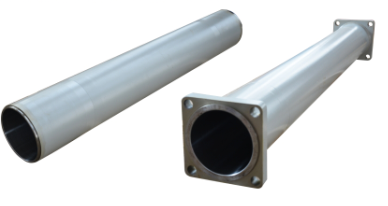

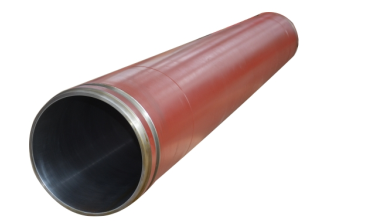

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:2022MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN200*2022

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN200*2022

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Where can I buy concrete pump spare parts?

- Concrete pump spare parts can be purchased from various sources. One possibility is to contact the manufacturer of your concrete pump. Typically, they have authorized dealers or distributors who sell genuine spare parts for their equipment. This guarantees that the parts are of high quality and compatible with your specific pump model. Another option is to explore specialized construction equipment suppliers or dealers in your locality. These companies often carry a wide range of spare parts for different types and brands of concrete pumps. You may either visit their physical stores or browse their websites to check if they have the specific parts you require. Alternatively, online marketplaces and platforms offer a convenient way to buy concrete pump spare parts. Websites such as Amazon, eBay, and Alibaba have an extensive selection of spare parts from sellers worldwide. You have the opportunity to compare prices, read reviews, and select the parts that best meet your needs. Before finalizing your purchase, it is crucial to ensure that you are buying from a reputable source. Look for sellers with positive feedback or ratings, and verify if they provide warranties or return policies. Additionally, take into account factors like shipping costs, delivery times, and customer service when determining where to purchase your concrete pump spare parts.

- Q: What is the function of a concrete pump hydraulic filter?

- The concrete pump hydraulic filter serves to eliminate impurities and contaminants from the hydraulic fluid, which is responsible for the pump's operation. Its purpose is to capture particles like dirt, debris, and metal fragments that might be in the hydraulic system. By removing these contaminants, the filter guarantees that the hydraulic fluid remains clean and devoid of any harmful particles that could cause damage. This, in turn, keeps the concrete pump functioning smoothly and for a longer period of time, as it prevents blockages, wear and tear, and potential harm to the hydraulic components. Furthermore, a clean hydraulic system minimizes the risk of hydraulic fluid leakage, which can result in expensive repairs and downtime. Hence, the concrete pump hydraulic filter is crucial in ensuring the effectiveness, dependability, and resilience of the hydraulic system.

- Q: Can I get spare parts for concrete pump hydraulic cylinders and valves?

- Absolutely, spare parts for concrete pump hydraulic cylinders and valves are readily available. There is a wide range of companies and suppliers dedicated to supplying spare parts specifically for construction machinery, such as hydraulic cylinders and valves for concrete pumps. These spare parts can be conveniently obtained online or through nearby distributors. To ensure compatibility and proper operation of the spare parts, it is crucial to provide precise details about the make and model of your concrete pump. Furthermore, it is recommended to select reputable suppliers who offer authentic, top-notch spare parts for optimal performance and longevity.

- Q: What are the indicators of a faulty concrete pump seal?

- There are several indicators that can suggest a faulty concrete pump seal. These include: 1. Leakage: One of the most obvious signs of a faulty seal is leakage of concrete or water around the seal area. If you notice any fluid seeping out from the seal, it is a clear indication of a problem. 2. Reduced pumping efficiency: A faulty seal can result in reduced pumping efficiency. If you notice that the concrete pump is not delivering the expected amount of concrete or is struggling to pump the material, it could be due to a seal issue. 3. Increased noise and vibration: A faulty seal can cause increased noise and vibration during the operation of the concrete pump. Unusual sounds or excessive vibration can indicate that the seal is not functioning properly, and further inspection may be required. 4. Premature wear and tear: If the seal is faulty, it can lead to premature wear and tear of other components in the pump system. This can be observed through the degradation of other parts such as gaskets, bearings, or pistons. Regular inspections can help identify such issues. 5. Inconsistent pressure: A faulty seal can result in inconsistent pressure while pumping concrete. If you notice variations in the pressure output or irregular flow of concrete, it may be a sign of a seal problem. 6. Excessive heat: Another indicator of a faulty seal is the generation of excessive heat in the seal area. If the seal is not functioning properly, it can cause friction and heat buildup, which can be felt or observed by touch. It is important to address any indication of a faulty concrete pump seal promptly to prevent further damage to the pump system and ensure the safety and efficiency of the operation. Consulting a professional or contacting the manufacturer for guidance and repair is recommended in such cases.

- Q: Can concrete pump spare parts be resold or traded in for new parts?

- Yes, concrete pump spare parts can be resold or traded in for new parts. Many suppliers and manufacturers offer buyback or exchange programs where customers can return their used parts and receive credit towards purchasing new ones. Reselling used parts is also common in the construction industry, as there is a demand for affordable alternatives to new parts. However, the resale value may vary depending on the condition and market demand for specific spare parts.

- Q: Are there any specific guidelines for the installation of pipe or hose assemblies in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of pipe or hose assemblies in concrete pump spare parts. These guidelines ensure proper installation techniques are followed to ensure the assemblies are securely and correctly installed. It is important to consult the manufacturer's instructions and adhere to industry standards to ensure optimal performance and safety of the concrete pump spare parts.

- Q: How can a faulty concrete pump S valve affect the concrete flow?

- A faulty concrete pump S valve can affect the concrete flow by causing disruptions, blockages, or uneven distribution of the concrete. The S valve is responsible for controlling the direction of the concrete flow, and when it malfunctions, it can lead to decreased or inconsistent flow rates. This can result in delays in the construction process, poor concrete quality, or even damage to the pump system.

- Q: What are the signs of a faulty concrete pump control box?

- Some signs of a faulty concrete pump control box may include malfunctioning buttons or switches, erratic or inconsistent pump operation, failure to start or stop the pump, and abnormal or unusual sounds coming from the control box. Additionally, if there are any visible signs of damage, such as loose wires or burnt components, it could indicate a problem with the control box.

- Q: How do I properly maintain and replace rubber pistons in concrete pump spare parts?

- Proper maintenance and replacement of rubber pistons in concrete pump spare parts involves a few key steps. Firstly, make sure to regularly inspect the pistons for any signs of wear, such as cracks or tears. It is recommended to replace them if they are significantly worn or damaged. To replace the rubber pistons, start by removing the old piston carefully, ensuring not to damage the cylinder or any other components. Clean the cylinder thoroughly, removing any debris or residue. Apply a lubricant or concrete pump primer to the cylinder walls to aid in the installation of the new piston. Next, carefully install the new rubber piston, ensuring it is properly aligned with the cylinder. Gently push it into place, avoiding any unnecessary force that could cause damage. It is important to refer to the manufacturer's instructions or guidelines for specific installation techniques. After replacing the rubber piston, run a few tests to ensure its proper functioning. Check for proper sealing and smooth operation by conducting a dry run or pumping a small amount of concrete. Monitor the piston's performance closely, and if any issues arise, consult a professional or the manufacturer for further guidance. Regular maintenance, such as cleaning the cylinder and lubricating the pistons, can help extend their lifespan. Additionally, following proper operating procedures, such as avoiding excessive pressure or abrasive materials, can also contribute to the longevity of rubber pistons.

- Q: How can a malfunctioning control panel affect the pump's operation?

- The operation of a pump can be negatively affected by a control panel that is not functioning properly. Firstly, the control panel is responsible for monitoring and controlling various functions of the pump, including starting, stopping, and regulating the flow of fluids. If the control panel malfunctions, it may not send accurate signals to the pump, resulting in erratic or incorrect operation. Furthermore, a malfunctioning control panel can cause a breakdown in communication between the pump and other components or systems. For example, if the control panel fails to transmit important information to the pump's sensors or other control devices, the pump may not be able to respond appropriately to changes in pressure, temperature, or flow rate. This can lead to inefficient performance, potential damage to the pump, or even complete failure. Moreover, the safety of the pump's operation can be compromised by a malfunctioning control panel. Control panels often include safety features such as emergency shutdowns or alarms to prevent hazardous situations. If these safety mechanisms are compromised due to a malfunction, it can increase the risk of accidents, equipment damage, or harm to personnel. In conclusion, a malfunctioning control panel can disrupt the proper functioning of a pump by causing operational inconsistencies, loss of communication with other components, decreased efficiency, increased risk of accidents, and potential damage to the pump itself. Therefore, it is essential to regularly inspect and maintain control panels to ensure they function properly and minimize the chances of any negative impact on the pump's operation.

Send your message to us

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:2022MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords