasing energy efficiency and reducing emissions.

- Q: What are the environmental impacts of producing special steel?

- The production of special steel can have several environmental impacts. Firstly, the extraction of raw materials, such as iron ore and coal, can lead to habitat destruction and soil erosion. Additionally, the energy-intensive processes involved in steel production, such as smelting and refining, contribute to greenhouse gas emissions, air pollution, and climate change. Moreover, the disposal of waste materials, including slag and dust, can contaminate water sources and harm aquatic life. It is crucial to implement sustainable practices and technologies to mitigate these environmental impacts and ensure responsible steel production.

- Q: How does special steel perform in medical applications?

- Special steel performs exceptionally well in medical applications due to its unique properties. It offers high strength, durability, and corrosion resistance, making it ideal for surgical instruments, implants, and medical devices. Special steel's biocompatibility ensures it doesn't react with body tissues, reducing the risk of complications or adverse reactions. Additionally, its malleability allows for precise shaping, facilitating the production of complex medical tools. Overall, special steel contributes to the efficiency and reliability of medical procedures, improving patient outcomes.

- Q: What are the magnetic properties of special steel?

- Special steel can exhibit a range of magnetic properties depending on its composition and processing. It can be non-magnetic, weakly magnetic, or strongly magnetic. The specific magnetic properties of special steel can be tailored to meet specific requirements for different applications.

- Q: What are the environmental impacts of using special steel?

- The environmental impacts of using special steel can vary depending on factors such as the production process, sourcing of raw materials, and waste management practices. However, some common environmental impacts associated with special steel production include carbon dioxide emissions, energy consumption, water pollution, and habitat destruction. Special steel often requires high energy inputs and releases significant amounts of greenhouse gases during production, contributing to climate change. Additionally, the extraction and processing of raw materials used in special steel production can lead to water pollution and habitat degradation if not managed properly. It is important for industries to adopt sustainable practices and technologies to minimize these environmental impacts and promote a more sustainable use of special steel.

- Q: Can special steel be used in food processing applications?

- Yes, special steel can be used in food processing applications. Special steel, such as stainless steel, is commonly used in the food industry due to its excellent corrosion resistance, hygienic properties, and durability. It is safe for food contact, easy to clean, and does not react with acidic or alkaline substances.

- Q: Can special steel be used for aerospace engine components?

- Yes, special steel can be used for aerospace engine components. Special steel alloys, such as nickel-based superalloys, are often used in the manufacturing of aerospace engine components due to their excellent high-temperature strength, corrosion resistance, and ability to withstand extreme conditions. These steel alloys are specifically designed to meet the stringent requirements and demands of aerospace applications, ensuring optimal performance and reliability of the engine components.

- Q: How does special steel contribute to improving product performance in corrosive environments?

- Special steel contributes to improving product performance in corrosive environments due to its unique properties and composition. Special steel is specifically designed to resist corrosion and maintain its structural integrity even when exposed to harsh conditions. It contains elements like chromium, nickel, and molybdenum that form a protective layer on the surface, preventing the metal from reacting with corrosive substances. This enhanced corrosion resistance ensures that products made from special steel have a longer lifespan, reduced maintenance requirements, and improved performance in corrosive environments.

Send your message to us

Color Coated Steel Coil Printed PPGI for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords